Maverick Spend

‘Strategic Sourcing’ has played a key role in the success of procurement teams. A dent in this key game plan is “maverick spending.”

How It Happens and How to Counteract

Procurement is rising on the priority lists of both corporations and governments. The two foremost examples that I can think of are:

- In December 2014, the US government reported a reduction of more than USD 55 billion in contract savings in fiscal year 2013 over the previous year. The savings was part of a four-year decrease in the cost of federal contracting.

- Novartis, a global healthcare company, has reported procurement savings of USD 1.6 billion in 2014 and is expected to see even greater procurement savings in 2015.

‘Strategic Sourcing’ has played a key role in the success of procurement teams in both of the above-mentioned cases. A dent in this key game plan is “maverick spending.”

Maverick spending can be defined as a purchase made outside of the preferred route. These are ad-hoc purchases, made outside a negotiated contract with a preferred supplier. I will discuss maverick spending and countermeasures in relation to the pharmaceutical industry in order to understand it better.

How much does an organization really lose?

Direct capital loss

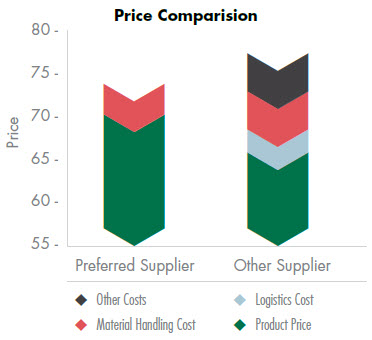

Maverick spending is overspending. During negotiation, procurement teams not only negotiate the product prices but also work on other charges such as logistical costs based on the total volume of business. If the buyer got a deal where the product price offered by the new supplier is lower than the discounted price quoted by the preferred supplier, then two things must be checked:

- Additional costs such as logistical costs, material handling costs, and quality assurance costs

- Future relationship with the preferred buyer, which is important in case of a product supply shortage and when return policies are tested

Related Article: Empowering Employees to Achieve Cost Savings

Impact on financial planning

Source: Beroe Inc.Another big issue is the impact of maverick spending on yearly financial planning. Contract spending is tracked by a pre-defined procedure having checkpoints for proper monitoring. But in the case of maverick spending, purchasing channels are opaque. It is difficult for the procurement department to track this spending.

Source: Beroe Inc.Another big issue is the impact of maverick spending on yearly financial planning. Contract spending is tracked by a pre-defined procedure having checkpoints for proper monitoring. But in the case of maverick spending, purchasing channels are opaque. It is difficult for the procurement department to track this spending.

Productivity loss

Other than direct capital losses, a big cost of maverick spending is time. Often maverick purchasing is made by the individual responsible for other core activities. For example, a scientist purchasing lab consumables. As soon as these individuals shift from their core activity to a non-core activity, it’s a productivity loss for the whole organization. In the case of an intensive R&D environment as found in the pharmaceutical industry, loss of productivity is a huge cost.

Why does maverick spending occur?

A scientist going out of his core zone and getting involved in purchasing raises questions about the whole procurement process. There are many possibilities that can cause such a situation, but the primary ones are:

- Inventory is poorly managed

- The procurement process is highly complex

- The product is not available

- Non-procurement professionals have purchasing power

Inventory management

Double purchases have been observed across industries. Many times this is due to lack of proper inventory management practices. Professionals working on the floor took it upon themselves to purchase material to meet their immediate requirements. Two main checkpoints to avoid this are:

- There must be mandatory procedures in place to check the inventory before placing new orders.

- The inventory tracking procedures must be efficient and accessible enough to provide all required information about the individual and small items to the end-user. IT platforms play a major role in this.

Pharmaceutical labs use numerous chemicals in their daily operations. In a regulated environment, handling of highly diverse product lines is a very difficult task for procurement teams. Inventory management through automated systems has shown promising results in decreasing inventory management costs. It was observed that pharmaceutical labs manage to save around ten percent of the inventory management costs with effective chemical inventory management solutions.

Pharmaceutical labs use numerous chemicals in their daily operations. In a regulated environment, handling of highly diverse product lines is a very difficult task for procurement teams. Inventory management through automated systems has shown promising results in decreasing inventory management costs. It was observed that pharmaceutical labs manage to save around ten percent of the inventory management costs with effective chemical inventory management solutions.

Procurement complexity

Pharma companies are looking to increase R&D output, which requires optimizing scientists’ time. Complex purchasing processes and incomplete catalogs deter scientists from the established contract purchasing procedures and encourage them to explore other available options.

The procurement team must have regular feedback from internal stakeholders. This enables them to better understand the reasons behind ad hoc purchases. The procurement team can then work with external stakeholders, i.e., the supplier community, in designing efficient processes, correct inventory measures, and informative catalogs. Further, these insights help them design suitable training programs to equip the end-users with required purchasing skills.

Product availability

Supplier rationalization has led pharmaceutical organizations to become dependent on large distributors who manage the majority of consumables and supplies spending on their behalf. Similar trends have been observed in the MRO sector, where integrators manage the purchases on behalf of buyers. In this type of agreement, buyers go into long-duration contracts with the big distributors or integrators after price negotiation. The distributor manages the manufacturer’s catalog to facilitate direct end-user purchases.

But sometimes this one-stop-shop doesn’t work. Scientists prefer to use products (chemicals or reagents) that they trust or with which they have experience. In the event a desired catalog product is unavailable, scientists purchase the product through the open market. Sometimes the lead time is not aligned with the project requirement, pushing scientists to procure the product from other sources.

Purchasing power

In many organizations (especially public organizations) purchasing is an open process. Non-procurement personnel were allowed to purchase based on their discretion. Purchases were made through PO or P-cards (purchasing cards). P-card purchases make the situation worse, as they are hard to trace.

What is the solution?

From the above discussion it can be concluded that maverick spending is the result of the gap between operations and procurement teams. This lack of understanding of each other’s functions causes the damage. The procurement team must understand the operational value of their function and drive value out of the purchases rather than through cost savings. Maverick spending can be reduced by following these guidelines:

- The procurement team must develop clear value definition in conjunction with the operation team for achieving organization-wide goals.

- Non-procurement professionals must be trained in procurement procedures.

- Purchasing directions must be clearly developed at the organizational level with respect to inventory checks, purchasing permissions, and reporting.

- As much as possible, purchasing power must be restricted to the procurement team.

- P-card purchases must be restricted, regulated, and audited regularly.

- Suppliers must be audited to check the contract adherence and learn the gaps in delivery and requirements.

- The P2P process must be simplified and tailored according the needs of the end-user community.

It must be acknowledged that maverick spending cannot be avoided completely. Maverick spending is like friction, a necessary evil. It provides flexibility to the end-user to take the opportunity to experiment with new products. Sometimes, this small experimentation leads to identifying new products and suppliers that increase purchasing options for the organization in the future.

http://www.reuters.com/article/2015/01/27/idUSFWN-0V501Q20150127