Sustainable Science

Ensuring that both new and existing laboratories are environmentally sustainable is not just a trendy label—it is a necessity.

Changes That Can Benefit Both the Environment and Your Budget

Laboratories use a shockingly large amount of energy— roughly four times that of similarly sized offices. They are also very intensive: the labs at Harvard, for example, account for 44 percent of the university’s energy use but only occupy 20 percent of the space. Ensuring that both new and existing laboratories are environmentally sustainable is not just a trendy label—it is a necessity. The mounting pressure placed upon the environment in the form of gas, chemical, and even material waste is producing potentially irrevocable damage. While large-scale industry remains a major contributor to this issue, simply assigning blame in the hopes that someone else will resolve the issue is unacceptable. As members of a larger society, we each have a responsibility to make concerted efforts to ensure that sustainability is practiced wherever possible. Whether this means making sure the biological safety cabinets (BSCs) are optimized in small academic laboratories, or that mass production in an industrial facility adopts a zero waste approach, it is imperative that we begin to make changes.

What is sustainability?

Sustainability is simply about looking forward and making sure that we do remain viable. The Brundtland Commission defines it as “development that meets the needs of the present without compromising the ability of future generations to meet their own needs.”1 The United States Environmental Protection Agency (EPA) provides a lengthier description: “Sustainability is based on a simple principle: Everything that we need for our survival and well-being depends, either directly or indirectly, on our natural environment. To pursue sustainability is to create and maintain the conditions under which humans and nature can exist in productive harmony to support present and future generations.”2

Why do we need sustainable labs?

If you think about the sheer amount of equipment within even the most rudimentary lab, it quickly surpasses anything you will find in an office. A typical office space usually includes a collection of computers— likely to consume the most energy—a printer or two, a photocopier, and basic kitchen appliances such as a coffeemaker or refrigerator. Then, of course, there are the lighting and air-conditioning. A lab, on the other hand, includes all of these office essentials in addition to the equipment specific to a laboratory, such as magnetic stirrers and shakers that run almost continuously; PCR machines; microscopes and lasers; incubators, refrigerators, and freezers; BSCs; and the exceedingly important heating, ventilation, and air-conditioning (HVAC) system. Ventilation was in fact the most substantial drain on energy according to a report3 from Safe, Successful, and Sustainable Laboratories (S-Lab), an initiative of Higher Education for Environmental Performance Improvement (HEEPI), which found that ventilation alone used between 45 and 60 percent of energy in labs, compared with just 3 percent in a typical office.

Such extreme energy use not only incurs significant costs, but also results in thousands of tons of carbon being emitted into the atmosphere every year. Even equipment such as a -80 °C ultralow temperature (ULT) freezer generates around four metric tons of carbon dioxide every year, potentially costing as much as $1,200 in excess annually.4

It’s not just research labs, but also the laboratories involved in industrial-scale production, where the chemicals and materials used in manufacturing need to be stored, transported, and eventually disposed of. This can often mean dumping in landfills, where some of the waste products can take centuries to degrade. With landfill space actually running out and the list of materials that are banned from landfill steadily increasing, there is a need to find better solutions to manage harmful laboratory waste.

The global demand for energy and raw materials continues to grow, while supply struggles to keep up and finite resources become depleted. Alarm bells have been ringing for years, but only recently have they been heard. Thankfully, the response has been significant.

What are labs doing to remedy this?

The scientific community as a whole has been responding to the clear need for more sustainable approaches to life in the lab: this includes the equipment used, the materials disposed of, and the habits formed in daily routines. Initiatives, awards, and certifications have been devised to educate and incentivize all of those involved.

Featured Article: University Driven Green Lab Initiatives Continue to Point the Way

There have also been international efforts to understand and implement changes toward a more sustainable form of science. They have formed the basis of sustainability standards and certifications, including rating systems such as Leadership in Energy and Environmental Design (LEED), frequently used in assisting building designers, owners, and operators in achieving a responsible use of resources. The U.S. has even started incentivizing those adhering to these practices by having federal agencies or local governments reward or even require LEED certification for new buildings.

Academia

Academic labs have also been making waves in the area of sustainability. Numerous institutes have now adopted varying forms of the Green Labs Program, whereby the program leaders work with researchers, staff, faculty, and building managers to implement sustainable technologies. Lab members within the departments can submit themselves for an informal review of their practices to see how best to improve their activities.

Academic labs have also been making waves in the area of sustainability. Numerous institutes have now adopted varying forms of the Green Labs Program, whereby the program leaders work with researchers, staff, faculty, and building managers to implement sustainable technologies. Lab members within the departments can submit themselves for an informal review of their practices to see how best to improve their activities.

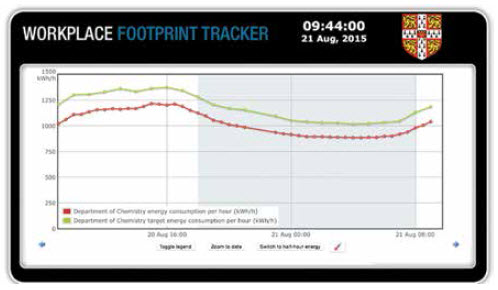

Other academic institutes have live energy consumption graphs5 accessible to the public, holding themselves accountable for how much energy specific labs are using. The University of Cambridge (UK) has this feature, and has also implemented something known as the Living Lab, a program that provides opportunities for students to propose and carry out projects across the university to improve sustainability.

Industry

In addition to certifications like LEED, there are also awards such as the Zero Waste Awards, held each year by the Environment Media Group in an attempt to acknowledge those making substantial contributions to reducing waste. They advocate the 3Rs of waste: reduction, reuse, and recycling. Their aim is “to close the loop, so recovered waste materials are fed back into the production cycle, creating a virtuous, closed circle, as in nature.” From a business perspective, companies can boldly proclaim their Zero Waste awards, identifying themselves as trailblazers on the path to sustainable industrial practices.

Zero waste programs have been a great eye-opener for many companies, helping them to save vast sums of money simply by adjusting some of their processes. For example, Thermo Fisher Scientific’s site in Asheville, NC, is a zero waste facility where 93 percent of the waste is recycled and the other 7 percent is entered into a waste-to-energy program. An additional site in Israel saved $27,000 annually simply by purchasing aluminum oxide in bulk, while the Frederick, MD, site saved $88,000 by purchasing preservation media in larger containers.6 With such notable savings, the desire to become sustainable also makes good business sense, resulting in a number of companies setting plans to reduce waste by up to 100 percent.

Individuals

Contributing to sustainability is not just restricted to the realm of institutes and industry— every individual has a role to play.

- Choose your chemicals with care. In most instances, researchers can avoid having to dispose of hazardous chemicals simply by making intelligent substitutions7: cyclohexane can often substitute for the more toxic benzene; hydrocarbon solvents can be used in place of their halogenated counterparts; and aqueous solvents are commonly replacing hydrocarbons as the reaction media of choice. MIT even has a Green Alternatives Wizard8 to help with selecting your reagents.

- Shut that sash! Fume hoods use vast amounts of energy and their exhausts generate a great deal of greenhouse emissions when not regulated, and more often than not, are left on. Labs like those at Harvard have implemented a program of competitions9, which now covers 19 labs and more than 350 researchers, to combat the high-energy consumption of variable air volume (VAV) fume hoods. In 2010, they saw a 30 percent reduction in fume hood exhaust levels, annual energy savings of over $240,000 at $7/cfm, and annual reductions of more than 300 metric tons of greenhouse gas emissions.

- Optimize your BSC. Like fume hoods, BSCs can use large amounts of energy. A review of 63 BSCs being used at a university showed that just a handful were accounting for almost all of the costs of running all 63.10 This can be improved by optimizing run procedures, using more energy-efficient models, or implementing reduced air flow options at night, for example. The survey highlights that by improving the efficiency of the 13 most costly BSCs by 50 percent, the cost of running all 63 BSCs could be reduced by 35 percent.10

Figure 1: Energy saving per box stored of several popular freezers presently available.Organize frozen samples. Standing in front of a ULT freezer with the door open as you hunt for samples results in a loss of energy and an elevation in cabinet temperature, forcing the freezer to work harder to maintain its temperature. You can avoid this by ensuring your samples are organized in a racking system and labeled, making them easy to retrieve. Alternatively, consider investing in an environmentally friendly ULT freezer that has advanced, variable speed compressors and sample management options. As shown in Figure 1, such an investment could help to reduce the amount of energy consumed and, as a result, yield cost savings of up to approximately $6,742 over a 10-year period.

Figure 1: Energy saving per box stored of several popular freezers presently available.Organize frozen samples. Standing in front of a ULT freezer with the door open as you hunt for samples results in a loss of energy and an elevation in cabinet temperature, forcing the freezer to work harder to maintain its temperature. You can avoid this by ensuring your samples are organized in a racking system and labeled, making them easy to retrieve. Alternatively, consider investing in an environmentally friendly ULT freezer that has advanced, variable speed compressors and sample management options. As shown in Figure 1, such an investment could help to reduce the amount of energy consumed and, as a result, yield cost savings of up to approximately $6,742 over a 10-year period.- Purchase wisely. If you’re responsible for purchasing and stock maintenance, consider making use of on-site stores or freezer programs in order to save on fuel and transport costs.

These are just a few examples of small changes that individual lab employees can make in order to bring about big changes.

A commitment to the future

Reconsidering daily activities in the lab, or changing engineering and architectural designs to meet new construction standards may seem like large undertakings, but implementing sustainability practices is worth the time. Making sure that your lab and your procedures are efficient and environmentally friendly will benefit the environment as well as your budget. Labs that make the effort to adjust how they manage their energy usage have seen significant savings. The University of Cambridge, UK, for example, introduced a shared cost/savings scheme11 in 2008 to reduce electricity consumption after their energy costs began increasing at an alarming rate. In just the first year, they halved the rate of electricity consumption, avoided the production of 3,852 tons of carbon dioxide emissions, and saved £0.82 ($1.29) million. By adopting sustainable approaches to designing and running a lab, lab managers can effectively create more funds for research and reduce the impact to the environment to help safeguard it for future generations.

References

1. http://www.un-documents.net/our-common-future.pdf

2. http://www2.epa.gov/sustainability/learn-about-sustainability#what

3. http://www.goodcampus.org/files/files/60-S-Lab_Energy_Audits_of_HE_Labs_final_v15_4_7_11.pdf

4. Calculated using data from the European Commission’s published electricity and natural gas price statistics, and assuming 0.0005925 metric tons of carbon dioxide/kWh; http://ec.europa.eu/eurostat/statistics-explained/index.php/Electricity_and_natural_gas_price_statistics

5. http://www.environment.admin.cam.ac.uk/what-are-we-doing/energy/energy-dashboards/gurdon-institute

6. https://corporate.thermofisher.com/en/about-us/zero-waste-smart-investment.html

7. https://www.acs.org/content/dam/acsorg/about/governance/committees/chemicalsafety/publications/less-isbetter.pdf

8. http://ehs.mit.edu/greenchem/

9. http://green.harvard.edu/programs/green-labs

10. Phillips, SD (2015) Class II Biosafety Cabinet Sustainability. In Anthology of Biosafety XIV: Sustainability. JY Richmond, J Jackman (eds), p151-159. American Biological Safety Association.

11. http://www.goodcampus.org/uploads/DOCS/106-case_8__-_Cambridge_incentives_final.pdf