How Preventing Instrument Maintenance Issues and Downtime Works

Unplanned and unexpected instrument downtime in a lab means delays and frustrations that can potentially damage a lab’s reputation to reliably deliver high-quality results.

Problem: Unplanned and unexpected instrument downtime in a lab means delays and frustrations that can potentially damage a lab’s reputation to reliably deliver high-quality results. A 2018 survey of 700 lab managers in four countries—conducted by market research firm Frost & Sullivan on behalf of Agilent Technologies—asked lab managers to rank their top five challenges.

Instrument maintenance and downtime topped the list at 73 percent. Regular instrument maintenance is essential for sustaining high instrument performance and minimizing costly unplanned downtime. But many variables, including high sample loads, multiple work shifts, and challenging operating conditions can drive the need for more frequent maintenance than just the basic manufacturer recommended intervals. Keeping track of all that can be a chore, especially when there are multiple instruments in the lab.

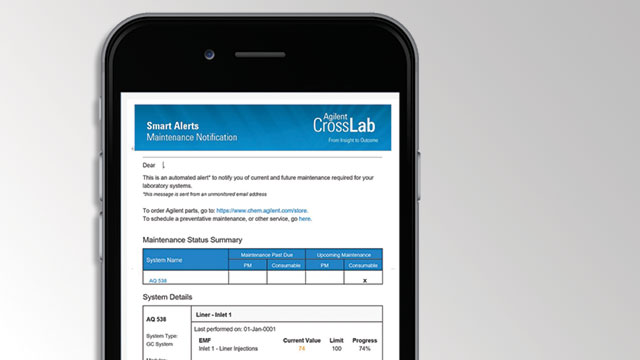

Solution: Agilent CrossLab Smart Alerts can help prevent the headache of GC instrument downtime. Smart Alerts is data-driven instrument maintenance software that monitors actual instrument usage, and provides timely recommendations based on long-term evaluation of instruments under different operating conditions. Smart Alerts can be loaded onto any PC in the lab, and then collects information known as Early Maintenance Feedback (EMF) from instruments across the lab. This data is compared against recommended application-specific limits. When an EMF limit is reached, an email is sent with a recommended action. The lab manager then decides what to do next. This may be replacing a consumable or performing or requesting preventative maintenance on the instrument. Active alerts are conveniently consolidated into a single email for connected instruments. Smart Alerts also provides “upcoming” alerts, so there is time to plan for instrument maintenance at a time that is convenient to lab operations. Incorporating a user-friendly interface, making expanded use of sensors and connectivity, and accessing real-time usage and performance data, the Smart Alerts dashboard provides a view of all instruments across the lab. This enables operators to monitor instrument status between email alerts and track active alerts independent of email. Lab managers can further customize Smart Alerts by adjusting EMF limits based on their own experience and expectations.

Staying ahead of the game with data-driven decisions is an important evolution of any lab’s workflow efficiency and diagnostics strategy. Smart Alerts can help a lab become a truly “smart connected lab.”

For more information, please visit www.agilent.com/crosslab-smart-alerts