Automated Liquid Handling

Options driven by specialized applications, cost of consumables and use of workspace

Manual pipetting, even using multichannel pipettes, is slow, monotonous and variable, and has the potential to cause repetitive stress injuries to laboratory workers. Automated liquid handling systems, on the other hand, are precise, accurate, fast and consistent. They also decrease errors within and between operations, help conserve expensive reagents and rare or hardto- produce samples, and save time.

Liquid handling systems are very diverse in their applications and cater to the throughput and speed of automation that the user needs. They range from single-channel pipetting systems to those with 8-, 96- or 384-channel pipette heads. Modules are also equipped to handle a wide range of volumes, from nanoliters to microliters. Generic operations performed by a liquid handler include serial dilution, plate reformatting, plate replication and array printing. Specialized applications include PCR setup, whole genome amplification, high-throughput screening, high-density array printing, cell culture and more. For such specialized applications, the liquid handling systems are often coupled to or integrated into other robotic systems. “We have liquid handling aspects integrated into a few of our microplate readers,” says Joseph Machamer, product manager of Market Development at Molecular Devices (now part of MDS Analytical Technologies). “In some assays there is so little time from when the reagent is added to when the signal is generated that you need to have the plate and the optics in close proximity.”

In cell culture, the liquid handler is often integrated into the microplate handler and washer to facilitate proper dispensing of reagents and washing of cells. “Washers and dispensers to do cell-based assays need to have features and controls that are different and above those that are typically used for biochemical assays,” says David M. Donofrio, director of market development at Molecular Devices. “For cell-based assays the cells have to be kept intact, since the signal intensity is intimately tied to the number of cells in a well.” Hence, the speeds at which reagents are being dispensed and aspirated become very important. There are systems currently on the market designed specifically for use in either cell-based or biochemical assays. These systems have the appropriate software programs that can control and fine-tune such variables as dispensing pressure, aspiration pressure, probe height and position, all of which can affect the integrity of the cell layer. However, having one system that can work well for both types of assays would be ideal and is something that is currently being worked on.

Some other factors to consider when choosing a liquid handling system are the system’s expandability and its ability to operate in an x, y and/or z direction, fixed or disposable tips and their configuration, volume range, individual channel control, layout flexibility, size, and budget. Budget is, of course, one of the biggest considerations, and while the cost of the robotic instrument is certainly important, the cost of consumables for long-term use cannot be overlooked. Most users need to decide up front whether to purchase a liquid handling system that uses fixed or disposable pipette tips. Fixed tips are reused again and again, so while they might seem like the most cost-effective option, they can cause erroneous results due to sample carryover and are expensive when the entire array must be replaced. While carryover is not a concern for disposable tips, which are replaced after each assay or pipetting function, there is the matter of quality, fit, range, availability and price. Hence, when choosing fixed over disposable tips, the types of samples that will be used, the accuracy and precision needed for specific applications, and the length of time the pipettes will be used are all factors that have to be carefully evaluated.

Another factor is the availability of laboratory space. Some liquid-handling workstations are compact enough to be used on a benchtop or inside a laminar hood. Some systems also offer flexibility and multiple configurations for setup and are more efficient in their use of the available workspace. There are also modular and scalable liquid handling systems that can meet the needs of the laboratory now, as well as in the future as user needs increase.

BECKMAN COULTER

BECKMAN COULTER

Biomek Laboratory Automation Workstations are offered in multiple versions—the Biomek NXP, FXP and 3000—that have in common a flexible design and integrated pipetting, dilution, dispensing and integration in a single system. Applications that have been implemented on the various platforms include automated PCR and sequencing reaction setup, cytokine detection, genomic DNA purification from whole blood, human IL-8 assay, plasmid purification, sample preparation and ADME toxicity assays. The Biomek FXP can serve as the central component in a Biomek Assay Workstation—a complete automation system, including labware storage, incubation, plate washing, plate reading and other components.

www.beckmancoulter.com

THERMO FISHER SCIENTIFIC

THERMO FISHER SCIENTIFIC

The liquid handling module for the ArrayScan VTI HCS reader offers synchronous dispense-while-imaging capability combined with kinetic image capture, a range of image analysis algorithms, and “on the fly” processing, which allow real-time capture of cellular phenotypes and rapid biological responses. Multiple aspirate/dispense options enable dye loading, media replacement, incubation and stimulus addition to be fully automated. Integration with the ArrayScan software allows full use of intelligent acQuisition, multiple protocols and automated plate handling. All functions are easy to use, and multiple aspirate, dispensing and mixing options are available from four deck locations for simple and highly flexible experimental setup.

www.thermo.com/cellomics

BIOTEK INSTRUMENTS

BIOTEK INSTRUMENTS

The EL406™ 1536-well Microplate Washer Dispenser offers fast and efficient microplate washing in 1536-well microplates—for even complex washing routines. Accurate and precise dispensing is available from both peristaltic and microprocessor-controlled syringe-drive reagent dispensing technologies. Additionally, the EL406 1536-well Microplate Washer Dispenser is backwards compatible with 96-well and 384-well microplates for increased versatility. All functions are controlled via Liquid Handling Control™ PC software or the instrument’s onboard keypad, and the unit is BioStack™ Microplate Stacker–compatible for high throughput requirements.

www.biotek.com

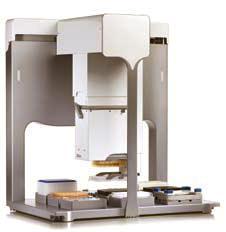

VELOCITY11

The Bravo automated liquid handling platform is a versatile, small-footprint liquid handling system capable of dispensing from 100 nL to 200 μL in 96-, 384- and 1536-well formats or to a column, row or single well of any of these plate types. Its space-saving, nine-plate position footprint can fit inside a standard laminar flow hood, enabling automated liquid handling for cell-based assays or hazardous reagent handling. The deck is easily customized to meet a wide range of assays, with numerous plate pad options. Additionally, the open design of the platform permits access from all sides for simple integration with other devices and unencumbered stand-alone use.

www.velocity11.com

|