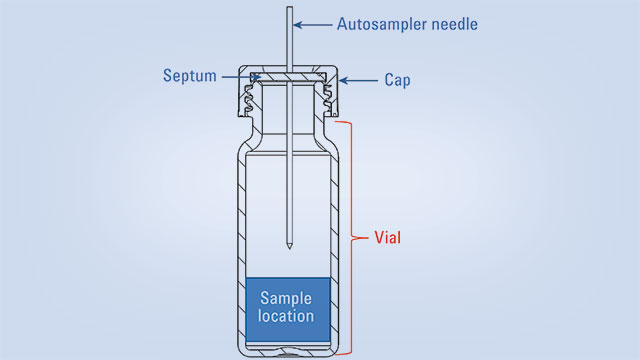

Problem: Vials are small containers composed of glass or plastic used to hold your sample. You place your sample in the vial, and the vial into the autosampler, the instrument takes over, and your sample is on its way to being separated and detected. Vials tend to take a back seat to other components of the analytical workflow, and are often one of the first components to be affected by cost-cutting. Most labs are doing all they can to drive down operational costs. This constant drive to find ways to reduce costs could indirectly cost more in the long term. Switching to a lower cost vial can lead to a range of issues including: vial breakage, leaking samples, improper fit, leaching extractables, and sample loss. These issues reduce lab productivity and more than eliminate any intended cost-savings of the lower cost vial.

Solution: The solution is to ensure you use high quality vials that are appropriate for analytical use across a broad range of analytical applications. Understanding what is involved in the manufacturing of vial glass will help you to better understand why there are so many different types and qualities. For example, what is borosilicate, coefficient of expansion (COE), and Type 1, when it comes to vials.

Boric oxide is common to all silicate glass. Borosilicate glass must contain at least 5 % boric oxide. Boric oxide helps make the glass more tolerant of higher temperatures and corrosion. Next time you order vials, make sure your vials are made from Type 1 borosilicate.

Type 1 glass will provide you with the best overall performance inclusive of lower pH shifts, temperatures above 100°C, and greater resistance to a range of matrices containing water, acids, and most organic substances.

- Type 1 clear borosilicate glass can have a linear coefficient of expansion of 33 or 51.

- Type 1 amber borosilicate glass has a linear coefficient expansion of 51.

- Some budget vial glass has a linear coefficient expansion of 70+.

The coefficient of thermal expansion describes how the size of an object changes with a change in temperature. Specifically, it measures the fractional change in size per degree change in temperature at a constant pressure. There are many COEs including linear, effects of strain, area, and volume. In the case of vial glass, linear COE is the standard metric.

Your samples are valuable so make sure you select vials that provide your sample with a safe environment before injection or long-term storage. Be wary of any supplier offering a substantially lower cost vial, especially if they cannot explain which COE is used in their manufacturing process. Agilent Technologies always maintains high standards, setting tight specifications for the coefficient of expansion of vial glass, and has a comprehensive quality control process to cover all aspects of the product life cycle, providing customers a consistent product each time.

Visit www.agilent.com to learn more.