Colorado State UniversityThe fuel, which is made by mixing unleaded gasoline and oil crushed from oilseed crops, showed only a slight decrease in power when tested on a 2007 John Deere tractor engine at CSU’s Engines and Energy Conversion Laboratory in Fort Collins.

Colorado State UniversityThe fuel, which is made by mixing unleaded gasoline and oil crushed from oilseed crops, showed only a slight decrease in power when tested on a 2007 John Deere tractor engine at CSU’s Engines and Energy Conversion Laboratory in Fort Collins.

A group of farmers who operate The Big Squeeze oilseed processing facility near Rocky Ford mix the blend and pour it directly into their diesel trucks and tractors.

“There was an 8 to 10 percent drop in maximum power,” said Aaron Drenth, a CSU doctoral student who led the most recent testing of the homemade fuel. “That’s not very much — most drivers would never notice it. It’s also consistent with what the farmers who use it have been telling us.”

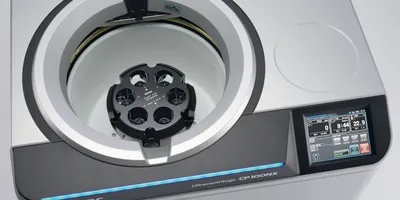

Testing the fuel

Drenth and Daniel B. Olsen, a professor of mechanical engineering at CSU, have spent the past two years testing different versions of the homemade fuel, called TGBs (triglyceride blends), and comparing the performance to biodiesel, renewable petroleum diesel, and traditional diesel fuels.

They swapped out oils made from sunflower, corn, canola, soybean, pennycress, camelina and carinata seeds to make different TGBs. (Jerry J. Johnson, a CSU professor of soil and crop sciences, is leading a parallel study to evaluate how well some of these oilseeds grow in Colorado.)

In addition to performance, Drenth and Olsen also evaluated the TGBs’s emissions, fuel consumption and thermal efficiency. TGBs were comparable to biodiesel, renewable diesel, and diesel in each of those areas; in some cases, they outperformed one of the conventional fuels.

For example, the engine got better “mileage” with TGB than biodiesel.

“We were surprised at how well TGBs did overall,” Olsen said.

Promising results

Olsen and Drenth said the results of the study, which were recently published in the journal Fuel, are promising and that TGB appears to be a viable alternative for farmers. The study is believed to be the first to directly compare engine performance data of these different diesel engine fuels.

“We are not advocating that people go out and start making fuel,” Olsen said. “TGB did very well in our tests but more research is needed to understand its long-term effects on engines and potential safety concerns.”

Olsen and Drenth began studying TGBs after they were approached by Perry Cabot, a research scientist with the Colorado Water Institute and CSU Extension.

Cabot has worked with the farmers who own The Big Squeeze and helped secure Colorado Department of Agriculture grants to add a filtering step to the crushing facility and to test the performance of TGBs at CSU’s Engines and Energy Conversion Laboratory.

“We wanted to see how well this fuel worked and CSU happens to have a lab that will test that,” said Cabot, who also is an author on the study. “It was a natural collaboration between farmers and the university.”

Home-brewed benefits

TGB fuel has many benefits over conventional biodiesels and diesels.

Manufacturing diesel fuel, whether it is petroleum or plant based, is a complex, multi-step process generally completed at expensive processing facilities.

In contrast, TGB fuel is much simpler to make. Farmers crush oilseed crops they grow, filter out the solids and then mix it with unleaded gasoline until it is the consistency of diesel fuel you buy at the pump.

It can be poured directly into conventional diesel engines. Many eco-conscious drivers have powered diesel vehicles on plant oils or leftover French fry grease, but the engines must be modified so they can process the thicker oil

The engine conversion kits cost thousands of dollars to purchase and install.

“When I first heard that the farmers were doing this, I was intrigued,” Olsen. “I had never heard of mixing plant oil with unleaded gasoline to make diesel. So far, it seems to work for these farmers.”

A step forward

Cabot believes the tests run in CSU’s Engines and Energy Conversion Lab are a step toward proving TGB as a viable option for farmers – and potentially the public.

Keeping diesel tractors and trucks fueled isn’t cheap. Farmers use hundreds, if not thousands, of gallons of diesel fuel each year so even a slight price increase can cut into profits.

If farmers can grow oilseed crops on a portion of their land and make their own fuel, they could save a lot of money, Cabot said.

Since Cabot began working with the farmers at The Big Squeeze plant, he has become more than an advocate for TGB fuel.

He now makes his own in his garage to power a 1987 Mercedes-Benz 300D, which he has been driving for over 2 years. He has been able to use oilseeds grown at the CSU Agricultural Experiment Stations for national canola variety trials.

“It works great,” he said. ‘It runs as well as regular diesel and the old engine actually sounds calmer on TGB.”

Colorado State University

Colorado State University