At Popmintchev LABS, Michelangelo and Leonardo da Vinci work cooperatively to stretch the boundaries of existing X-ray science. While Michelangelo focuses on improving existing X-ray technology through the “sculptures” created by 5D imaging, Leonardo uses ultrafast light beams to research and expand the capabilities of X-rays with laser properties.

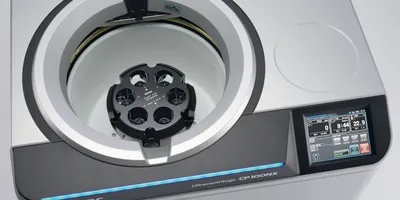

Michelangelo and Leonardo are two “tabletop” laser and X-ray systems located on the University of California, San Diego (UCSD) campus, where Popmintchev LABS is working to revolutionize X-ray science using equipment that is much smaller and less expensive to operate than the massive machinery found in research facilities doing similar work.

Founder and principal investigator Tenio Popmintchev says that his labs are exploring the physics of creating and expanding the capabilities of X-ray laser light with designer classical and quantum properties. He hopes that his team’s research ultimately will lead to advancements in X-ray science for uses such as nano- and bio-imaging and early cancer detection. “We are trying to create light that does not exist in nature,” says Popmintchev, who relocated from the University of Colorado at Boulder to UCSD. “For our research, we need extremely short wavelengths; the peak-to-peak distance is the size of an atom. We measure the duration of our X-ray pulses in attoseconds, which is one billionth of a billionth of a second. For comparison, that is like one second compared with the age of the universe.”

Given the extreme sensitivity of the nature of these X-rays, the challenges of creating a cleanroom space that could meet all environmental isolation requirements was daunting. The fact that the project team was converting an existing lab rather than building from the ground up dramatically increased the degree of difficulty.

Human-centered design strategy

It was a given that the physical constraints of the nearly 2,000-square-foot space in UCSD’s Mayer Hall would present obstacles for the lab design team. Popmintchev’s rigid requirements further complicated this situation, but also helped to unlock many solutions to the design challenges. Taylor Design performed upfront research in collaboration with Popmintchev to better understand his needs for the lab in the near term, as well as to uncover future-use scenarios such as hosting tour groups, meeting with potential donors and mentoring students. Within this framework, the team wanted to ensure that they adequately considered human motivations and behaviors in addition to efficient laboratory operations. In other words, is the “efficiency” built into the design consistent with how the scientists and researchers will actually function in the space?

Taylor Design’s human-centered research methodology resulted in the creation of a 29-page “Design Insights” guide. The guide includes topics such as timing and lab rhythms, which specifically addressed turn-on and turn-off procedures, human activity levels and routines, and environmental and safety isolation of the most sensitive and most dangerous equipment in the labs. Those analyses yielded design directives that included an excess of optical-table space, which is the most expensive real estate for an advanced laser lab, while also maintaining sufficient corridor space for supply carts and moveable experimental setups and diagnostics for “on-the-fly configuration.” The guide also recommended a meeting room outside the clean lab, writable surfaces throughout the space, and “imagery that can instruct, delight, and give a window into laser research.”

The interior design concept for the lab revolves around Popmintchev’s theme of “let there be light,” which is painted above the entry door to the lab. The inherent movement of light waves inspired the idea of creating bands of color “waves” traveling through the space. Some visuals were adapted from an artist’s impression of X-ray laser waves based on an original research of the principal investigator, and which are often used by the Optical Society of America, the National Science Foundation, and laser companies at laser conferences and award announcements.

This concept was translated into an organization system based on the colors of the electromagnetic spectrum, dividing the lab into color-coded workspaces. The team selected cabinetry with glass fronts to ensure that the spectrum of interior colors remain visible, indicating specific groupings and uses. Even when the researchers are wearing protective goggles, the color tone differences are visible.

Though they share the same laboratory space, the two primary lasers in the Popmintchev labs differ in their roles and their requirements. Michelangelo is a relatively traditional machine; Leonardo more demanding of “cleanroom” restrictions and greater flexibility to evolve and adapt. The lasers were assigned different color palettes to clearly delineate their associated workspaces, offering researchers visual cues for where their respective areas begin and end.

Construction challenges and solutions

The parameters established by the research, along with the guidance to “design to empower scientists to do their best research,” eventually gave way to physical construction. And, as often happens when transforming lab space, variations from expected conditions elicited more serious concern than they would in a project with less stringent requirements. For example, an issue with the calibration of temperature sensors that would be of little note for a lab that could tolerate even a one- to two-degree fluctuation prompted the project team to seek a resolution because the Popmintchev lab’s tolerance is within one-half degree of stability.

Cleanrooms, by definition, carry extremely rigid environmental restrictions. The lasers in Popmintchev LABS are particularly sensitive to vibrations, so acoustics need to be managed. The lasers also require low and stable humidity and a relatively stable temperature, though the machines radiate substantial heat. Frequent air cycling that controls the ambient atmosphere and filters out the dust particles to a cleanroom level, which is essential for high-power lasers, has the potential to clash with the equipment’s vibrational and acoustical needs. All of this needs to work in concert, and as a result, design and construction decisions that affected one aspect of the project sometimes triggered the need to alter some other component.

When demolition began, the floor and the ceiling presented immediate impediments. The floor slab required replacement due to cracks and voids, some known and some discovered by scans and during the removal process. One trench was close to six feet deep. Given the sensitivity of the equipment and Popmintchev’s desire for a single-slab subfloor, the team removed and replaced about three times the anticipated 100 square feet of concrete. The alternative of placing equipment over or near such a compromised foundation was a non-starter.

Ceiling depth was another challenge. With the lasers sitting on sturdy tables at a height where researchers could work, and requiring at least 30 inches of clearance to accommodate the lab’s overhead racking system, it was critical that all the components that needed to run through the ceiling be as compact as possible. The team managed to accommodate the ductwork, plumbing, electrical and other conduits in a ceiling that still ended up six to eight inches deeper than planned in the main lab area.

Building information modeling (BIM) was a vital contributor in what became an almost design-build approach. By following three-dimensional computer-aided designs of the building systems in the ceiling space, the project team—comprised of structural engineering firm KPFF, mechanical engineering firm EXP, specialty consultant Vibration Engineering Consultants, and contractor BNBuilders—coordinated sequencing of infrastructure in the ceiling cavity to best optimize the available space.

There was also a design-build feel to the acoustical work. Taylor Design collaborated with the contractor and vibration consultant to ensure that sound from machinery in Popmintchev LABS and its neighboring facilities did not affect the research. They did this without widening the walls and further confining the space. Strategic placement of sound-deadening boards, the use of double-studded walls, and specialty vibrationally isolated laser table legs that are approximately 12 inches in circumference combined to help limit vibration.

Successful conclusion to a complex project

Changes during construction are inevitable—especially when working within existing facilities and designing under such strict requirements. The test is how well a project team meets these challenges with agile, creative solutions. Popmintchev says that in the case of his lab at UCSD, the level of complexity in the finished facility is beyond any he has experienced.

“We filter approximately 250 volumes of air through the lab every hour, which ensures low dust content inside the lab,” says Popmintchev, who also maintains an X-ray laser research lab in Vienna, Austria. “At the same time, we have really low noise, low vibration, the temperature is within half a degree of stability, and the humidity is within two percent of stability. This is something that is very hard to combine. We have seen many labs in the world where they have perfected one or the other parameters, but putting everything together was the challenge.”

Thomas Clark, AIA, is a senior project manager with Taylor Design, a strategy-based design firm with practices in Architectural Design, Interior Design, and Design Strategy. Clark was the project manager on the Popmintchev LABS project for Taylor Design, which has five offices throughout California.

Joe Lowe, AIA, LEED AP, DBIA Assoc., NCARB, an associate and the San Diego office leader for Taylor Design, and Ashley Feichter, NCIDQ, Taylor Design’s lead interior designer on the project, contributed to this article.