Lab operations is a job of countless moving parts. The 6 a.m. message about a broken freezer. The midnight email about missing reagents. The chemical inventory report that’s now overdue. LabOps teams spend their days bridging those critical gaps—keeping scientists on track, keeping environmental, health, and safety (EHS) happy, and still hitting the goals set from administration.

The truth? It isn’t one job, it’s twenty. You’re part scientist, part problem solver, part safety officer, equipment coordinator, procurement specialist, compliance tracker—and yes, firefighter. Every day. All the time.

One of the first questions I ask when I meet someone in LabOps is “How many hats do you wear?” Without fail, they just laugh—or roll their eyes—because the answer is always the same: Too many.

You’re expected to be the glue that binds together scientists, EHS, vendors, facilities, IT, and more—yet no one’s provided you the tools to actually hold it all together. That’s not your fault. That’s the system’s fault.

Too many systems, too little support

Most labs today run on a patchwork of disconnected tools: an app for inspections, a training matrix spreadsheet, a cloud drive for ordering, a digital binder for Safety Data Sheets (SDS), an Excel file for chemical inventory. And yet, everyone’s expected to operate like a high-performance team.

While scientists are focused on discovery and EHS teams are managing risk, LabOps is left translating between systems that were never designed to work together. This fragmented infrastructure doesn’t just waste time, it creates blind spots that lead to duplicated data, missed deadlines, and reactive—not strategic—decision making.

Somewhere along the line, this dysfunction has been normalized. It’s become the status quo. But it doesn’t have to stay that way.

From operational excellence to operational simplicity

In tightly regulated industries like biopharma, we hear the term “operational excellence” all the time, but achieving it often requires complex roadmaps, long timelines, and dedicated transformation teams. For most labs, that’s unrealistic.

At SciSure, we believe there’s a better way forward: operational simplicity. And we’re working toward a platform that delivers it—end to end. Our goal isn’t to add another tool to the pile; it’s to replace the pile with one system built from the ground up for the people who actually use it.

The Scientific Management Platform (SMP) is a novel, integrated system that unites scientists, LabOps, and EHS into one connected system. Forged from a strategic merger between two trusted leaders—eLabNext, known for its electronic lab notebook (ELN) and laboratory information management system (LIMS) software, and SciShield, respected for EHS, biosafety, and chemical safety solutions—we’re working hard to deliver a true home base for the modern lab:

- One login, one interface, and one system that links research, inventory, safety, compliance, and regulatory reporting

- Intuitive dashboards tailored to what scientists, EHS, and LabOps need

- Built-in safety and compliance workflows—no bolt-ons, no “oops, we forgot to do the training”

- A modular design that lets you adopt what you need today and expand when you’re ready

No more logging in and out of ten tools. No cobbling together workarounds just to make your labs function. Just working—confidently, transparently, collaboratively.

CREDIT: SciSure

Beyond LabOps, research managers—who face the same barriers of fragmented data, inconsistent protocols, and limited visibility across experiments—also benefit from a more unified system. When inventory, scheduling, training records, and documentation are all connected, research workflows become easier to manage, share, and scale.

Scientists want to work in their environment. EHS needs reliable data. LabOps needs visibility across both. At SciSure, we’re building a platform that makes that possible—letting everyone do their job well while ensuring they’re connected in the background where it counts.

Shifting LabOps and EHS from reactive to proactive

Permanent “fire-drill” mode leaves no time to optimize and innovate. Running from one task to the next, never quite catching up. There’s no space to think ahead. But when you give LabOps and EHS the right tools, everything changes.

SciSure helps labs shift from reaction to prevention. That means real-time dashboards, automated alerts for compliance deadlines, and role-based views that make it easy to see what’s overdue, what’s at risk, and what’s coming up next.

Tasks like training reminders, inventory updates, and chemical reconciliation shouldn’t require three tools and ten emails. With the right system, they just happen—quietly, reliably, and in the background.

And when that happens, LabOps and EHS leaders gain something rare: time to strategize, to plan, and to lead. Instead of dreading the next audit, you’re ready for it. Instead of catching issues downstream, you’re preventing them upstream. Instead of getting pulled in every direction, you’re setting the direction. With the right data, you now have total confidence walking into the C-suite to ask for the proper resources that your team needs.

Rethinking chemical inventory

Ask any LabOps professional what drains the most time, and chemical inventory will be near the top—not because it’s inherently difficult, but because it’s disconnected.

With SciSure, tasks that once took hours now take minutes. Adding a chemical to your inventory automatically creates a hazard profile utilizing our proprietary database and then adds it to the appropriate reports to ensure regulatory compliance.

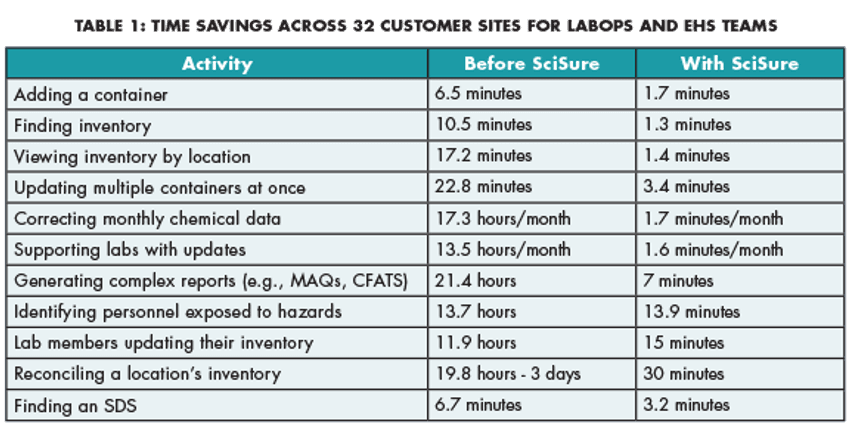

We recently looked at data from 32 customer sites to understand the real impact of transforming chemical inventory workflows. At one customer site, reconciliation time dropped from three days to 30 minutes after implementation. At another, monthly corrections went from 17 hours to under two minutes. When you scale these time savings across dozens of people, across hundreds of tasks, the minutes add up fast.

CREDIT: SciSure

But the real value isn’t just speed, it’s confidence. When inventory connects to hazard profiles, to training requirements, to reporting and procurement, you’re not just checking boxes. You’re running a safer, more accountable lab. And you’re giving scientists and EHS teams shared data they can trust.

A marketplace model for flexibility and growth

No single system will meet every lab’s needs out of the box. That’s why SciSure’s SMP is being designed with modularity and integration in mind.

Let’s say you already have a scheduling tool your scientists love. Great. Don’t throw it away—integrate it. Or maybe your team uses a specific vendor for procurement or equipment monitoring. Perfect—bring them in.

Our Marketplace—an open ecosystem where trusted third parties, including some of our competitors, can plug directly into the SciSure platform—is designed to let labs work however they want. Why? Because we believe that as a scientific community, we are “better together.” Because if it makes your workflow smoother, saves your team time, and helps scientists get back to the work that matters, then we’ll make room. We are serious about interoperability.

As one of our Marketplace Partners put it:

“Our integration with SciSure allows scientists, LabOps, and EHS to view critical data in one seamless place. It means labs can proactively monitor environmental conditions and respond instantly to deviations that could compromise valuable samples.”

— Sridhar Iyengar, founder and chief strategy & technology officer, Elemental Machines

Some customers have even started building their own integrations. One group created a fully custom equipment scheduler inside SciSure using the developer tools. No vendor lock-in. No workarounds. Just functionality that fits the way they operate.

Our vision for the future

Today’s labs are complex, fast-moving, and under increasing pressure to do more with less. LabOps professionals, research managers, and EHS teams all share the same goal: to enable safe, efficient, reproducible science.

SciSure is building a future where they can do just that—from a single flexible, scalable, connected platform. Our vision is simple: Give labs the tools to focus on what matters. Eliminate the noise, reduce the admin, and empower the people behind the science.

Because when systems work for you, science moves faster.