Improve Consistency by Getting the Essentials Right

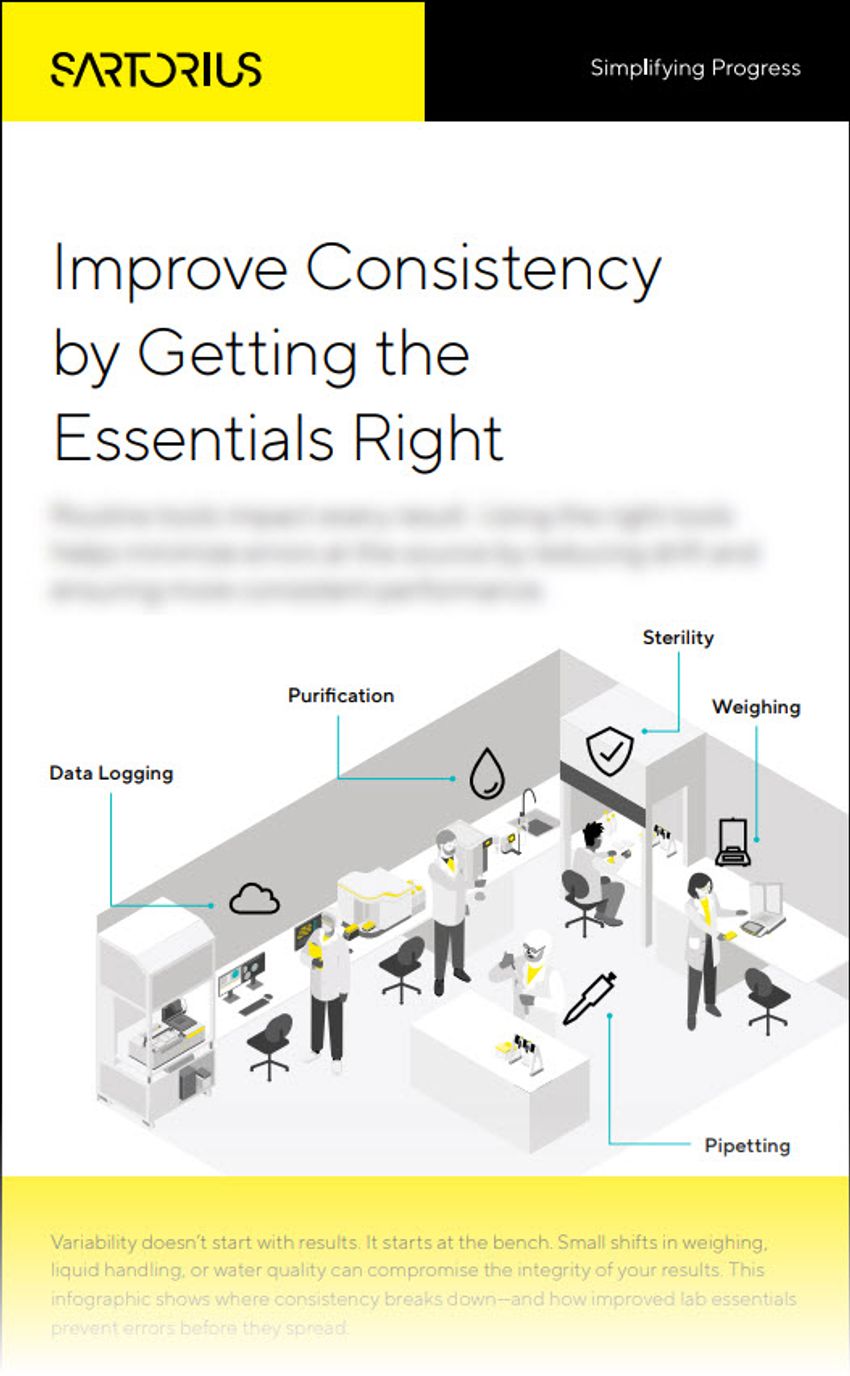

Routine tools impact every result. Using the right tools helps minimize errors at the source by reducing drift and ensuring more consistent performance.

Variability doesn’t start with results. It starts at the bench. Small shifts in weighing, liquid handling, or water quality can compromise the integrity of your results. This infographic shows where consistency breaks down—and how improved lab essentials prevent errors before they spread.

What’s Changed in Precision Weighing

▪ Weighing is often the first data point in a workflow. Static, air pressure, or transcription errors can skew results and compromise everything downstream.

▪ Advanced lab balances such as Cubis® II Ultra-High Resolution are built to stop drift at the source— stabilizing in seconds after a 100 mbar pressure shift.

The Cubis® II MCA225S achieved a 14% lower minimum sample weight than a leading competitor, verified under USP 41 standards.

Consistent Pipetting in Three Steps

Aspirate: Piston movement, tip immersion depth, and pipetting cadence vary by user. Small shifts in technique raise CVs and can cause repeat work. Picus® 2 electronic pipettes reduce user variance with controlled aspiration.

Dispense: Uneven release and skipped wells cause variance in results. Electronic protocols track each dispense in plates and tubes helping the user.

Repeat: Strain builds across plates. Ergonomic design and light tip ejection reduce fatigue and support consistent technique over time.

Apps help build consistency too. Picus® 2 works with the Sartorius Pipetting App to track workflow steps and reduce user variation.

What Clean Water Really Requires

Application testing confirms that Arium® Pro VF meets or exceeds ASTM Type I standards and reduces traces of elements, PFAS, DNase/RNase, and endotoxins to below detectable levels.

Purify – Ion exchange resin, UV lamp, and ultrafilter eliminates all kind of contaminations.

Dispense – Controlled flow with different dispensing option ensures accuracy at the point of use

Security – Final filter with a double layer 0.2/0.45 µm membrane removes particles, sterilizes the water and protects the system from any secondary contamination

▪ Ultrapure water is essential to blank samples, dilutions, and standard preparation. Even small impurities can distort results.

▪ Arium® Pro VF meets the purity demands of life science and analytical labs.

When Filters Clog, Performance Drifts

Tangential flow keeps ultrafilters running smoothly. By directing liquid across the membrane surface, fouling is reduced and sample integrity is protected.

Tangential flow is available in Vivaspin® 500, Vivaspin® Turbo 15, Vivaflow® TFFCassette, and more, covering sample volumes from 0.1 mL to 5 L using the same high-performance ultrafiltration membranes.

Microbial Control by Design

Sample Handling

Touch-free membrane transfer eliminating contamination

Closed-loop sampling with integrated septum port

Detection Speed

Detect mycoplasma, bacteria, and fungi in under 3 hours.

8 hours continuous air monitoring with gelatin filters

Aseptic environments require more than sterility: they require tools that work with, not against, cleanroom protocols. Our QC solutions are designed for controlled spaces, speed, and minimizing operator intervention and secondary contamination at every step.

Put Traceability on the Bench

Handwritten records introduce avoidable risk—studies suggest 1 to 3 percent of entries are lost or altered during manual transfer.

▪ Digital logging reduces that risk. Instruments capture user ID, method version, timestamp, and checksum to create an audit-ready record under 21 CFR Part 11and Annex 11.

▪ Systems such as Cubis® II and Picus® 2 log data in linked formats to support traceability across steps.

Want to build lab consistency into your workflow? Explore Sartorius Lab Essentials sartorius.com/lab-essentials