Pharmaceutical laboratories operate under relentless pressure to ensure precision, efficiency, and compliance. With increasing workloads, stringent regulatory demands, and the need for rapid results, lab managers and technicians face growing obstacles. These pressures underscore the urgent need for advanced technologies that streamline workflows, reduce errors, and optimize overall productivity. By automating key processes and integrating data management, these tools enable labs to meet the rigorous demands of drug testing and quality control with greater efficiency and confidence. Through a hypothetical case study, this article illustrates the common challenges faced by labs worldwide and demonstrates how implementing an advanced liquid chromatography (LC) system can improve daily workflows and overcome persistent inefficiencies.

This article explores how a fictional pharmaceutical lab implemented an advanced LC system to improve their daily workflows and overcome persistent inefficiencies.

The daily challenges of the pharmaceutical space

Credit: Agilent

Ethan, a pharmaceutical lab technician, starts his day by handling a high-volume sample transfer for potency and impurity testing. Each vial represents critical data essential to ensuring that drugs meet safety and efficacy standards. The task is painstakingly meticulous. Every sample must be labeled accurately, placed in the correct tray position, and handled with care to avoid contamination. Any misstep—a mislabeled vial, a misplacement, or a minor procedural error—could invalidate the results. These mistakes not only waste hours of work and expensive materials but also risk delaying crucial drug approvals.

For lab managers like Dr. Wilson, overseeing these processes involves a different but equally challenging set of responsibilities. Dr. Wilson must ensure that all operations meet good manufacturing practice (GMP) requirements while keeping tight schedules on track. Errors can lead to costly retesting, compliance failures, and setbacks in the supply chain. The current manual workflows, while functional, are increasingly unsustainable. For Ethan and Dr. Wilson, it is clear that their lab needs a more efficient and reliable system to keep pace with industry demands.

Introducing advanced LC technology and software solutions

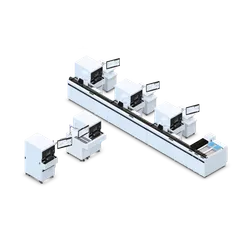

Dr. Wilsons’s search for solutions led the lab to adopt Agilent’s 1260 Infinity III LC system with the infinity III Multisampler and Advanced Sample Linking software. As Ethan reviewed the new system with his team, he was immediately drawn to its automated sample handling features. Unlike the manual processes that dominated his previous workflow, the new system’s dual-needle injection setup could process up to 6,144 samples in a single sequence. Ethan realized this automation could eliminate the repetitive manual handling that often caused delays and mistakes.

Credit: Agilent

During a busy testing day, Ethan ran his first batch using the new setup. The Agilent InfinityLab Sample ID Reader automatically scanned pre-barcoded vials, confirming their identity and placement within the tray. Ethan was impressed by how this eliminated the tedious task of arranging vials in exact positions—a process that previously consumed hours. Now, he simply loaded the tray, and the system verified the placement automatically, ensuring error-free operation and saving valuable time.

For Dr. Wilson, the system’s integration with their laboratory information management system (LIMS) was equally noteworthy. She watched as the Agilent Advanced Sample Linking software seamlessly integrated with the lab’s digital infrastructure. From sample registration to final reports, every movement was digitally tracked. This gave Dr. Wilson confidence that compliance with GMP requirements was no longer a manual burden but an assured, automated process. The ability to handle growing sample volumes without risking errors or delays became a tangible reality for her team.

Meeting the demand for traceability and compliance

One of the lab’s pivotal moments came when Ethan used the new system during a high-priority project. The workflow began with the LIMS registering the samples and sending the necessary data to the Sample Scheduler. Barcodes on the vials linked the physical samples to their digital records, ensuring flawless traceability. Ethan no longer needed to worry about mislabeling or misplaced samples—every detail was automatically recorded and verified.

Dr. Wilson noticed another critical improvement: fewer disruptions in daily operations. During a previous project, running out of solvents mid-sequence had derailed their workflow. Now, with Agilent InfinityLab Level Sensing technology monitoring solvent levels, Ethan received real-time alerts before supplies ran low. This proactive feature allowed her to replenish the system without interrupting analysis, ensuring consistency and minimizing downtime.

Minimizing downtime and ensuring consistency

Credit: Agilent

The implementation of Agilent InfinityLab Assist Hub brought further clarity to the lab’s operations. Ethan’s daily tasks now included guided instructions for running complex methods and real-time updates on system performance. This centralized management reduced variability in workflows and improved data reliability. Ethan appreciated how the software empowered him to focus on interpreting results and solving problems, rather than troubleshooting process errors.

For Dr. Wilson, the benefits of these enhancements extended beyond operational efficiency. She could now allocate resources more effectively, reduce the need for retests, and confidently report on the lab’s productivity improvements to stakeholders. The combination of speed, precision, and regulatory compliance provided a competitive edge that positioned the lab as a leader in the industry.

The impact of an efficient new workflow

The adoption of Agilent’s 1260 Infinity III LC system with the Infinity III Multisampler and Advanced Sample Linking software revolutionized the lab’s operations. Tasks that once consumed Ethan’s day, like manually arranging and verifying samples, became streamlined. The lab’s ability to handle high sample volumes without sacrificing accuracy ensured that Ethan could focus on meaningful scientific work—a shift that reinvigorated his passion for the job.

By reducing errors and bottlenecks, Dr. Wilson could ensure that projects stayed on schedule while maintaining the high standards demanded by regulators. With fewer setbacks and greater reliability, the lab’s output improved, creating a ripple effect that benefited the entire supply chain.

The future of pharmaceutical testing

As pharmaceutical labs face increasing demands for speed and accuracy, the limitations of manual workflows have become more apparent. Automation, smart sensing, and integrated data management are essential for staying competitive in today’s market. Agilent’s 1260 Infinity III LC system with the Infinity III Multisampler and Advanced Sample Linking workflow offers lab managers and technicians the tools they need to thrive in a fast-paced, high-stakes environment.

By embracing these advanced solutions, pharmaceutical labs can maximize precision, streamline their operations, and meet regulatory expectations with ease. With Agilent’s technology, the challenges of today become opportunities for tomorrow, enabling labs to deliver safer, more effective products to market faster and with greater confidence.

Learn more about the entire Agilent Infinity III LC Series portfolio and Agilent Advanced Sample Linking software.