Regular equipment maintenance is crucial in any industry, but in laboratories it carries even greater weight. With experiments often involving hazardous substances or powerful chemical reactions, the failure or malfunction of tools, equipment, or furniture can put researchers at serious risk.

Fume hoods play a central role in lab safety. Designed to capture and eliminate gases or vapors released during experiments, they protect both the environment and the people working inside the lab. Consistent upkeep is essential to ensure fume hoods perform at their best. Yet many lab managers still find themselves scrambling when it comes to scheduling maintenance—or underestimating its value altogether.

With more than 20 years of experience supporting laboratories worldwide, Louis Paiva, senior systems engineer at WNA Labs, has seen firsthand what happens when maintenance falls by the wayside. The issues are wide-ranging: broken furniture, rust, corrosion, damaged tools, improper ventilation, storage doors that don’t seal properly—all of which create risks for users.

“Lab teams often underestimate the importance of regular maintenance to keep things running safe and smoothly,” Paiva explains. “Safety is obviously the main focus of maintenance programs, but it’s not the only concern. Labs—and fume hoods, in particular—consume a significant amount of energy. Ensuring that these run at high efficiency doesn’t just save money, it also reduces waste and promotes sustainability.”

In other words, maintenance is about more than fixing what’s broken. It is about ensuring energy efficiency, protecting budgets, and minimizing a lab’s environmental footprint. A poorly maintained fume hood, for instance, might consume significantly more energy than necessary, driving up costs and creating unnecessary environmental impact.

Knowledgeable staff, smarter practices

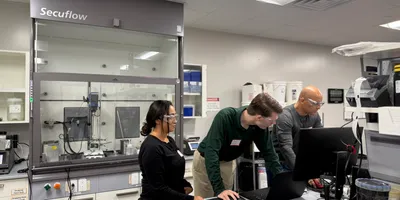

Paiva argues that maintenance alone is not enough. True lab efficiency also depends on training staff to understand and properly use the tools at their disposal. To meet these demands, manufacturers and suppliers should ideally provide ongoing support to customers, ensuring that new team members are adequately trained and familiarized with best practices.

“On many of our visits, we encounter lab staff who don’t fully understand how to use furniture or equipment properly—for example, which cabinets are suited to which substances, or where hazardous materials should be stored,” Paiva says. “We’ve also seen cases where special safety features on fume hoods are ignored simply because staff didn’t know they existed or why they mattered. This kind of oversight doesn’t just increase costs and waste energy; it creates real safety risks.”

Paiva emphasizes that fostering a culture of safety and efficiency is as important as providing annual maintenance alone. This means combining technical upkeep with knowledge-sharing, empowering staff to flag potential issues in their daily work and replace old habits with safer, more efficient ones. When users know how a fume hood should function, he says, it becomes much easier to spot failures and fix problems before they escalate.

“Sometimes people get used to manually closing a sash that was meant to be automated, without realizing that, beyond convenience, automation improves energy efficiency. We also remind customers never to ignore unusual noises or vibrations, or disable sensors and alarms—even if they seem to trigger too often—because when a real problem occurs, you won’t know it. Instead, teams should understand why an alarm is going off and get the root cause addressed.”

He adds that while rust and corrosion may not demand urgent attention, they should not be ignored. In labs that handle corrosive chemicals, addressing them early can prevent bigger problems down the line. Unusual noises or

For Paiva, lab maintenance should not be viewed as an occasional task, but rather as a continuous commitment to personnel safety, the success of experiments, and the sustainability of operations.

“By aligning proper maintenance with training and awareness, laboratories can create safer environments, cut costs, and contribute to a more responsible future for science,” he says.