Matlantis has launched Matlantis CSP, a new crystal structure prediction capability designed to rapidly identify previously unknown stable crystal structures at research scale. The tool shifts computational screening earlier in materials discovery workflows, enabling laboratories to eliminate physically implausible candidates before committing to costly, time-intensive synthesis experiments.

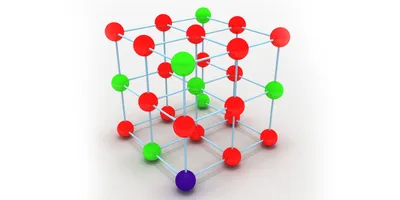

Crystal structure prediction is the computational method that determines stable atomic arrangements from elemental composition alone. Within computational materials research, crystal structure prediction helps laboratories narrow candidate materials before experimental validation. As materials discovery programs face increasing pressure to shorten development timelines and reduce experimental waste, crystal structure prediction has become a critical decision-support tool rather than a niche modeling exercise.

Why crystal structure prediction has been difficult to scale

Many laboratories have struggled to integrate crystal structure prediction into routine materials discovery because conventional approaches rely heavily on density functional theory. While accurate, density functional theory evaluations often require hours per structure, limiting throughput and restricting the size of searchable composition spaces.

Additional constraints have historically included:

- Bias toward specific compositions when exploring variable systems

- High computational cost for large-scale searches

- Fragile workflows that fail when nonphysical atomic configurations arise

These limitations have confined crystal structure prediction to specialized teams and prevented broader adoption across computational materials research groups.

How Matlantis CSP supports computational materials research at scale

Matlantis CSP combines machine-learning-driven simulation with proprietary search algorithms to make crystal structure prediction practical at operational research scale. The capability builds on Matlantis’ universal atomistic simulator and its Preferred Potential (PFP), a machine-learning interatomic potential designed to efficiently model diverse material systems.

High-throughput crystal structure prediction

Using PFP, Matlantis CSP evaluates structural energies in seconds to minutes rather than hours. Built-in safeguards allow searches to continue even when anomalous atomic configurations appear, enabling uninterrupted high-throughput crystal structure prediction across large datasets.

Efficient exploration of composition space

Matlantis CSP uses a proprietary algorithm to explore full composition spaces while preserving diversity among sampled structures. Compared with random search approaches, this method improves search efficiency by approximately three to six times, supporting more comprehensive materials discovery without systematic omissions.

Parallel execution without complex setup

The platform optimizes memory use and parallel processing specifically for the Matlantis environment. Laboratories can initiate large-scale crystal structure prediction runs without complex environment configuration or specialized infrastructure, lowering operational barriers for computational materials research teams.

Early adoption in applied materials discovery

Honda R&D is adopting Matlantis CSP to improve exploration efficiency in materials discovery, including multi-component systems and metastable structures that have historically been difficult to evaluate due to computational cost.

“We have high expectations for CSP as a technology that will dramatically improve exploration efficiency in materials development,” said Mitsumoto Kawai, chief engineer, device process, innovative research excellence, Honda R&D Co., Ltd. “Through CSP, crystal structure searches—including multi-component systems and metastable structures that were previously impractical—have become feasible.”

According to Matlantis, early crystal structure prediction runs across oxides, alloys, and phosphides have identified more than 10 previously unknown stable crystals. In a gallium–gold–calcium system, the software identified 13 new crystal structures, substantially updating the phase diagram relative to existing databases.

What crystal structure prediction means for lab managers

For lab managers overseeing materials discovery programs, scalable crystal structure prediction changes how teams allocate experimental effort. By narrowing candidate structures computationally, laboratories can reduce the number of low-probability synthesis experiments and better align computational materials research with experimental validation.

Operational impacts include:

- Shorter development timelines

- Reduced experimental cost and reagent use

- More efficient use of instrumentation

- Greater feasibility of exploring complex material systems

“With Matlantis CSP, we’re making crystal structure prediction practical at real research scale,” said Daisuke Okanohara, CEO, Matlantis. “Teams can explore broader composition spaces, identify promising candidates earlier, and reduce time spent on low-probability experiments.”

As computational materials research continues to move upstream in laboratory workflows, crystal structure prediction tools like Matlantis CSP are positioned to become standard infrastructure for materials discovery programs focused on energy transition, decarbonization, and advanced manufacturing.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.