In the fast-paced environment of the modern laboratory, the trade-off between speed and precision has historically been a painful compromise. Traditional wet chemistry methods offer accuracy but at the cost of time, hazardous waste generation, and sample destruction. Vibrational spectroscopy—specifically Fourier Transform Infrared (FTIR) and Near-Infrared (NIR)—has fundamentally disrupted this paradigm. By harnessing the interaction of light with molecular bonds, these technologies allow laboratories to obtain complex chemical data in seconds, often with little to no sample preparation.

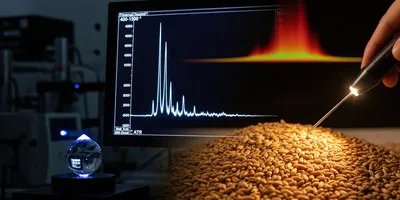

For the Laboratory Manager, integrating these tools is not just a technical upgrade; it is a strategic operational shift. These instruments serve as the "eyes" of the facility, providing critical data that impacts supply chain velocity and regulatory compliance. Whether you are identifying a suspicious white powder in a forensics lab, verifying the protein content of incoming wheat tonnage, or releasing a batch of pharmaceutical tablets for sale, infrared tools are the first line of defense. However, because they both sit under the umbrella of "molecular spectroscopy," a common purchasing pitfall is treating them as interchangeable. While they both measure molecular vibrations, they solve fundamentally different business problems and require vastly different support structures.

The Core Distinction: Fingerprint vs. Workhorse

To maximize Return on Investment (ROI) and avoid costly procurement errors, laboratory staff must understand exactly where each part of the infrared spectrum excels. This is not merely an academic distinction between wavelengths; it is a functional distinction between "identifying the unknown" and "quantifying the known." Selecting the wrong tool can lead to a $50,000 instrument sitting unused because it cannot penetrate the sample container, or conversely, an instrument that generates data too complex for the quality assurance team to interpret routinely.

FTIR: The Chemical Fingerprint (Mid-IR)

FTIR operates in the Mid-Infrared region (4000–400 cm⁻¹). It excites "fundamental" molecular vibrations.

- The Superpower: Specificity. FTIR produces a unique spectral "fingerprint" that can positively identify virtually any organic compound (and many inorganics).

- The Limitation: It usually requires sample contact (ATR crystal) or preparation (KBr pellets). It is difficult to look "through" packaging.

- Best For: R&D, Failure Analysis, Contaminant Identification, Microplastics, and Chemical Identity Verification (ID Testing).

NIR: The Quantitative Engine (Near-IR)

NIR operates in the Near-Infrared region (12,500–4000 cm⁻¹). It measures "overtones" and combinations of vibrations.

- The Superpower: Penetration power. NIR light can pass through glass vials, plastic bags, and deep into powders. It is the ultimate "no-prep" technique.

- The Limitation: The spectra are broad and featureless to the human eye. They require chemometrics (statistical modeling) to interpret. You cannot simply "look up" a library match as easily as with FTIR.

- Best For: Routine QA/QC, Moisture/Protein/Fat analysis, Uniformity of Content, and Inline Process Monitoring.

FTIR Applications: Purity and Forensics

In regulated industries like pharmaceuticals and forensics, the "burden of proof" is absolute. You cannot assume a raw material is correct simply because the label says so. FTIR provides the definitive, legally defensible identification required to ensure purity and safety before a product ever enters the manufacturing stream.

- Pharma Raw Material ID: Under USP <197>, every drum of incoming active ingredient must be identified. Handheld FTIR devices allow warehouse staff to verify identity without opening the drum, preventing cross-contamination.

- Microplastics: As environmental regulations tighten, FTIR microscopy (and the newer QCL-IR) is the gold standard for counting and identifying polymer particles in water and bottled beverages.

- Failure Analysis: When a customer complains about a "black speck" in a clear plastic film, FTIR microscopy can identify the speck as charred rubber or oxidized polymer, pinpointing the root cause in the extruder.

NIR Applications: Speed and Efficiency

NIR is less about "what is this?" and more about "how much is in this?" In sectors operating on thin margins, such as agriculture and bulk chemical manufacturing, the ability to obtain a quantitative result in real-time transforms the lab from a bottleneck into a process control asset.

- Agriculture & Food: NIR is the backbone of the global grain trade. In 30 seconds, it quantifies moisture, protein, and oil in wheat or soy without chemicals. This data dictates the price of the commodity.

- Pharmaceutical Blending: "Blend Uniformity" is critical. Wireless NIR probes can be inserted directly into a tumble blender to monitor the mixing process in real-time, telling operators exactly when the active ingredient is perfectly distributed.

- Moisture Analysis: Unlike Karl Fischer titration (which uses toxic reagents), NIR measures water content non-destructively. This is crucial for freeze-dried products where the vial seal cannot be broken.

Manager's Memo: The Hidden Costs of Calibration

The Total Cost of Ownership (TCO) differs wildly between the two technologies, and the purchase price is often the least significant factor. The true cost lies in the "data labor"—the amount of time your scientists must spend building, maintaining, and validating the libraries or models that drive the instrument.

- FTIR is "Day One" Ready: You can buy an FTIR and start identifying chemicals immediately using commercial libraries (e.g., NIST, Wiley). The maintenance is low, typically involving desiccant changes and source replacement every few years.

- NIR is a "Project": NIR requires a "Calibration Model." You must scan hundreds of samples and reference them against a primary method (like HPLC or Oven Drying) to teach the instrument what "12% moisture" looks like.

- The Takeaway: Do not buy an NIR unless you have the staff or vendor support to build and maintain these models. An uncalibrated NIR is essentially an expensive paperweight.

Purchasing Guide: What to Look For

When evaluating new FTIR or NIR instrumentation, look beyond the shiny brochure specs. You need to assess how the hardware will survive in your specific environment—whether that is a pristine R&D bench or a dusty loading dock—and how the software handles the complexity of your samples.

Feature | FTIR Consideration | NIR Consideration |

|---|---|---|

Sampling Interface | Diamond ATR: Essential for durability. Zinc Selenide (ZnSe) is cheaper but scratches easily and cannot handle pH extremes. | Integrating Sphere: The standard for heterogeneous powders. Transmission: Better for clear liquids or tablets. |

Detector Cooling | DTGS (Room Temp): Good for routine use. MCT (Liquid N2): Required for high-speed kinetics or microscopy. | InGaAs: Standard. ensure it is temperature-stabilized for consistent results. |

Portability | Handhelds are great for incoming goods (loading dock). | Handhelds are available but check battery life and model transferability. |

Software | Look for "Multi-component Search" to identify mixtures. | Look for easy "Model Transfer" tools if you plan to buy multiple units. |

Conclusion: The Spectrum of Success

Ultimately, the choice between FTIR and NIR is not binary; it is situational. Many modern laboratories find that the most robust quality control strategy involves a handshake between the two. FTIR acts as the gatekeeper, ensuring the identity and purity of raw materials upon arrival, while NIR serves as the process watchdog, monitoring blending, drying, and final product uniformity in real-time. By understanding the distinct "personality" of each infrared region—FTIR’s specific fingerprinting versus NIR’s rapid penetration—lab managers can deploy capital more effectively, reducing bottlenecks and ensuring that data quality scales with production volume.