Automated sample storage has quietly become a significant upgrade for many labs. As research organizations collect ever-larger volumes of samples, traditional cold storage methods—rows of freezers and manual tracking spreadsheets—are not sustainable for many organizations.

To understand how automation is reshaping this part of lab operations, Lab Manager spoke with Scott Reeves, director of technical sales engineering, and Kathi Shea, chief client solutions officer at Azenta, a provider of automated sample management systems. Reeves and Shea explained how automation enhances sample integrity and optimizes space, as well as what lab managers should consider when buying.

The benefits of automated sample storage

The first and most immediate benefit is space efficiency. Automated systems consolidate what might otherwise be dozens of manual freezers into a smaller footprint, often by building upward rather than outward. In laboratories, every square foot is valuable—that vertical density matters. Reeves notes that “in a traditional unit you have about five feet of storage height, but most ceilings are 10 feet—we’re wasting half the room.”

Beyond space savings, automation safeguards sample integrity by minimizing human handling. Each retrieval in a manual freezer introduces the potential for temperature fluctuation, cross-contamination, or labeling errors. Automation standardizes these processes and improves reproducibility across experiments. As Shea explains, when humans are involved, “error-proofing becomes harder,” but automation “reduces that pre-analytical variability.”

Automated systems also enhance data traceability. Every access is logged, creating a full audit trail for regulated environments such as biobanks, pharmaceutical R&D, and clinical labs. That visibility turns what was once a disjointed process into a verifiable, digital record of every interaction.

Types of automated systems

Automated storage isn’t limited to ultra-cold temperatures. Systems now span from controlled ambient to liquid nitrogen environments at –190 °C, offering flexibility for nearly any sample type, according to Reeves.

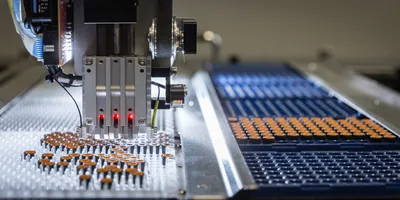

The form factors are just as varied. Labs can choose between modular systems that fit beside workbenches or large-scale centralized installations capable of managing thousands of samples. Reeves and Shea note that automated systems are now found in some freezer farms and biobanks as well.

Automated sample storage was initially used for compound management, according to Reeves, “but it’s growing in lower-temperature biologics and cell-based work.” Ultimately, the benefits of automated sample storage apply across labs and industries.

What to consider before buying

Adopting automation requires more than just purchasing new hardware. Labs should start by standardizing their consumables and labware to ensure compatibility with robotic systems. Shea notes that “it’s hard to get everyone on the same consumable page, but that’s how you get the most benefit.”

Next, labs should evaluate whether they’ve reached an inflection point where manual storage becomes unsustainable. A clear signal is when labor costs rise from constant sample retrieval or when space runs out in decentralized freezer farms. As Reeves puts it, “as access levels increase, your labor needs start outstripping what you can do manually.”

Maintenance costs should also be factored in. Compared directly, automated sample systems may have more maintenance requirements—the robotics need to be maintained as well as the refrigeration system. But a single automated system can replace multiple manual freezers thanks to its storage density. Overall, there is a net decrease in preventative maintenance. As Reeves puts it, “You’re maintaining one system instead of 40.”

Finally, labs should take time to gather organization-wide input. Automation works best when it serves every stakeholder, not just a single department. Lab technicians, lab managers, QA teams, and other departments will all have different priorities related to inventory management, so finding the intersection of those priorities is where the optimal product may lie.

Reeves recommends a structured, data-driven approach: spend time to understand what the lab already has and collect the information needed to “cover the full breadth of what your organization could need.”

The bottom line

Automated sample storage is a cornerstone of lab modernization. By consolidating equipment, logging every transaction, and preserving sample integrity, automation gives lab managers control and visibility that manual systems simply can’t match.

For facilities planning their next phase of digital transformation, automated storage offers a clear path toward more efficient, compliant, and data-driven operations—one where every sample, and every square foot, counts.

- This article was created with the assistance of generative AI and has undergone editorial review before publishing.