Once when helping a friend do the dinner dishes, she said, “You wash them so thoroughly.” I laughed and said, “I wash dishes like lab glassware.”And why? Because I was the ‘lab washer’ more than once during my science education. Now, modern machines handle that task.

For today’s lab washers, in general, “Scientists look for under-the-counter lab washers that have added features that make life a little easier and offer green capabilities,” says Odette Nolan, product specialist at LABCONCO (Kansas City, MO).

Those features include sustainability. For example, Deborah Ruriani, manager of marketing communications at Miele Professional (Princeton, NJ), says several factors contribute to machine longevity, such as fast cycle times, heating rates, and product construction. “Our glassware washers are tested to perform 15,000 operating hours and 90 percent of the machine is recyclable, constructed of high-grade stainless steel with plastic components clearly marked to facilitate recycling.” Ruriani says. “Baskets and inserts also need to be made of high-grade material and should be interchangeable.” She adds, “Sustainability is not just about saving energy and water, but also about making sure that a lab washer does not end up in a landfill.”

Advanced options

Many advances in today’s lab washers involve special features. For instance, lab washers include capabilities to wash specific pieces of glassware. “In a pipette washer,” Nolan says, “an attachment forces water through the pipettes and then forces air through to dry them, so you don’t need an oven later.” The air, though, only dries the glassware. It doesn’t sterilize it. For that, researchers still need an autoclave.

In some lab washers a rack includes spindles for glassware with long necks, such as volumetric flasks. These features wash and dry, by forcing water and air through the spindle, respectively. “This cuts down the handling time of the glassware, and anytime you handle glassware, your odds of breaking it go up,” says Nolan.

Manufacturers are looking to be solutions providers rather than just sell products. For example, there are labs that have high volumes of glassware to wash. If space allows, a user can buy a larger capacity glassware washer or two under counters. Likewise, says Ruriani: “A user can get twice the washing capacity in the same footprint with our

stackable machines.”

Efficient cleaning

To make glassware washing efficient, machines must use fewer resources. “Green is always on the mind of everybody,” Nolan says. To make a lab washer more resource efficient, manufacturers take several approaches. For instance, a washer’s controls can include the ability for delayed washing, just like a home dishwasher. This lets users run the machine at off-peak hours, when electricity costs less.

The efficiency also depends on the speed of washing. For instance, Ruriani points out that powerful heating elements get water up to temperature quickly and powerful circulation pumps require less water per fill to provide a rigorous but gentle wash. These features reduce the overall wash time.

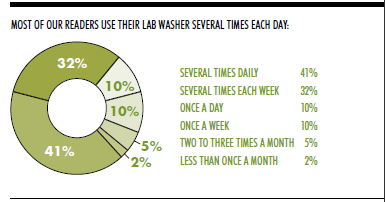

When it comes to water, the value of savings comes from how often a lab runs its washer. “It depends on the lab,” Nolan says. “We had a call from someone who was running a washer four times a day for BOD [biochemical oxygen demand] bottles, and a lab washer can take one and a half to two hours per cycle.” In such a situation, going from an older lab washer that uses 20 gallons per cycle to one that uses just 13 can save considerable water—140 gallons a week in the case of the BOD bottle washer.

From the field

The benefits of a lab washer arise largely from how it gets used. For example, Monica Zatarski, PharmD, of MD Custom Rx (Brookfield, WI), says, “We use our lab washer to wash laboratory equipment and glassware used in prescription compounding.” Typically, that use results in running the lab washer once—sometimes twice—a day Monday through Friday. When asked what features she likes most about her lab washer, Zatarski says, “Primarily, I like the fact that we installed it to be able to provide a rinse cycle with purified water, which allows us to be USP [United States Pharmacopeia] compliant without relying on my staff to rinse everything.” She adds, “It gives great peace of mind knowing that the washer is able to steam clean and cleanse our equipment [at a level] unsurpassed by manual or residential dishwashing.”

The benefits of a lab washer arise largely from how it gets used. For example, Monica Zatarski, PharmD, of MD Custom Rx (Brookfield, WI), says, “We use our lab washer to wash laboratory equipment and glassware used in prescription compounding.” Typically, that use results in running the lab washer once—sometimes twice—a day Monday through Friday. When asked what features she likes most about her lab washer, Zatarski says, “Primarily, I like the fact that we installed it to be able to provide a rinse cycle with purified water, which allows us to be USP [United States Pharmacopeia] compliant without relying on my staff to rinse everything.” She adds, “It gives great peace of mind knowing that the washer is able to steam clean and cleanse our equipment [at a level] unsurpassed by manual or residential dishwashing.”

The features needed in a lab washer depend on budget and usage. As Ruriani says, “You have to really understand what someone is washing in the lab and their requirements [in order] to match them to the right system.” For example, she says, “People performing drug compounding tend to have confined budgets so they are limited in what they can spend, but they want a good washer that will last.”

High-end options

In cases where a researcher needs to validate cleaning, such as in a pharmaceutical environment, even more features can come in handy. For example, some users require secure controls and cycle documentation, fail-safe cycles and program monitoring, as well as validation documentation and execution. “This requires programmability,” says Ruriani. “Delivering repeatable wash results requires superior technologies, such as sensors on rotating spray arms that alert the user of a problem with the wash cycle, for example, if glassware is blocking an arm.” This allows the user to stop the process and rerun the wash.”

Some lab washers also provide maintenance-free conductivity monitoring that keeps track of the cleanliness of the rinse water leaving the washer. Likewise, some lab washers include HEPA filtered forced-air drying.

To get reliable cleaning, even seasoned and thorough hand washing of glassware fails. It takes an automated lab washer—one with modern capabilities.

For additional resources on Lab Washers, including useful articles and a list of manufacturers, visit www.labmanager.com/lab-washers