In an era of increasing environmental consciousness, the scientific community is scrutinizing every facet of its operations to reduce its ecological footprint. While energy consumption and waste management have long been areas of focus, a critical and often overlooked aspect is the environmental impact of the materials used daily in research and diagnostics. The true cost of a material extends far beyond its purchase price, encompassing its entire journey from extraction to disposal. This comprehensive view is the core of life cycle assessment (LCA), a powerful methodology for quantifying the complete environmental burden of a product, process, or service.

The application of LCA to laboratory materials is a pivotal step toward building a more sustainable and responsible scientific enterprise. Rather than relying on assumptions or partial data, a robust LCA provides an evidence-based framework for identifying environmental hotspots, making informed purchasing decisions, and implementing targeted strategies for minimizing a laboratory's carbon footprint. It offers a structured way to understand the complex, interconnected web of resource consumption and emissions associated with every pipette, flask, and reagent. The following analysis explores the foundational principles of LCA, its specific application to laboratory consumables, and the pathways for integrating this methodology into everyday laboratory practice.

The Foundational Principles of Life Cycle Assessment (LCA)

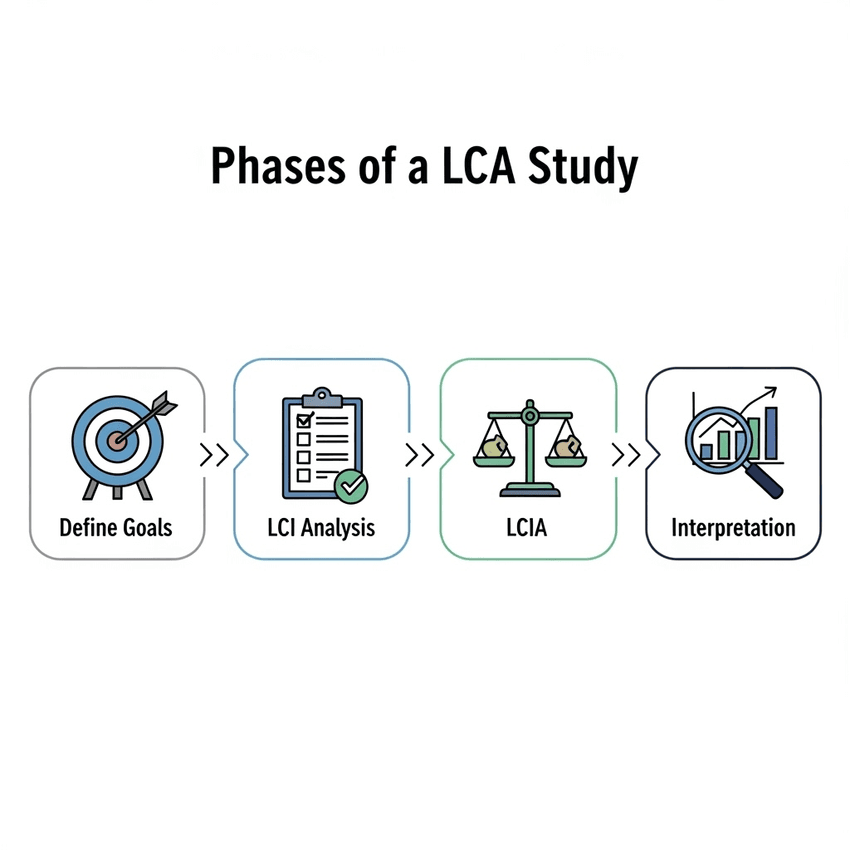

LCA is a standardized, scientific methodology that evaluates the environmental impact of a product system over its entire life cycle. It is a "cradle-to-grave" analysis that accounts for all inputs (e.g., raw materials, energy) and outputs (e.g., emissions, waste) at each stage. The methodology is defined by ISO standards 14040 and 14044, which provide a rigorous framework for conducting a study. A full LCA study consists of four interconnected phases:

Conducting a LCA study consists of four main phases.

GEMINI (2025)

- Goal and Scope Definition: This is the planning phase, where the purpose of the study is clearly stated, and the system boundaries are defined. This includes specifying the product or process being assessed, the functional unit (e.g., one liter of solvent), the time horizon, and the types of environmental impact to be evaluated. For a laboratory, this might involve comparing the environmental burden of a disposable plastic reagent bottle versus a reusable glass alternative over a specific number of uses.

- Life Cycle Inventory (LCI) Analysis: The most data-intensive phase, LCI involves compiling a detailed inventory of all material and energy inputs and outputs associated with the product system. This includes everything from the electricity consumed to produce a chemical to the emissions generated by its transport and the waste produced at its end-of-life. Data collection can be challenging, often requiring information from suppliers, manufacturing reports, and scientific databases.

- Life Cycle Impact Assessment (LCIA): In this phase, the LCI data is translated into meaningful environmental categories. The raw inventory data (e.g., kilograms of carbon dioxide, liters of water) is converted into quantifiable impacts, such as global warming potential (to calculate the carbon footprint), eutrophication, acidification, and resource depletion. This step allows for a direct comparison of different materials or processes based on their quantified environmental burdens.

- Life Cycle Interpretation: The final phase involves a critical review of the findings from the LCI and LCIA. The results are summarized and interpreted in the context of the initial goal and scope. This phase includes identifying key environmental hotspots, evaluating the robustness of the data, and providing conclusions and recommendations for decision-makers. It is where the raw data is transformed into actionable insights for improving materials sustainability and reducing overall environmental impact.

Mapping the Environmental Impact of Laboratory Materials

Applying the LCA methodology to laboratory consumables reveals a complex picture of their environmental impact. The life cycle of a single-use plastic pipette tip, for instance, starts long before it arrives at the lab bench.

Raw Material Extraction: The life cycle begins with the extraction of crude oil, a non-renewable resource, which is then refined into the plastic polymer used for the tip. This process involves significant energy use and emissions.

Manufacturing and Production: The refined polymer is transported to a manufacturing facility where it is molded, sterilized, and packaged. This stage requires considerable energy, often powered by fossil fuels, and generates emissions from industrial processes. The packaging itself, typically plastic bags and cardboard boxes, adds its own carbon footprint.

Transportation and Distribution: The finished product is then transported via trucks, ships, or planes to distributors and finally to the laboratory. Each leg of this journey contributes to the overall carbon footprint through fuel consumption and associated emissions.

Use Phase: In the laboratory, the pipette tip is used once and then discarded. The impact during this phase is minimal for a simple consumable like a pipette tip, but for energy-intensive equipment, this phase is often the most significant contributor to the life cycle environmental impact.

End-of-Life: For most single-use plastic lab materials, this stage involves collection and disposal via incineration or landfill. Incineration can release pollutants and greenhouse gases, while landfill disposal contributes to long-term plastic waste accumulation and land degradation. While some laboratories have recycling programs, contamination and the specific type of plastic often limit the effectiveness of these efforts.

A comprehensive life cycle assessment considers all these stages. For example, a single-use plastic item may have a lower manufacturing carbon footprint than its reusable glass counterpart, but when its full life cycle is considered, including the energy and water required to wash and sterilize the reusable item over hundreds of uses, the reusable option may ultimately demonstrate superior materials sustainability. The LCA approach provides the data needed to make these nuanced comparisons and move beyond simple assumptions about material choices.

Practical Application of LCA for Sustainable Laboratories

The power of LCA lies in its ability to guide concrete actions. By providing quantitative data on the environmental impact of different choices, LCA can revolutionize procurement and operational protocols in the lab. For instance, a comparative LCA might reveal that a specific sterile-filtered pipette tip from a supplier with an overseas manufacturing site has a larger carbon footprint than a similar product from a local supplier, even if the domestic item costs slightly more. This allows a lab to balance cost against its sustainability goals.

The selection of solvents is another prime example. A greener solvent may have a higher purchase cost, but its use could lead to a significant reduction in waste disposal costs and a lower overall environmental impact. An LCA can quantify this trade-off, showing the long-term benefits of a more sustainable option. Furthermore, the principles of LCA can inform the design of experiments, encouraging researchers to minimize reagent quantities and optimize processes to reduce consumption.

Key areas where LCA can be practically applied to advance materials sustainability include:

- Procurement Decisions: Using LCA data as a metric alongside cost and performance to select products with a lower environmental impact. This includes prioritizing products with recycled content, minimal packaging, and suppliers who are transparent about their supply chain and manufacturing processes.

- Waste Reduction and Management: Identifying the most burdensome end-of-life streams and exploring alternatives such as recycling programs, material recovery, or a shift to reusable options. For example, a lab’s LCA could show that a specific category of plastic gloves contributes disproportionately to the lab’s overall carbon footprint and lead to a decision to implement a specialty recycling program.

- Supplier Engagement: Encouraging suppliers to provide transparent LCA data for their products. As more laboratories demand this information, manufacturers will be incentivized to improve the materials sustainability of their offerings.

- Operational Efficiency: Optimizing experimental workflows to reduce the number of consumables used. Small changes, such as using micro-pipettes for smaller sample volumes, can cumulatively reduce a lab’s carbon footprint and material waste.

The Role of Digital Tools and Databases in LCA

Conducting a full-scale life cycle assessment can be a complex and time-consuming process, requiring access to extensive data on material and energy flows. Fortunately, the rise of specialized software and public databases has made LCA more accessible to non-experts. These digital tools provide pre-built life cycle inventory data for a vast range of materials and processes, simplifying the analytical process.

LCA software platforms allow users to build models of their lab processes, input material quantities and energy consumption, and generate comprehensive environmental impact reports. These tools automate the calculations, ensuring that the results are consistent and comparable. Moreover, open-source and commercial databases offer granular data on the carbon footprint and other environmental impact categories for thousands of chemicals, plastics, and industrial processes.

While these tools are invaluable, a basic understanding of LCA principles remains essential to ensure the integrity of the analysis. The "garbage in, garbage out" principle applies; the quality and accuracy of the final report are directly dependent on the data entered. Proper goal and scope definition, along with a critical interpretation of the results, are still crucial steps that require a thoughtful approach.

Advancing Laboratory Sustainability with Life Cycle Assessment

The integration of LCA into laboratory operations offers a powerful and structured pathway to achieving genuine materials sustainability. By moving beyond simplistic metrics and embracing a comprehensive "cradle-to-grave" analysis, laboratories can accurately identify their most significant sources of environmental impact and take targeted action to reduce them. LCA is not merely an academic exercise; it is a practical tool that provides the evidence needed to make smarter, more sustainable decisions—from selecting the right consumables to optimizing entire research workflows. As the scientific community continues to prioritize its ecological responsibilities, the principles and applications of life cycle assessment will become indispensable for creating laboratories that are not only scientifically innovative but also environmentally responsible.

Frequently Asked Questions (FAQs) about Life Cycle Assessment

What is the primary purpose of a life cycle assessment?

The primary purpose is to quantify and evaluate the environmental impact of a product, process, or service from raw material extraction through to its end-of-life, providing a comprehensive and data-driven analysis.

How does a life cycle assessment measure a carbon footprint?

Within a life cycle assessment, the carbon footprint is measured during the Life Cycle Impact Assessment phase by converting all emissions of greenhouse gases (like carbon dioxide, methane, and nitrous oxide) from every stage of the life cycle into a single metric known as Global Warming Potential (GWP), typically expressed in kilograms of carbon dioxide equivalents.

What are the key stages of a life cycle assessment?

The four key stages of a life cycle assessment are: Goal and Scope Definition, Life Cycle Inventory Analysis, Life Cycle Impact Assessment, and Life Cycle Interpretation.

Why is LCA important for materials sustainability in a lab?

Life cycle assessment is crucial for materials sustainability in a lab because it provides a holistic view of the environmental impact of consumables, allowing for data-backed decisions on procurement, waste management, and operational efficiency to reduce the overall carbon footprint of research.