Instruments such as mass spectrometers, electron microscopes, and high-performance liquid chromatographs are significant investments, and their proper functioning is non-negotiable for producing accurate, reproducible data. The proactive approach to equipment maintenance stands in stark contrast to reactive, "fix-it-when-it-breaks" models, which can lead to costly downtime, missed deadlines, and compromised results. Preventive maintenance is a systematic strategy that involves routine, scheduled tasks designed to minimize the likelihood of equipment failure and to preserve the instrument's operational integrity over time.

A robust lab equipment care program hinges on several key elements: clear Standard Operating Procedures (SOPs), detailed maintenance logs, and a culture that values proactive upkeep. Documentation is critical for maintaining consistency, tracking the instrument's history, and identifying recurring issues. Comprehensive equipment maintenance records should include dates of service, types of tasks performed, parts replaced, and any observed anomalies. This meticulous approach to lab equipment care not only ensures instrument reliability but also serves as a vital component of quality management systems and regulatory compliance.

The Critical Role of Instrument Calibration

While equipment maintenance focuses on the physical and mechanical upkeep of an instrument, instrument calibration is a specialized procedure that ensures the accuracy and precision of its measurements. Calibration is the process of comparing a measuring instrument to a standard of known accuracy to verify its performance. This step is essential for any laboratory where data integrity is paramount, as a miscalibrated instrument can produce inaccurate data that may lead to flawed conclusions or non-compliant products.

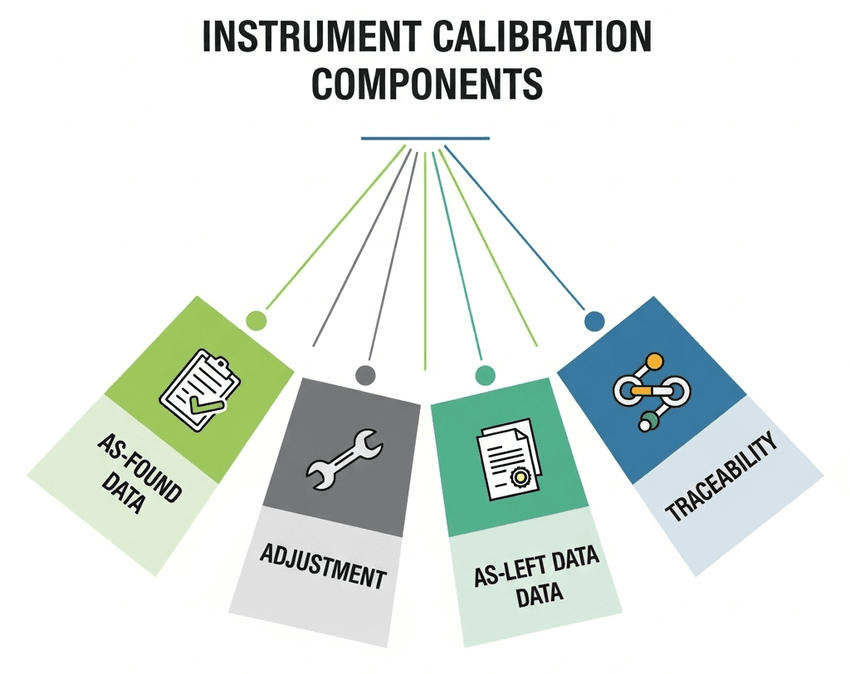

Regular instrument calibration is not merely a formality; it is a fundamental requirement for maintaining the scientific validity of research and the quality of manufactured goods. The frequency of calibration depends on several factors, including the instrument's usage, its manufacturer's recommendations, and the required level of accuracy for the applications. Key components of instrument calibration include:

There are several key components of instrument calibration.

GEMINI (2025)

- As-Found Data: The initial measurement taken before any adjustments are made to the instrument.

- Adjustment: The process of bringing the instrument's performance into alignment with the specified standard.

- As-Left Data: The final measurement taken after adjustment, confirming that the instrument is now within its specified tolerance.

- Traceability: The unbroken chain of comparisons to a national or international standard, ensuring the reliability of all measurements.

Proper instrument calibration is a cornerstone of instrument reliability and is often a requirement for certifications and audits, underscoring its importance beyond routine lab equipment care.

Best Practices for Common Lab Equipment

Implementing a tailored preventive maintenance plan for each piece of equipment is crucial for long-term instrument reliability. While specific needs vary, a number of general best practices can be applied to common instrument types.

Instrument Type | Routine Maintenance Tasks | Key Considerations |

|---|---|---|

Spectrometers | Lamp replacement, cleaning of optical lenses, detector alignment, verifying wavelength accuracy. | Environmental factors like dust and humidity can severely impact optical components. |

Microscopes | Cleaning objectives and eyepieces, checking stage movement, lubricating mechanical parts. | Handling with care is critical; fingerprints and scratches can degrade image quality. |

Chromatographs | Replacing pump seals and filters, cleaning injection ports, changing mobile phase solvents, column care. | Solvent purity and proper purging of lines are essential to prevent system contamination and blockages. |

Centrifuges | Rotor inspection for cracks, cleaning of the bowl, balancing the load, verifying RPM accuracy. | Rotor imbalances can cause catastrophic failure. Always check for damage before use. |

Adhering to these specific guidelines for lab equipment care is vital for preventing unexpected instrument failure and maintaining peak performance. This proactive approach to equipment maintenance significantly extends the lifespan of expensive instruments and safeguards the integrity of data.

Troubleshooting and Early Intervention

A key aspect of effective equipment maintenance is the ability to recognize early warning signs of potential issues. Ignoring subtle performance degradation can lead to more significant, and often more expensive, failures down the line. A slight deviation in a baseline, a new noise during operation, or a change in a sample's signal-to-noise ratio can all be indicators that a piece of equipment requires attention.

For complex instruments with integrated software, timely updates are part of the preventive maintenance schedule. Manufacturers frequently release software patches that address bugs, improve performance, or enhance data security. Furthermore, a consistent data backup routine is a non-negotiable part of lab equipment care. The loss of critical research data due to an instrument failure can be as devastating as the equipment failure itself. A proactive approach that combines keen observation with a systematic schedule for software updates and data backups ensures sustained instrument reliability.

Ensuring the Longevity of Lab Equipment

Beyond routine equipment maintenance, several environmental and operational factors contribute to the long-term health and instrument reliability of characterization equipment. Maintaining a stable laboratory environment, with controlled temperature and humidity, is essential for protecting delicate electronics and mechanical components. Additionally, ensuring a clean and dust-free workspace around sensitive instruments is a simple but highly effective form of lab equipment care.

The human element is also a critical factor. Proper training for all personnel who operate the equipment minimizes the risk of user-induced errors and accidental damage. A well-trained operator is more likely to handle an instrument correctly, follow SOPs, and report potential issues promptly. By investing in comprehensive preventive maintenance, rigorous instrument calibration, and proper user training, a laboratory can significantly extend the operational life of its characterization equipment, ensuring that its scientific capabilities remain at the forefront of research and analysis for years to come.

Frequently Asked Questions on Lab Equipment Care

Why is preventive maintenance for lab equipment so important?

Preventive maintenance is crucial for minimizing unexpected instrument downtime, reducing the risk of costly repairs, ensuring the reliability of research data, and extending the overall lifespan of valuable lab equipment.

How often should instrument calibration be performed?

The frequency of instrument calibration is determined by a number of factors, including the manufacturer's recommendations, the instrument's usage frequency, the required level of measurement accuracy, and regulatory requirements. Critical instruments may require more frequent calibration than others.

What are common signs that a piece of lab equipment needs servicing?

Common signs that equipment requires servicing include a decrease in measurement accuracy, an increase in background noise, unusual sounds or vibrations during operation, or error messages that are not resolved by standard troubleshooting steps.

What is the primary difference between equipment maintenance and instrument calibration?

Equipment maintenance refers to the physical care and upkeep of an instrument to ensure its proper function (e.g., cleaning, replacing parts), whereas instrument calibration is the process of verifying and adjusting an instrument's measurements against a known standard to ensure data accuracy.