In most analytical laboratories, the "Radiation Hazard" sign is typically associated with high-energy equipment like X-Ray Diffraction (XRD) units or nuclear magnetic resonance (NMR) sources. Vibrational spectroscopy suites—housing FTIR (Fourier Transform Infrared) and NIR (Near-Infrared) instruments—are often viewed as benign environments where the primary risks are chemical rather than radiological. After all, traditional spectrometers have relied on simple, incoherent light bulbs (Globar or Tungsten-Halogen) as sources, which pose little risk to the user.

However, for the Laboratory Manager, this assumption of safety can be a significant liability. Every standard FTIR contains a laser for calibration, and the next generation of infrared analyzers utilizes high-power Quantum Cascade Lasers (QCLs) that pose immediate, permanent risks to vision. As spectroscopy evolves from weak thermal sources to highly coherent and powerful laser sources, laboratory safety protocols must evolve with them. This guide outlines the hidden dangers in your spectroscopy bench and how to specify the correct Personal Protective Equipment (PPE) to ensure a robust laser safety culture.

Laser Safety and the Hidden Danger: The HeNe Reference Laser

Open the hood of virtually any FTIR spectrometer—from a benchtop routine unit to a high-end research system—and you will find a Helium-Neon (HeNe) laser. While the infrared source does the analytical work, this secondary laser is the heartbeat of the instrument's precision.

- The Purpose: The HeNe laser (emitting visible red light at 632.8 nm) acts as an internal ruler. It tracks the position of the moving mirror in the interferometer with extreme precision, allowing the instrument to perform the Fourier Transform.

- The Risk: In normal operation, the instrument is a Class 1 Laser Product, meaning the laser is fully enclosed and safe. However, during maintenance, optical alignment, or "open beam" experiments, the interlocks may be defeated.

- The Hazard Class: These internal lasers are typically Class 2 (< 1 mW) or Class 3R (1–5 mW). While the blink reflex usually protects against accidental exposure, a direct hit from a Class 3R beam during intricate alignment work can cause retinal damage.

Emerging Laser Safety Challenges: Quantum Cascade Lasers (QCL)

The landscape of infrared analysis is shifting toward QCLs. These tunable lasers offer brightness orders of magnitude higher than traditional sources, enabling stand-off detection and rapid imaging, but they introduce a new tier of laser safety risks that many labs are unprepared for.

- The Wavelength: Mid-IR (typically 4 µm – 12 µm).

- The Danger: Unlike the red HeNe laser, QCL beams are invisible. The human eye does not register the beam, meaning there is no blink reflex.

- The Injury: High-power QCLs (Class 3B or Class 4) can burn the cornea or retina instantly. Because the beam is invisible, an analyst may not even realize they have been exposed until vision loss occurs or they feel a "pop" on the surface of the eye.

Selecting LEP for Rigorous Laser Safety

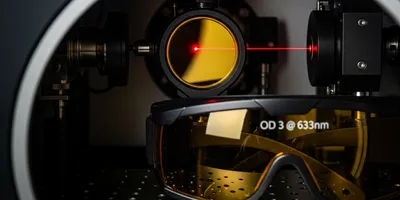

Buying "laser goggles" from a general safety catalog is insufficient and potentially dangerous. To ensure effective laser safety, you must match the specifications of the eyewear—specifically, Optical Density (OD) and wavelength coverage—to the specific source inside your instrument.

1. Optical Density (OD)

OD measures how much the eyewear attenuates the beam. It is logarithmic.

- OD 1: Blocks 90% of light.

- OD 3: Blocks 99.9% of light.

- Requirement: For a typical FTIR HeNe alignment, OD 2 or 3 at 633 nm is standard. For QCLs, the OD requirement depends on the laser power but often requires OD 5+ in the specific IR range (e.g., 5000–10000 nm).

2. Visible Light Transmission (VLT)

This is the "sunglasses effect." High OD is useless if the goggles are so dark the analyst cannot see the keyboard.

- The Balance: You want the highest VLT possible while maintaining the required OD. Modern polymer filters often offer >30% VLT, which is comfortable for indoor lab work.

3. Alignment vs. Full Block

- Full Block: Blocks the beam entirely.

- Alignment Filter: Allows a tiny fraction of visible light through so the analyst can see where the red HeNe beam is pointing (to align mirrors) without being blinded. Crucial for FTIR service engineers.

Manager's Memo: Establishing a Laser Safety Culture

The most dangerous tool in the lab is often a simple piece of tape used to bypass a safety mechanism. Operational pressure can sometimes lead researchers to take shortcuts, but in the context of laser safety, these shortcuts can be blinding.

- The Problem: Researchers often tape over safety interlocks to run "custom" experiments or oversized samples that don't fit in the compartment. This converts a safe Class 1 device into a dangerous Class 3B open-beam system.

- The Policy: Establish a strict "Zero-Bypass" rule. If an experiment requires defeating an interlock, it requires a temporary Laser Controlled Area (LCA) setup, including warning signs, dedicated eyewear, and restricted access.

Purchasing Guide: What to Look For

When upgrading your lab's safety gear, attention to detail is critical. Generic specifications often miss the nuance required for spectroscopy applications, leading to purchases that are either non-compliant or functionally useless for the specific wavelengths involved.

Feature | Specification to Check | Why it Matters |

|---|---|---|

Wavelength Matching | Exact nm range (e.g., 633 nm for HeNe) | Goggles for a YAG laser (1064 nm) offer zero protection for an FTIR HeNe laser (633 nm). |

Fit Over Prescription | "Fit-over" style | Many analysts wear glasses. Ensure the LEP frames fit comfortably over standard eyewear to prevent non-compliance. |

Damage Threshold | Power density rating | For high-power QCLs, plastic lenses might melt. Glass filters may be required for Class 4 systems. |

Certification | ANSI Z136.1 or EN 207 | Ensure the eyewear meets the recognized safety standards for your region. |

Conclusion: Visibility is Key to Laser Safety

The integration of laser sources into vibrational spectroscopy has revolutionized the sensitivity and speed of chemical analysis, but it has also elevated the risk profile of the standard analytical bench. By recognizing that "invisible" does not mean "safe," and by implementing rigorous laser safety protocols—from appropriate eyewear to strict interlock policies—laboratory managers can protect their most valuable asset: their staff. As technology advances towards brighter, more powerful QCL sources, a proactive stance on laser safety will distinguish the world-class laboratory from the liable one.