The research team formed by the Department of Mechanical Engineering of Toyohashi University of Technology, Professor Asahiro Nagatani of Hyogo Prefectural Institute of Technology (currently the National Institute of Advanced Industrial Science and Technology), and Professors Nobuyoshi Tsujiuchi and Akihito Ito of the Science and Engineering Department of Doshisha University found out by using the synchrotron radiation X-ray computed tomography (CT) that the improved vibration damping of rubber materials associated with the compounding of fine particles is related to the deformation behavior of the microstructure. They discovered that performing deformation evaluations at the macroscale (in the order of mm) and at the microscale (space resolution when using the X-ray CT: 500nm) at the same time can obtain the internal nonuniform deformation of a material in the scale of several dozens mm. The results of the research were released online in Polymer Testing.

For machine structures, it is vitally necessary that vibrations and noises be appropriately controlled to ensure performance and safe operation. There are many cases where design limits and operating limits are determined by damping properties, which control the amount of vibration. Generally, energy loss caused by the deformation of rubber (a determination factor in vibration damping) is described as a loss caused by the change of the arrangement of the filler particles blended into the polymer (pain effect). As an experimental rule of macro mechanical properties, it is believed that its main control factors are the diffusion, interface, and orientation of the filler. However, technologies predicting damping properties based on these main control factors have not been established yet. One of the reasons is the difficulty of observing three-dimensional structures.

Transmission electron microtomography (TEMT) and X-ray Computed Tomography are methods of observing the three-dimensional structure of a high polymer material. TEMT requires the thickness of a specimen to be several hundreds of nm, and one problem with it is that it tends to generate artifacts (false images). It is difficult to obtain image contrast in X-ray CT, and there are fewer cases of application for polymer materials when compared to TEMT. Furthermore, when examining rubber materials, another problem of X-ray CT is that the sample's physical properties change due to a curing reaction due to exposure to X-ray radiation. Because the sensitivity of image sensors and high-speed radiographic technologies have improved gradually in recent years, it is now possible to obtain CT images with contrast with only short-term X-ray radiation exposure.

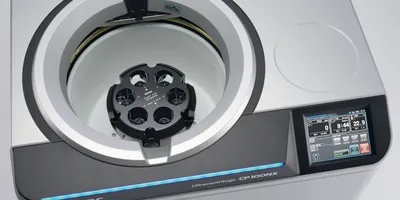

Therefore, the research team used a synchrotron radiation facility to perform micro X-ray CT of fine particle-filled rubber materials in a tiny deformation field. They developed a compact tensile tester that can be mounted on X-ray CT machines and also evaluated deformation behavior at the macroscale using the tensile test. Based on the evaluation result at the macroscale, they found out that in the deformation area that can be judged as an elastic deformation area, deformation at the microscale became nonuniform according to the amount of change.

Development background

In the vibration field, the damping property is a parameter that is observed under dynamic conditions. On the other hand, from the viewpoint of material development, the damping property should be determined at the time when the structure is determined. Therefore, they expected that even a static deformation would make a difference and tried to measure it using the micro X-ray CT.

Future outlook

Currently, the research team is attempting to perform dynamic X-ray CT. They expect this to clarify the deformation behavior of an internal structure at the mesoscale and the relationship between the control factors associated with a filler and its damping properties.

- This press release was provided by the Toyohashi University of Technology website