Effective lab operations are the critical foundation supporting high-quality scientific output and industrial compliance. The ability of a modern laboratory to deliver accurate, reproducible, and timely results depends entirely on the design and execution of its internal and external processes. Scaling research, diagnostic testing, or quality control requires a sophisticated framework that seamlessly manages sample flow, data generation, and resource allocation. The complexity is often compounded by the need to handle disparate systems and instruments within the same environment. Therefore, a strategic approach to optimizing operational design is essential for transitioning from reactive management to a proactive, reliable, and scalable scientific enterprise.

Integrated Workflow Design for Modern Lab Operations and Multi-Tech Workflows

Designing effective lab operations necessitates a holistic view of the entire analytical process, treating the laboratory as an integrated system rather than a collection of disparate instruments. This systems-based perspective is particularly critical when managing multi-tech workflows that involve sequential steps across different analytical platforms, such as transitioning a sample from genomics extraction to mass spectrometry, and finally to advanced computational analysis. Efficiency is maximized when friction points between these technological silos are systematically removed.

Integrated workflow design focuses on standardizing handoffs—physical, digital, and procedural—to ensure consistency and reduce processing errors. A core element is the meticulous mapping of all steps, documenting input requirements, output specifications, and critical quality control (QC) checkpoints. For high-volume environments, this map becomes the blueprint for minimizing dwell time and maximizing resource utilization.

The implementation of Laboratory Information Management Systems (LIMS) or Electronic Lab Notebooks (ELNs) serves as the central nervous system, automating data capture and providing visibility across the entire workflow. For instance, an integrated system can automatically schedule downstream instrument use based on the completion of an upstream step, ensuring resources are utilized optimally without idle time. This level of integration is paramount for laboratories seeking certification or accreditation, as it provides an auditable trail for every stage of sample handling and data generation, significantly reinforcing the reliability of the final scientific outcome.

Key considerations for designing integrated multi-tech workflows include:

- Data Structure Harmonization: Ensuring that data output formats from various instruments (e.g., spectrophotometers, sequencers) are compatible and automatically ingestible by the central data management platform without manual transformation.

- Interface Layer Standardization: Using a limited set of standardized protocols (e.g., API calls, structured file formats) for communication between instrumentation and software layers, simplifying integration and maintenance.

- Error Correction and Notification: Implementing automated checks and alerts at critical handoffs, which signal procedural deviations or measurement inconsistencies before the sample proceeds to the next high-value step.

This meticulous approach to workflow integration builds a robust, transparent operational structure that supports both current demands and future scalability requirements.

Safeguarding Sample Integrity: Robust Chain-of-Custody in Lab Operations

The reliability of any laboratory result is fundamentally dependent on the quality and authenticity of the initial material. Maintaining sample integrity is therefore non-negotiable and must be assured through rigorous procedures backed by an unassailable chain-of-custody (CoC) system. In regulated environments, or where forensic standards apply, the CoC documentation proves that the sample’s identity and physical condition remained uncompromised from collection to final disposition.

A robust CoC process begins immediately upon sample acquisition, whether that occurs in a clinical setting, an industrial site, or the research field-to-lab pipeline. Unique identifiers (UIDs), typically in the form of secure barcodes or RFID tags, are assigned and permanently affixed to the primary container. This UID must be linked to comprehensive metadata that details the sample origin, collection time, collector identity, and any initial preservation methods.

The CoC system must track and record every physical movement and interaction with the sample, including transfers between personnel, storage conditions (e.g., temperature excursions), and aliquoting events. This process is best managed by a centralized, digital system that automatically logs time, date, and user identity for each interaction, minimizing the possibility of human error inherent in paper-based logs.

Pillars of Sample Integrity and CoC

Pillar | Operational Requirement | Impact on Reliability |

|---|---|---|

Secure Identification | Use of unique, non-reusable, and durable identifiers (2D barcodes, RFID). | Prevents cross-contamination and mislabeling errors. |

Environmental Monitoring | Continuous, validated monitoring of storage conditions (± 0.5∘ C accuracy) for freezers, refrigerators, and ambient storage. | Ensures biochemical stability of analytes over time. |

Digital Logging | Automated recording of all access, aliquoting, and transfer events by date, time, and authenticated user. | Establishes a legally defensible and auditable timeline of custody. |

Aliquoting Protocol | Standardized, low-risk procedures for sub-sampling, minimizing freeze-thaw cycles and contamination risk. | Preserves the representativeness of the original sample material. |

By prioritizing the maintenance of sample integrity and implementing an unbreakable chain-of-custody, the laboratory establishes a bedrock of trustworthiness for all resulting data, a requirement for any high-volume or critically important testing operation.

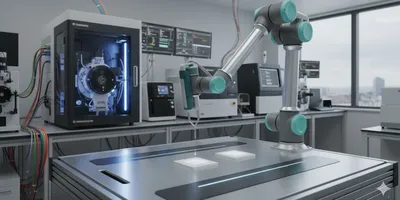

Automation Strategies: High-Throughput, Prototyping, and High-Volume Lab Operations

The strategic deployment of automation technologies fundamentally redefines the capabilities and operational envelope of modern lab operations. Automation is typically associated with high-throughput (HT) screening and large-scale, repetitive tasks, but its utility extends critically to the rapid development and validation inherent in prototyping new assays.

In high-throughput scenarios, liquid handling robots and integrated workstations ensure precise, repeatable execution of complex protocols, dramatically exceeding the speed and consistency achievable by manual methods. This not only accelerates data generation but also enhances reliability by eliminating stochastic human variation. The resulting improvement in coefficient of variation (CV) for assays is a direct operational benefit. Furthermore, 24/7 operation capabilities allow laboratories to process high-volume batches without interruption, significantly shortening turnaround times.

Conversely, in the context of prototyping new assays or optimizing existing ones, automation facilitates rapid iteration. Once a preliminary protocol is designed, it can be quickly programmed and executed on a robotic platform. The robot can systematically vary critical parameters (e.g., reagent concentration, incubation time, mixing speed) across hundreds of experimental conditions in a controlled, matrixed fashion. This "Design of Experiments" approach, which would be impractical manually, allows scientists to quickly define the optimal operational parameters and robustness boundaries of the new assay.

Strategic Uses of Laboratory Automation

- High-Throughput (HT) Execution:

- Goal: Maximize sample processing volume and speed.

- Technology: Fully integrated robotic cells handling everything from sample plate de-capping to final result generation.

- Operational Metric: Samples processed per hour (SPH) and total run time.

- Prototyping and Assay Validation:

- Goal: Rapidly test and optimize protocol variables for new multi-tech workflows.

- Technology: Flexible liquid handlers capable of executing complex, user-defined, non-standard pipetting patterns and variable volume transfers.

- Operational Metric: Number of unique experimental conditions tested per day.

This duality—using automation for both production-scale high-throughput and rapid prototyping—demonstrates the versatility required in advanced lab operations. The integration of automated systems must be supported by robust informatics that allow seamless method development and data acquisition across the entire operational spectrum.

Resource Optimization: Mastering Shared Facilities in Lab Operations

Laboratories increasingly rely on shared facilities, core labs, or institutional instrumentation centers to access specialized, high-cost equipment and expertise. Efficient lab operations in this context shift from managing solely internal resources to expertly coordinating access, maintenance, and usage across a diverse user base. Poor resource management in these environments can lead to significant bottlenecks, impacting overall scientific productivity and the cost-effectiveness of these capital investments.

The optimization strategy for shared facilities revolves around three key areas: access governance, utilization tracking, and maintenance scheduling.

- Access Governance: Implementation of a centralized, cloud-based booking system is mandatory. This system must enforce fair use policies and provide a transparent, reliable view of equipment availability. Effective governance also includes standardized training and certification requirements to ensure that only qualified personnel operate highly specialized instruments, thereby protecting the longevity of the resource and maintaining data quality.

- Utilization Tracking: Simply booking equipment is insufficient; actual utilization must be tracked. Integrating instrument data logging with the booking system provides accurate metrics on equipment runtime, idle time, and the duration of maintenance events. Analyzing this data allows the facility manager to identify underutilized resources that could be repurposed or heavily oversubscribed instruments that may require the procurement of a second unit to sustain high-volume needs. This data-driven approach to resource planning is vital for optimizing operational spend.

- Preventative Maintenance (PM) Scheduling: Downtime in shared facilities impacts dozens of projects, so proactive PM is non-negotiable. The booking system should automatically flag maintenance windows based on calendar time and/or usage hours logged by the instrument. This systematic scheduling, often mandated by equipment service contracts, prevents catastrophic failure, maintains instrument calibration, and contributes to the overall reliability of the data generated across all supported multi-tech workflows.

By creating a transparent and data-managed system within shared facilities, laboratories transform a potential source of operational conflict into a force multiplier for scientific capability and efficiency.

Field-to-Lab Connectivity: Scaling Lab Operations with Sample Integrity

The modern scope of lab operations frequently extends far beyond the physical confines of the laboratory bench, often requiring the capture and transfer of samples and data from remote locations. Establishing robust field-to-lab connectivity is a vital element for any organization seeking to achieve geographic scalability and maintain stringent standards for sample integrity during transit.

The primary operational challenge in the field-to-lab process is bridging the gap between sample collection logistics and the laboratory's informatics system. This requires a digital strategy for data acquisition and transfer that is secure and standardized. Mobile applications or ruggedized data capture devices used at the collection site should be configured to immediately associate key metadata—GPS coordinates, environmental readings, time stamp, and initial preservation details—with the sample's unique identifier.

This initial data capture is essential for initiating the digital chain-of-custody before the physical sample even arrives. Upon receipt, the laboratory's LIMS should be capable of automatically ingesting the field-collected data by scanning the sample container's UID, thus eliminating manual data entry and transcription errors.

Operational Requirements for Field-to-Lab Scalability

Requirement | Description | Operational Benefit |

|---|---|---|

Standardized Kits & Protocols | Pre-packaged collection kits and defined, easily executable protocols for field personnel. | Ensures consistency in sample integrity across diverse collection sites. |

Digital CoC Initiation | Immediate electronic logging of collection data and initiation of the chain-of-custody via mobile device. | Reduces data entry errors and provides immediate visibility into incoming samples. |

Validated Transit Conditions | Use of temperature-logging shippers and validated transportation routes to minimize environmental risks. | Protects sample quality during transit, a critical lab operations component. |

LIMS Auto-Ingestion | Ability of the Laboratory Information Management System to automatically parse and import field data upon arrival. | Accelerates sample processing and enhances data reliability. |

By prioritizing secure, automated field-to-lab data and sample management, organizations can scale their collection efforts geographically while upholding the high standards of lab operations required for reliable scientific outcomes.

Achieving Operational Excellence in Lab Operations

The goal of mastering lab operations transcends mere efficiency; it is a strategic imperative that directly impacts scientific innovation, compliance adherence, and economic viability. The implementation of cohesive, integrated systems—from the management of shared facilities to the deployment of automation in high-throughput assays—is essential for achieving operational excellence. Building robust multi-tech workflows supported by rigorous protocols ensures that data generation is not only rapid but also scientifically defensible. Furthermore, prioritizing sample integrity and meticulous chain-of-custody procedures, especially in field-to-lab scenarios, establishes a foundation of trust in the laboratory's output. The successful laboratory leverages digital tools to connect every phase, from early-stage prototyping through to high-volume production, thus guaranteeing reliability and facilitating responsive scalability in an ever-evolving scientific landscape.

Frequently Asked Questions (FAQ)

How does automation specifically support both high-volume throughput and assay prototyping within lab operations?

Automation is a dual-purpose asset in lab operations. For high-volume throughput, integrated robotic systems execute routine assays with superior speed and consistency, allowing for 24/7 operation and a substantial increase in samples processed per unit of time, which is the definition of high-throughput. For prototyping, the same robotic systems offer unparalleled flexibility for systematic method development. They can precisely execute complex experimental matrices, rapidly testing numerous variable combinations (e.g., reagent concentrations, incubation times) to optimize new assays or troubleshoot existing multi-tech workflows. This rapid, automated design of experiments (DoE) accelerates the critical validation phase before an assay is deployed at scale.

What are the key elements of a digital chain-of-custody system necessary to ensure sample integrity in a field-to-lab setting?

A digital chain-of-custody (CoC) system is essential for maintaining sample integrity when moving material from the field-to-lab. Key elements include secure unique identifiers (UIDs) assigned at the point of collection; mobile-based applications that electronically capture and geotag initial metadata (time, location, collector); and automatic time/user logging of every subsequent transfer, storage, and processing event. The system must also integrate environmental monitoring, logging temperature and humidity during transit to prevent compromise. This digital, auditable trail ensures that any deviations from standard operating procedures are immediately flagged, safeguarding the validity of the sample prior to laboratory analysis.

In the context of lab operations, how can shared facilities maximize resource efficiency and reduce operational bottlenecks?

Effective management of shared facilities involves optimizing resource allocation through transparent access and rigorous usage tracking. A centralized, digital scheduling platform is necessary to manage booking and prevent conflicts for specialized, high-throughput instrumentation. Beyond booking, efficiency is driven by integrating instrument usage logs with the scheduling system to track true utilization rates. This data enables managers to identify and address bottlenecks, such as consistently oversubscribed equipment, and to schedule proactive, use-based preventative maintenance (PM). Maximizing instrument uptime through systematic PM and optimizing user scheduling minimizes idle time and ensures maximum return on capital investment for the entire organization's lab operations.

Why are multi-tech workflows becoming standard, and what is the primary operational challenge they present?

Multi-tech workflows are becoming standard because modern scientific questions frequently require the sequential application of different technologies, such as linking cell culture (biology) with liquid chromatography (chemistry) and mass spectrometry (analytical physics). This integration allows for comprehensive analysis, supporting complex high-volume studies. The primary operational challenge lies in ensuring smooth, reliable handoffs between these technologically distinct platforms. This requires rigorous standardization of sample input and output requirements at each step, harmonizing data structures for seamless ingestion into a central LIMS, and implementing QC checkpoints to verify sample integrity and data quality before transitioning to the next technology in the workflow.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.