Particle size analysis for paints and coatings is a fundamental requirement for laboratory professionals seeking to ensure product performance, aesthetic quality, and long-term shelf stability. Understanding the distribution of pigment and binder particles allows manufacturers to predict key characteristics such as opacity, gloss, and rheological behavior. By employing standardized analytical techniques, labs can minimize defects like flocculation or sedimentation that compromise the integrity of the final film.

Why is particle size analysis for paints and coatings essential for formulation?

Particle size analysis for paints and coatings is the primary method for determining how individual components will interact to create a stable, high-performance suspension. The physical dimensions of pigment particles directly influence the surface area available for interaction with resins and solvents, which dictates the viscosity and chemical demand of the liquid product. If particles are too large, they may settle out of the solution prematurely; if they are too small or poorly distributed, they may lead to unintended color shifts or significantly reduced hiding power in the cured film.

Laboratory professionals often use the Hegman gauge according to the ASTM D1210 standard to determine the "fineness of grind" by identifying the largest particles or agglomerates in a dispersion. While the Hegman gauge provides a rapid visual check for oversized "grit," it does not provide the comprehensive particle size distribution (PSD) data necessary for advanced formulation. Consequently, PSD is measured by complementary instrumental methods like laser diffraction, which provides the quantitative data needed to correlate fineness of dispersion with the overall behavior of the coating system.

Consistent PSD monitoring also prevents the formation of aggregates and agglomerates during the high-energy milling process. Incomplete dispersion often results in "seeds" in the final film, which degrades both the visual appearance and the protective capabilities of the coating by creating pathways for moisture. Industry best practices recommend using laser diffraction or dynamic light scattering to verify that the grinding process has reached the optimal thermodynamic state for long-term stability.

Furthermore, particle size analysis for paints and coatings informs the calculation of the Critical Pigment Volume Concentration (CPVC). The CPVC is the point at which there is just enough binder to cover all pigment particles and fill the voids between them. Precise data on particle size allows chemists to optimize this ratio, ensuring that the coating maintains its structural integrity and corrosion resistance without using excessive, costly resins.

How does particle size influence the optical properties of coatings?

The optical performance of a coating, including its opacity, tinting strength, and gloss levels, is determined by how the particle size distribution interacts with the wavelengths of visible light. When the average diameter of a pigment particle is approximately half the wavelength of the target light spectrum, light scattering is maximized, leading to peak opacity. This principle is particularly vital for titanium dioxide (TiO₂), the most common white pigment, where a narrow size distribution around 200–250 nanometers is required for maximum hiding power.

Multiple studies published in the Journal of Coatings Technology and Research indicate that even minor deviations in the PSD can lead to significant batch-to-batch color variance. For metallic or pearlescent coatings, the orientation and size of effect pigments, such as aluminum flakes or mica, are even more sensitive to size constraints. Accurate particle size analysis for paints and coatings allows labs to maintain these tight tolerances, ensuring that the final product meets the specific aesthetic requirements of the automotive and decorative industries.

The relationship between particle size and refractive index is also a critical factor in optical design. According to Mie theory, the efficiency with which a particle scatters light depends on the ratio of its size to the wavelength of light and the difference in refractive index between the particle and the medium. Laboratory professionals use these mathematical models to select pigments that provide the highest possible contrast with the resin matrix, thereby maximizing the visual impact and coverage of the coating.

Gloss and sheen are similarly dependent on the physical dimensions of the particles at the air-film interface. Smaller, more uniform particles create a smoother surface at the microscopic level, which increases specular reflection and perceived gloss while reducing unwanted haze. Conversely, larger particles or matting agents are intentionally added to disrupt surface uniformity, providing the desired level of diffuse reflection for satin or matte finishes.

What techniques are used for particle size analysis for paints and coatings?

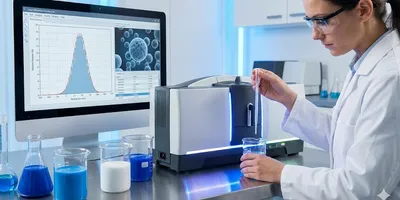

Laser diffraction is the most widely utilized technique for particle size analysis for paints and coatings because it offers a broad dynamic range and high reproducibility across various sample types. This method works by measuring the angle of light scattered as a laser beam passes through a dispersed particulate sample, with the scattering angle being inversely proportional to the particle size. This technique is suitable for both liquid dispersions and dry powders, making it versatile for different stages of the manufacturing and quality control workflow.

For sub-micron and nanoparticle systems, Dynamic Light Scattering (DLS) is the preferred analytical approach for modern, high-performance formulations. DLS measures the Brownian motion of particles in a suspension and relates this movement to the hydrodynamic diameter via the Stokes-Einstein equation. This is particularly useful for analyzing modern water-borne resins and nano-pigment dispersions where traditional diffraction may lack the necessary sensitivity for particles smaller than 100 nanometers.

Technique | Typical Range | Primary Application |

|---|---|---|

Laser Diffraction | 0.01 µm – 3500 µm | Pigment grinds, fillers, and general emulsions. |

Dynamic Light Scattering | 0.3 nm – 10 µm | Nano-dispersions, polymers, and binders. |

Static Image Analysis | 0.5 µm – 1000 µm | Shape characterization and detecting oversized grit. |

Acoustic Spectroscopy | 10 nm – 100 µm | Concentrated dispersions without dilution. |

The International Organization for Standardization (ISO) 13320 provides the framework for laser diffraction procedures, emphasizing the importance of proper sample preparation and detector alignment. Laboratory professionals must ensure that the sample is representative of the bulk material and that the dispersion medium does not cause the particles to swell or dissolve. Accurate refractive index values for both the particle and the medium are also necessary to apply Mie theory for the most precise results in complex mixtures.

Beyond size, automated shape analysis is becoming increasingly important for understanding how particles pack together in a dry film. These imaging systems can identify whether particles are spherical, needle-like, or plate-like, all of which affect the flow and reinforcement properties of the coating. Combining shape data with particle size analysis for paints and coatings provides a multi-dimensional view of the raw materials, leading to more predictable manufacturing outcomes.

How do particle size and distribution affect rheology and stability?

The rheological profile and long-term shelf stability of a product are directly governed by the results of particle size analysis for paints and coatings. Smaller particles have a higher surface-area-to-volume ratio, which generally increases the viscosity of the system due to higher inter-particle friction and stronger van der Waals forces. If the distribution is too broad, the smaller particles can fill the gaps between larger ones, which may lead to complex shear-thinning behavior or unexpected thickening during storage.

Stabilizing these systems requires a balance between particle size and the concentration of surfactants, polymers, or dispersants. According to the DLVO (Derjaguin, Landau, Verwey, and Overbeek) theory, stability is maintained when the repulsive forces outweigh the attractive forces between particles. If particle size analysis indicates the presence of large clusters or a shifting mean size over time, it is often a sign of flocculation, which can lead to syneresis or hard caking at the bottom of the container.

Furthermore, the settling velocity of particles is described by Stokes’ Law, which states that the rate of sedimentation is proportional to the square of the particle radius and the density difference between the phases. Therefore, reducing the particle size through efficient milling is a primary strategy for extending the shelf life of heavy, pigment-loaded coatings. Frequent testing during the development phase allows chemists to optimize the grind time and additive dosage to achieve a stable, homogenous mixture that remains viable for the duration of its intended storage period.

Effective rheology management also ensures that the coating performs correctly during application, whether by brush, roller, or spray. Particles that are too large can cause nozzle clogging in spray equipment or unwanted texture in brushed finishes. By maintaining a consistent particle size analysis for paints and coatings protocol, manufacturers can ensure that their products have the correct thixotropy, thinning under application stress but recovering quickly to prevent sagging.

How does industrial particle characterization support regulatory compliance?

Adherence to environmental and safety regulations often requires rigorous particle size analysis for paints and coatings to verify the absence or presence of specific materials. Many jurisdictions have strict reporting requirements for nanomaterials, defined as particles with at least one dimension between 1 and 100 nanometers. Accurate measurement ensures that manufacturers can provide the necessary documentation for REACH compliance in Europe or EPA regulations in the United States regarding chemical safety and exposure levels.

Furthermore, the transition to low-VOC (Volatile Organic Compound) and water-borne systems has made particle characterization more critical than ever. Water-borne binders often consist of polymer particles suspended in an aqueous phase, and their size distribution determines the film-forming temperature and the mechanical strength of the cured layer. Precise data allows labs to navigate the technical challenges of replacing traditional solvents with water-borne alternatives without sacrificing performance or durability.

In addition to safety, particle size analysis for paints and coatings supports sustainability goals by optimizing raw material usage. By ensuring the highest possible tinting strength through ideal particle sizing, manufacturers can achieve the same color intensity with less pigment. This reduction in material throughput lowers the carbon footprint of the production process and reduces the overall environmental impact of the product lifecycle.

Incorporating diverse raw materials in particle size analysis for paints and coatings

Particle size analysis for paints and coatings must account for the diverse physical properties of modern raw materials, including organic pigments, inorganic extenders, and polymeric binders. Inorganic fillers like calcium carbonate, kaolin clay, or talc often have non-spherical geometries, requiring image analysis or specialized shape-correction factors to complement traditional laser diffraction data. Organic pigments, while providing vibrant color, frequently exhibit higher cohesive forces, making them more prone to re-agglomeration if the dispersion energy is insufficient. By characterizing each component's unique size distribution independently before blending, laboratory professionals can predict how these materials will compete for dispersant coverage. This comprehensive approach ensures that the complex multi-component environment of a modern coating maintains its integrity from the initial mixing stage through to the final application on the substrate.

The move toward sustainable and bio-based raw materials introduces new variables into the analysis process. Bio-resins and natural pigments often have wider natural variations in particle size compared to synthetic counterparts. Robust particle size analysis for paints and coatings allows labs to adjust their formulations in real-time to compensate for these raw material fluctuations. This adaptability is essential for maintaining product quality while transitioning to greener chemistry in the global coatings market.

The inclusion of recycled materials or industrial byproducts as extenders also presents new challenges for the laboratory. These materials may contain a broader range of particle sizes or irregular contaminants that could disrupt the stability of the dispersion. Rigorous incoming material inspection using automated sizing techniques protects the production line from variability and ensures that the final product remains within the narrow performance specifications demanded by high-end industrial clients.

Conclusion: Particle size analysis for paints and coatings

Particle size analysis for paints and coatings is a vital quality control and R&D process that ensures the functional and aesthetic success of the final product. By controlling the particle size distribution, manufacturers can guarantee optimal light scattering for opacity, consistent rheological properties for application, and robust shelf stability. Utilizing standardized methods such as laser diffraction and DLS, backed by organizations like ISO and ASTM, provides the objective data necessary for high-performance formulation. Ultimately, precise particle size analysis for paints and coatings serves as the foundation for innovation in the industry, enabling the development of more durable and visually striking materials.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.