Rheology determines the flow and deformation behavior of industrial coatings and paints, directly impacting application efficiency and final film quality. Laboratory professionals must understand how rheological properties influence pumping, spraying, and leveling to prevent defects like sagging or brush marks. Consistent measurement of viscosity and viscoelasticity allows manufacturers to predict product performance under various shear conditions.

How shear rate influences viscosity profiles in coatings

Shear rate dependency defines how industrial coatings and paints behave during high-speed application versus low-shear storage. Formulators must characterize fluids across a wide range of shear rates to predict real-world performance. A coating that appears viscous in the can must often thin significantly to pass through a spray nozzle or flow off a brush.

This non-Newtonian behavior is typically characterized as pseudoplasticity or shear-thinning. Manufacturers use rotational rheometers to generate flow curves that map viscosity against shear rate. These curves reveal how the material responds to the specific mechanical forces encountered during manufacturing and use.

Understanding these profiles helps prevent issues during the pumping and filling process. High viscosity at medium shear rates can strain transfer pumps or slow down production lines. Conversely, viscosity that drops too precipitously might lead to excessive atomization or splashing during mixing.

Table 1: Typical shear rates encountered in coating processes.

Process | Approximate Shear Rate (s⁻¹) | Rheological Relevance |

|---|---|---|

Sedimentation | 0.0001 – 0.01 | Storage stability and shelf life |

Leveling / Sagging | 0.01 – 1 | Finish quality and film build |

Mixing / Stirring | 10 – 100 | Manufacturing efficiency |

Brushing / Rolling | 1,000 – 5,000 | Application feel and drag |

Spraying | 10,000 – 1,000,000 | Atomization and transfer efficiency |

Laboratory protocols often reference standards such as ASTM D4287 for high-shear viscosity. Compliance with ISO 3219 ensures consistent geometry and measurement conditions across different facilities. These standards provide a baseline for comparing the flow profiles of competitive products.

Why thixotropy determines application and recovery

Thixotropy quantifies the time-dependent structural recovery of a coating after the shear stress of application is removed. Unlike simple shear-thinning, which is instantaneous, thixotropic materials require a finite time to rebuild their internal network. This property is crucial for balancing leveling with sag resistance.

When a paint is applied to a vertical surface, gravity acts on the wet film immediately. If the structure recovers too quickly, brush marks or roller stipple may remain frozen in the finish. If recovery is too slow, the coating will run or sag before it sets.

Rheologists measure this behavior using three-step shear protocols or thixotropic loop tests. The three-step test simulates the resting state, the high-shear application, and the post-application recovery. This data allows formulators to tune the breakdown and buildup of rheological modifiers.

- Step 1: Low shear measures the baseline viscosity at rest.

- Step 2: High shear simulates the breakdown during spraying or brushing.

- Step 3: Low shear monitors the rate at which viscosity returns to the baseline.

Optimizing thixotropy ensures the coating stays on the wall while flowing out just enough to create a smooth surface. Excessively thixotropic paints may feel "false-bodied" in the can but fail to hide surface imperfections. Insufficient thixotropy leads to messy application and poor film build.

A comprehensive review titled "Applied rheology and architectural coating performance" in the Journal of Coatings Technology and Research emphasizes the importance of accurate thixotropic profiling over simple indices. These detailed measurements provide critical data on recovery speed and structure buildup. Tracking these parameters helps Quality Control (QC) labs maintain batch-to-batch consistency and predict application performance.

Measuring yield stress for storage stability and sag resistance

Yield stress represents the minimum force required to initiate flow in structured industrial coatings and paints. This parameter is the primary predictor of a coating's ability to resist sedimentation during long-term storage. Without sufficient yield stress, heavy pigments and fillers will settle to the bottom of the container.

Measuring yield stress requires sensitive rheometers capable of applying controlled stress ramps. The instrument gradually increases the stress until the material's internal structure fractures and flow begins. This transition point is the yield stress value.

High yield stress contributes to the "body" or gel-like appearance of a paint in the container. It prevents the hard-packing of aggregates that makes re-dispersion difficult or impossible. However, the yield stress must not be so high that it prevents proper leveling after application.

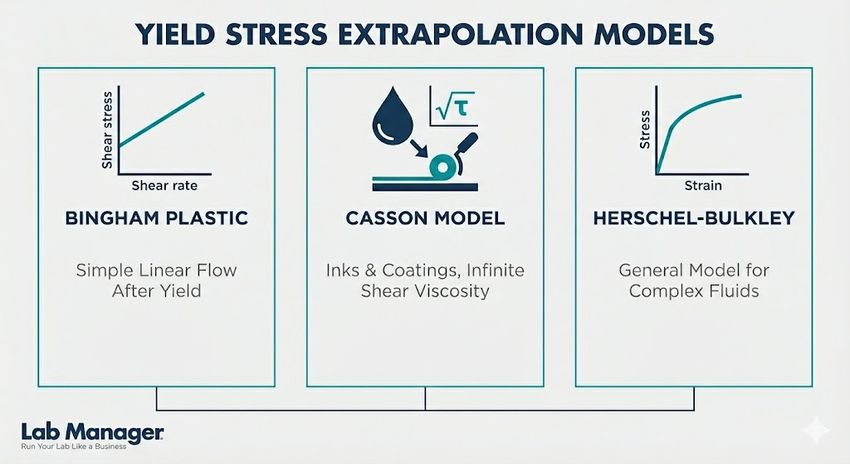

Mathematical models are frequently used to extrapolate yield stress from flow data. Common models include:

When extrapolating yield stress from flow data, choosing the right mathematical model is critical for accuracy.

GEMINI (2026)

- Bingham Plastic: Simple model for materials with a linear flow after yield.

- Casson Model: Often used for inks and coatings to estimate infinite shear viscosity.

- Herschel-Bulkley: Comprehensive model accounting for non-linear flow and yield stress.

Accurate yield stress determination is critical for formulating high-solids coatings. These formulations rely on dense particle packing and require precise rheological control to remain stable. Errors in this measurement can lead to costly product recalls due to separation or settling.

How temperature impacts curing profiles and viscosity

Temperature fluctuations significantly alter the viscosity and cure rate of industrial coatings and paints during processing and application. Viscosity typically decreases as temperature rises, following an Arrhenius relationship in uncured binders. Lab professionals must characterize this thermal dependency to ensure application equipment is set correctly.

In thermosetting coatings, temperature initiates the cross-linking reaction. A rheometer equipped with a temperature control unit can track the viscosity minimum and the subsequent onset of gelation. This "cure profile" defines the processing window for powder coatings and heat-cured enamels.

Cold environments pose distinct challenges for architectural and industrial maintenance paints. Low temperatures increase viscosity, making pumping difficult and hindering proper atomization. Rheological testing at low temperatures helps formulators add coalescing agents or adjust solvents to maintain workability.

Dynamic Mechanical Analysis (DMA) is often employed to study the cured film properties. This technique measures the storage modulus and loss modulus as a function of temperature. It identifies the glass transition temperature (Tg), which dictates the flexibility and impact resistance of the final coating.

Monitoring the chemorheology of curing systems prevents application failures in the field. If a coating gels too quickly in a hot spray line, it can clog equipment. If it cures too slowly, it may pick up contaminants or run off the substrate.

Selecting rheometer geometries for accurate coating data

Selecting the correct rheometer geometry ensures accurate characterization of industrial coatings and paints containing fillers or volatile solvents. The physical gap and shape of the measuring system must accommodate the specific nature of the sample. Using inappropriate geometry can lead to data artifacts like wall slip or particle jamming.

Cone and plate geometries are standard for homogenous coatings with fine particle sizes. They provide a uniform shear rate across the entire sample, simplifying data analysis. However, large aggregates in primers or textured coatings can bridge the small truncation gap, causing erroneous results.

Parallel plate geometries offer adjustable gaps to accommodate larger particles. They are versatile but require corrections for the shear rate gradient across the radius of the plate. This geometry is often preferred for temperature ramps and curing studies where sample expansion might occur.

Concentric cylinder systems (cup and bob) are ideal for low-viscosity fluids and samples prone to evaporation. The larger surface area provides excellent sensitivity for measuring yield stress and low-shear viscosity. Solvent traps or covers are essential accessories to prevent skinning during longer tests.

- Cone and Plate: Best for high-shear flow curves; requires small sample volume.

- Parallel Plate: Accommodates particulates; good for gap-dependent testing.

- Concentric Cylinder: Ideal for low-viscosity fluids; effective for controlling evaporation.

Regular calibration of these geometries is mandated by ISO and ASTM standards. Wear on the measuring surfaces or damage to the cone tip can significantly skew viscosity readings. Laboratories must implement strict cleaning protocols to prevent cross-contamination between solvent-based and water-based samples.

Modifying rheology with additives

Rheology modifiers are specialized additives introduced to industrial coatings and paints to precisely tailor flow behavior and stability. These additives, which include associative thickeners like HEUR (Hydrophobically modified Ethoxylated Urethane) and HASE (Hydrophobically modified Alkali Swellable Emulsions), interact with the binder and solvent network to build viscosity and control thixotropy. Incorporating clay-based additives or fumed silica is effective for increasing low-shear viscosity and yield stress, which directly improves sag resistance and storage stability. Formulators must carefully balance the dosage of these modifiers, as an overdose can negatively impact gloss, water resistance, and leveling. Verification involves running frequency sweep tests to analyze the viscoelastic response, ensuring the additive network provides the necessary elasticity without compromising the coating's final aesthetic and protective properties.

Optimizing industrial coating formulations with rheology

Consistent rheological testing empowers manufacturers to produce industrial coatings and paints that perform reliably in demanding environments. By mastering the relationships between shear rate, thixotropy, and yield stress, laboratories can predict application behavior and prevent common field failures. Rigorous adherence to standards like ASTM D4287 and the use of appropriate instrument geometries ensure data integrity. Ultimately, a deep understanding of rheology translates to superior product stability, optimized processing efficiency, and higher-quality surface finishes.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.