Introduction

Fentanyl, a potent synthetic opioid, is widely used in research, toxicology, and pharmaceutical laboratories. While its clinical applications are well known, its high toxicity presents significant safety concerns for laboratory personnel. Even minimal exposure can lead to accidental overdoses, making fentanyl safety a critical issue for modern lab environments.

In light of its potency—estimated to be 50–100 times stronger than morphine—fentanyl requires specialized protocols and infrastructure to protect lab personnel. This includes stringent handling procedures, meticulous storage protocols, and the use of appropriate personal protective equipment (PPE). With the increased use of fentanyl analogs in forensic and pharmacological research, fentanyl safety considerations have become more urgent and complex.

This article outlines the essential components of a comprehensive fentanyl safety strategy, with guidance rooted in compliance, risk mitigation, and operational best practices.

Implementing Effective Fentanyl Handling Protocols

Labs that handle fentanyl must implement precise operational procedures to minimize contact and inhalation risks. Standard operating procedures (SOPs) should be tailored to fentanyl's unique pharmacological profile and integrate fentanyl safety standards.

Core Handling Guidelines:

- Work in designated areas: Handle fentanyl in designated, clearly marked spaces with limited access.

- Use containment systems: Employ ventilated enclosures, such as fume hoods or glove boxes, to contain airborne particles.

- Minimize physical transfer: Whenever possible, use closed-system devices to reduce manual handling.

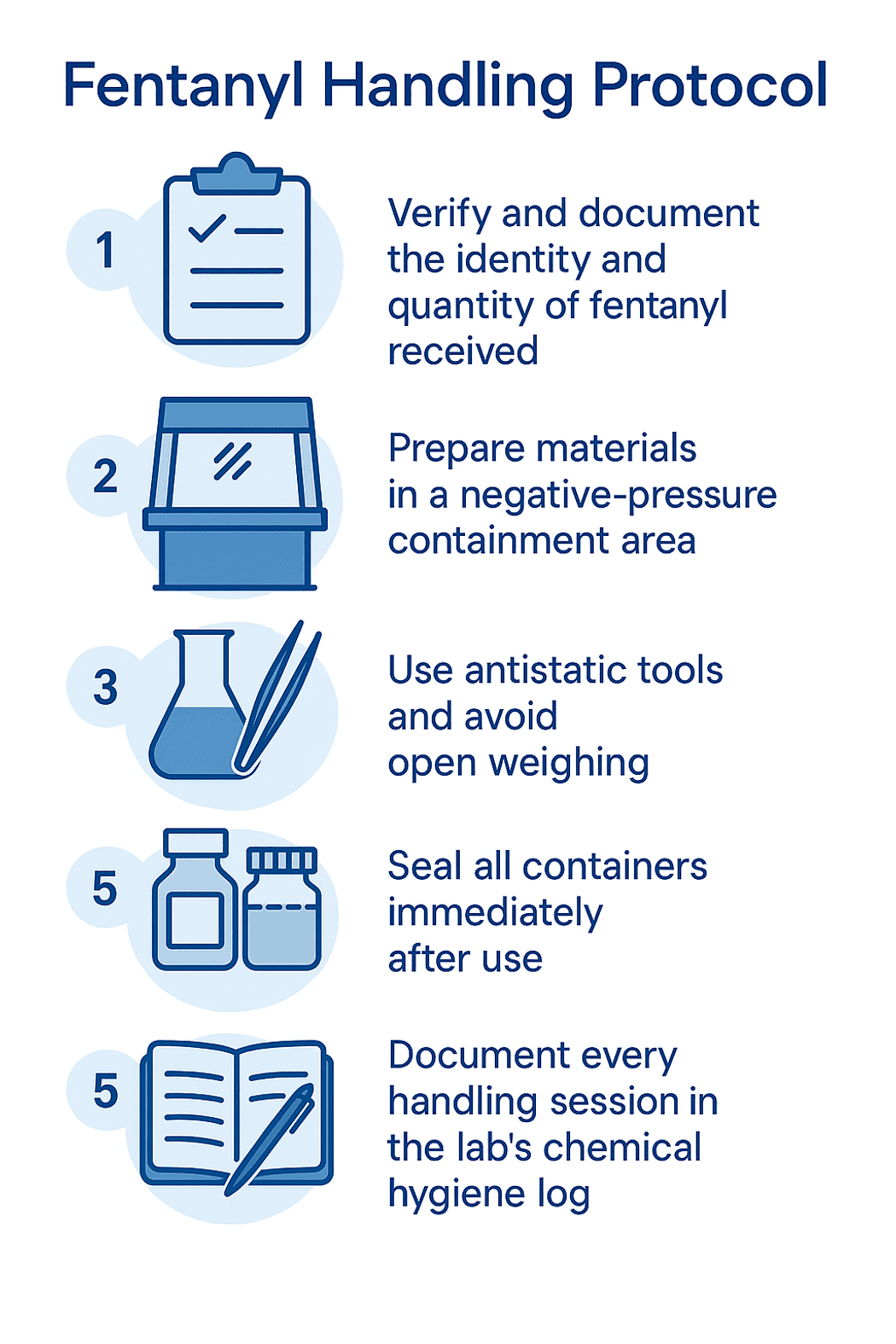

Step-by-Step Handling Protocol:

Fentanyl Handling Protocol

OpenAI (2025)

Verify and document the identity and quantity of fentanyl received: This ensures traceability and prevents the unintentional use of incorrect or mislabeled substances. Verifying source and quantity is the foundation for compliance with controlled substance regulations and inventory accuracy.

Prepare materials in a negative-pressure containment area: Working in a fume hood or glovebox with negative airflow prevents aerosolized fentanyl particles from escaping into the surrounding environment. This containment is essential to protect lab personnel from inhalation exposure.

Use antistatic tools and avoid open weighing: Fentanyl powders can become airborne easily due to static charge or air currents. Using antistatic tools and closed weighing systems minimizes the risk of particle dispersion, reducing both inhalation and contact hazards.

Seal all containers immediately after use: Preventing the spread of fentanyl dust or vapors is critical. Promptly sealing containers helps maintain lab air quality, avoid contamination of other surfaces, and ensures accurate inventory control.

Document every handling session in the lab’s chemical hygiene log: Accurate recordkeeping supports regulatory compliance and internal accountability. Logs help track usage patterns, flag potential losses, and provide a clear history in case of an audit or incident investigation.

Real-world application: In forensic toxicology labs, fentanyl is often analyzed as part of controlled substance testing. Labs have reported success using powder-tight microbalances and disposable spatulas within ductless enclosures to ensure fentanyl safety during sample prep.

PPE Requirements: Dressing for Fentanyl Safety

Proper PPE is essential to avoid exposure through skin contact, inhalation, or accidental ingestion. Unlike many laboratory chemicals, even dermal exposure to fentanyl can be life-threatening. Fentanyl safety protocols mandate specific PPE combinations for maximum protection.

Recommended PPE for Fentanyl Work:

| PPE Item | Purpose | Notes |

|---|---|---|

| Nitrile Gloves (double) | Protect against dermal exposure | Change every 30 minutes or if torn |

| Disposable Gown or Tyvek Suit | Full body coverage | Ensure cuffed sleeves to prevent gaps |

| N95 or P100 Respirator | Protect from inhalation of powders | Fit-tested annually for optimal safety |

| Safety Goggles | Eye protection from splashes or dust | Should wrap around sides |

| Boot Covers | Prevent floor contamination | Dispose after single use |

Glove compatibility is particularly important. Labs are encouraged to consult chemical compatibility charts to ensure fentanyl resistance in the selected glove material.

💡 Tip: Labs conducting high-volume analyses often rotate PPE stock biweekly and perform random audits to ensure full compliance with fentanyl safety standards.

Secure Storage and Inventory Control for Fentanyl Safety

Fentanyl must be stored with the same rigor as other DEA Schedule II substances. Beyond legal compliance, proper storage is a frontline defense against both accidental exposure and unauthorized access, ensuring fentanyl safety is maintained.

Storage Best Practices:

- Locked Cabinets: Use DEA-compliant, double-locked storage units anchored to lab walls or floors.

- Segregation: Store fentanyl separately from incompatible substances such as strong oxidizers.

- Temperature and Humidity Control: Maintain stable storage conditions to preserve chemical integrity.

- Labeling: Ensure all containers are labeled with hazard pictograms and concentration details.

Inventory Tracking Table:

| Requirement | Implementation Example |

| Real-time tracking | Use digital inventory systems like SciShield's ChemTracker Software |

| Chain-of-custody logging | Record every withdrawal with time and personnel ID |

| Regular auditing | Schedule quarterly reconciliations |

Institutions conducting audits have found digital inventory platforms reduce fentanyl discrepancies by 35% compared to paper logs, strengthening both security and fentanyl safety accountability.

Emergency Response and Spill Management

Even with preventive protocols, accidental spills or exposures can occur. A fentanyl-specific emergency response plan should be in place and rehearsed regularly to ensure comprehensive fentanyl safety.

Key Elements of a Response Plan:

- Immediate area evacuation: Non-essential personnel must leave the area during a spill.

- Use of spill kits: Stock opioid-specific spill kits with absorbent pads, PPE, and naloxone.

- Decontamination: Surfaces should be cleaned with soap and water; avoid bleach, which may aerosolize powders.

- Medical attention: Exposed personnel should be evaluated immediately, even if symptoms are not present.

- Incident reporting: Log and review all incidents to improve SOPs and training.

Supporting Example: A research facility that experienced a minor fentanyl spill successfully contained it within five minutes using pre-stocked spill kits, preventing exposure and maintaining fentanyl safety.

Training, Compliance, and Cultural Integration

Safety in fentanyl handling is not solely a technical issue—it is cultural. Ensuring long-term compliance requires ongoing training, leadership support, and integration into the lab’s fentanyl safety culture.

Training Essentials:

- Conduct hands-on drills for spill response: Schedule quarterly training simulations to reinforce rapid response actions for fentanyl exposure. For example, one university-affiliated lab uses scenario-based drills involving mock spills and naloxone administration to test team readiness.

- Provide annual respirator fit tests and PPE training: Partner with occupational health services to ensure all lab staff undergo fit testing for N95 or P100 respirators. Incorporate practical sessions where personnel don full PPE and simulate sample preparation under supervision.

- Include fentanyl-specific modules in onboarding programs: Develop e-learning courses or workshops tailored to fentanyl safety, covering chemical properties, exposure risks, and emergency protocols. The Centre for Addiction and Mental Health (CAMH) in Toronto mandates completion of a two-hour fentanyl safety module as part of its chemical safety training program before personnel are granted access to restricted substances.

Building a Culture of Fentanyl Safety:

- Recognize safety champions who demonstrate exemplary practices: Establish monthly or quarterly awards for staff who uphold best practices. Highlight their contributions during team meetings or in lab newsletters to reinforce a positive safety culture.

- Encourage anonymous reporting of safety concerns: Implement a digital safety reporting system where employees can share incidents or near-misses without fear of reprisal. Anonymous feedback has led several institutions to refine their PPE storage systems after identifying bottlenecks.

- Integrate safety KPIs into lab performance metrics: Align safety with performance reviews by including adherence to fentanyl safety protocols, participation in training, and proactive risk reporting. This promotes accountability and embeds safety into daily operations.

By institutionalizing these practices, labs can significantly reduce risks and ensure that fentanyl-related operations meet both ethical and regulatory expectations.

Conclusion

The potency of fentanyl makes it both a powerful research tool and a dangerous laboratory hazard. By adopting best practices in handling, PPE use, storage, and emergency response, laboratories can effectively mitigate the risks associated with this compound. More importantly, fostering a fentanyl safety-first culture ensures that protocols are not just followed, but owned by every team member.

As fentanyl use in research and forensic applications expands, labs that prioritize proactive fentanyl safety strategies will be better positioned to comply with regulations, protect personnel, and maintain operational integrity.

Frequently Asked Questions (FAQ)

Q1: Why is fentanyl more dangerous to handle than other lab chemicals?

Fentanyl is extremely potent and can be absorbed through the skin or inhaled in very small quantities, potentially leading to overdose. This high toxicity requires enhanced safety measures, even compared to other controlled substances.

Q2: What should I do if I suspect exposure to fentanyl in the lab?

Immediately follow your lab's emergency response protocol, which should include evacuating the area, alerting trained personnel, administering naloxone if necessary, and seeking medical attention.

Q3: Is a standard lab coat and gloves sufficient when handling fentanyl?

No. Fentanyl safety protocols require more comprehensive PPE, including double nitrile gloves, Tyvek suits, and a fit-tested N95 or P100 respirator. These measures minimize the risk of skin contact and inhalation.

Q4: How often should fentanyl handling protocols and training be reviewed?

At minimum, training should be reviewed annually. However, labs working regularly with fentanyl may conduct quarterly drills and revise protocols based on incident reports or regulatory updates.

Further Resources

- NIOSH: Fentanyl: Preventing Occupational Exposure

- DEA Diversion Control Division – Fentanyl Safety Recommendations

- American Industrial Hygiene Association (AIHA): Guidance for Responders