Artificial intelligence is increasingly reshaping how laboratories model complex material systems. A new finding from researchers at Chungnam National University shows how AI defect prediction in liquid crystals can replace slow numerical simulations with rapid, data-driven modeling.

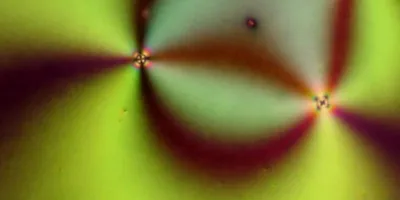

Topological defects are stable irregularities that emerge when symmetry breaks during phase transitions. In materials science, these defects strongly influence mechanical, optical, and electronic properties. In liquid crystals, defect formation affects molecular alignment, light propagation, and device performance, making defect control a central challenge for laboratories working in soft matter and optical materials.

Traditional modeling of liquid crystal defects relies on computationally intensive simulations that can take hours to reach equilibrium. By contrast, AI defect prediction in liquid crystals offers laboratories a faster way to analyze defect behavior, explore design options, and reduce computational bottlenecks in materials research workflows.

Why liquid crystal defects matter in materials science

Nematic liquid crystals are a widely studied class of soft materials in which molecules rotate freely while maintaining partial directional order. This unique behavior allows researchers to observe how liquid crystal defects form, move, and reorganize under different boundary conditions.

Defect structures in nematic liquid crystals are commonly described using the Landau–de Gennes theory, which explains how molecular order collapses inside defect cores. While accurate, this approach requires solving complex numerical equations, limiting how many configurations laboratories can realistically explore.

For materials science laboratories, understanding liquid crystal defects is critical for designing optical materials, metamaterials, and responsive systems where defect placement and stability directly affect performance.

AI defect prediction replaces slow simulations

The research team introduced a deep learning framework specifically designed for AI-based defect prediction in liquid crystals. Instead of performing step-by-step simulations, the model maps boundary conditions directly onto the final equilibrium molecular alignment field.

The system is built using a three-dimensional U-Net architecture, a convolutional neural network commonly applied in scientific image analysis. This structure enables the model to capture both large-scale molecular alignment and fine-scale defect features within a single prediction.

After training on datasets generated from traditional simulations, the model accurately predicted new defect configurations it had not previously encountered. Predictions that once required hours of computation were produced in milliseconds, dramatically improving modeling efficiency for laboratory workflows.

“Our approach complements slow simulations with rapid, reliable predictions, facilitating the systematic exploration of defect-rich regimes,” said professor Jun-Hee Na.

Modeling complex and merging liquid crystal defects

A key strength of the approach is its ability to model complex defect behavior without relying on explicit physical equations. Instead, the system learns material behavior directly from data, enabling it to capture higher-order and dynamic interactions among defects.

The model successfully handled cases in which liquid crystal defects merge, split, or annihilate—scenarios that are particularly difficult to resolve using conventional simulation methods. Experimental validation confirmed that the AI predictions closely matched both simulation results and laboratory observations across a wide range of conditions.

For laboratory managers, this capability reduces reliance on specialized computational expertise and supports more flexible materials science AI modeling strategies.

Implications for laboratory operations and materials design

By accelerating AI defect prediction in liquid crystals, the approach enables laboratories to screen more material configurations, shorten development cycles, and reduce experimental trial-and-error. Computational modeling can be used earlier and more often in the research process, guiding physical experiments toward the most promising designs.

The researchers highlight applications in advanced optical materials, metamaterials, and adaptive systems, including smart windows, adaptive optics, and holographic and AR/VR display technologies.

For lab leaders, the work demonstrates how materials science AI modeling can move beyond data analysis into core simulation tasks, reshaping how laboratories balance computation, experimentation, and materials design.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.