Introduction: Understanding the Role of Fume Hoods in Laboratory Environments

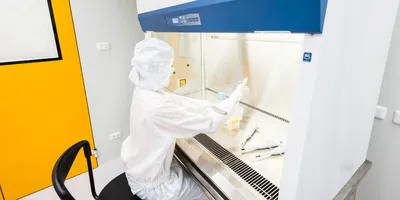

A fume hood is a critical component in laboratory safety infrastructure, designed to limit exposure to hazardous or toxic fumes, vapors, or dust. This ventilated enclosure captures and expels airborne contaminants generated during chemical processes. Given the array of volatile chemicals used in research and industrial labs, fume hoods serve as a frontline defense to ensure occupational safety and maintain air quality.

Laboratory professionals must navigate a complex array of containment systems, including chemical fume hoods, ductless fume hoods, and biosafety cabinets. Each tool has distinct applications and technical specifications. Understanding these differences is essential to implementing effective lab safety protocols and ensuring regulatory compliance.

How Fume Hoods Work: Principles and Components

Airflow Mechanics

At the core of a fume hood's operation is a consistent flow of air that draws hazardous particles away from the user. This is typically achieved through:

- Face velocity: The speed at which air is drawn into the hood, measured in feet per minute (fpm). Optimal performance usually ranges between 80 to 120 fpm.

- Sash design: Movable glass panels help control airflow and provide physical separation between the operator and hazardous materials.

- Exhaust system: In ducted models, contaminated air is expelled outdoors via ducts, ensuring that no recirculation occurs within the lab.

Filters and Monitoring

In ductless fume hoods, filters—usually activated carbon or HEPA filters—trap and neutralize contaminants before recirculating clean air back into the lab. These units are equipped with sensors to monitor filter saturation and airflow efficiency.

Types of Fume Hoods and Their Applications

Chemical Fume Hoods

These are the most commonly used fume hoods in research and industrial settings. They are designed to handle a wide range of chemical processes involving acids, bases, and volatile solvents.

Common features include:

- Ducted exhaust to the exterior

- Adjustable sash for user protection

- Epoxy resin work surface for chemical resistance

Applications:

- Organic synthesis

- Acid digestion

- Solvent evaporation

Ductless Fume Hoods

These hoods are equipped with filtration systems that clean the air before recirculating it back into the room. They are often chosen for:

- Mobility: Can be relocated easily due to the absence of ductwork.

- Cost-efficiency: Lower installation costs and energy consumption.

- Specialized use: Ideal for low-risk procedures or use in educational settings.

Limitations:

- Limited to specific chemicals

- Requires frequent filter replacement

Biosafety Cabinet vs Fume Hood

While often confused, these two systems serve distinct purposes:

| Feature | Fume Hood | Biosafety Cabinet |

|---|

| Purpose | Protects user from chemical exposure | Protects user, product, and environment from biological agents |

| Airflow | Exhausts air (ducted or filtered) | Recirculates HEPA-filtered air inside cabinet |

| Applications | Chemical handling | Microbiological work, cell culture |

| Filtration | Carbon/HEPA filters (ductless) | HEPA filters only |

A fume hood is primarily used to contain and remove chemical vapors, dust, and fumes during laboratory procedures. Its airflow direction is unidirectional, pulling contaminants away from the user and venting them outside the building or through filters in ductless variants.

In contrast, a biosafety cabinet (BSC) is engineered for work involving biological materials, especially infectious agents. It not only protects the user but also the research material and surrounding environment by using HEPA filtration and controlled airflow patterns.

There are several types of BSCs, including:

- Class I: Protects the user and the environment, but not the sample

- Class II: Offers protection for user, environment, and sample

- Class III: Gas-tight enclosure for maximum containment

Choosing between the two depends entirely on the nature of the work:

- If you're handling hazardous chemicals, a fume hood is essential.

- If your focus is on microbiological research or sterile technique, a biosafety cabinet is the correct choice.

Understanding these differences is crucial when selecting containment systems for specific lab protocols, ensuring both safety and experimental integrity.

Tools and Technologies for Fume Hood Efficiency

Smart Fume Hoods

Modern systems integrate IoT sensors and digital interfaces to enhance safety and efficiency. Features include:

- Airflow sensors that alert users when face velocity falls below safe levels

- Auto sash controllers to reduce energy usage when not in use

- Remote monitoring for facility-wide safety oversight

Energy-Efficient Models

Given the high operational costs of ducted systems, newer models aim to reduce energy consumption through:

- Variable air volume (VAV) systems

- Night setback modes

- High-performance filters with longer lifespans

Maintenance Tools

Regular testing and certification are vital for performance. Technicians often use:

- Anemometers to measure face velocity

- Smoke generators to visualize airflow

- Digital flow meters for precision diagnostics

Safety Standards and Compliance

Fume hoods must comply with established safety standards, including:

- ASHRAE 110: Standard for testing performance of laboratory fume hoods

- OSHA regulations: Requirements for hazardous chemical handling

- NFPA 45: Fire protection standards for laboratories

Following these guidelines ensures the safety of personnel and the integrity of research outcomes.

Choosing the Right Fume Hood: Factors to Consider

Selecting the appropriate fume hood requires a nuanced understanding of laboratory needs and safety requirements. Several key factors must be weighed to ensure effective and compliant containment:

- Chemical Compatibility: Determine the types of chemicals and solvents that will be handled. For example, a lab working with strong acids like hydrochloric acid or volatile organics like acetone should prioritize chemical fume hoods with corrosion-resistant linings and high-capacity airflow.

- Air Handling System: Assess whether your facility supports ducted ventilation. In cases where ductwork is impractical or cost-prohibitive, a ductless fume hood with appropriate filtration may be a suitable alternative, provided it meets the chemical compatibility criteria.

- Space and Mobility Requirements: Labs with limited space or changing layouts may benefit from portable or benchtop ductless fume hoods. For instance, educational labs or temporary research projects often require equipment that can be moved or reconfigured easily.

- Regulatory Compliance: Ensure the fume hood adheres to relevant standards such as ASHRAE 110, OSHA regulations, and NFPA 45. For biosafety applications, additional CDC and NIH guidelines may apply. Compliance is essential not just for safety, but also for passing inspections and maintaining accreditation.

- Budget Constraints: Balance upfront installation costs with long-term operational expenses. Ducted systems may have higher installation costs but lower ongoing filter maintenance, while ductless hoods can be cheaper to install but require regular filter replacement. Consider total cost of ownership, including energy usage, maintenance, and certification.

Ultimately, a comprehensive risk assessment—taking into account chemical use, user habits, space constraints, and compliance standards—should guide the final selection and setup of your laboratory fume hood system.

Conclusion: Fume Hood Safety Insights for Modern Laboratory Protection

Fume hoods are indispensable for ensuring laboratory safety, minimizing exposure to toxic substances, and maintaining regulatory compliance. Whether opting for a traditional chemical fume hood, a ductless model, or navigating the decision of biosafety cabinet vs fume hood, understanding each option's functionality and limitations is critical.

By leveraging modern technologies, adhering to safety standards, and conducting routine maintenance, laboratory professionals can optimize containment strategies and safeguard both personnel and experimental integrity. As research demands evolve, so too must our approach to lab safety infrastructure.

Frequently Asked Questions (FAQ)

What is the difference between a fume hood and a biosafety cabinet?

A fume hood protects users from chemical fumes by exhausting air from the lab, while a biosafety cabinet also protects the product and environment using HEPA-filtered, recirculated air, ideal for biological work.

Are ductless fume hoods safe for handling all chemicals?

No. Ductless fume hoods are only suitable for specific chemicals and low-risk procedures. They rely on filters that must be chosen based on the substances in use and replaced regularly.

How often should a fume hood be tested or certified?

Fume hoods should be tested and certified at least annually according to ASHRAE 110 standards or more frequently if lab protocols dictate increased usage or exposure.

What are the most energy-efficient features of modern fume hoods?

Smart features like variable air volume (VAV), auto sash positioning, and night setback modes help reduce energy consumption while maintaining safety and airflow standards.