The increasing complexity of industrial materials used in critical applications—from aerospace components to medical devices—necessitates rigorous and documented validation practices. Laboratory professionals in materials science labs and QA/QC environments are tasked with proving that both the materials themselves and the analytical methods used to characterize them are fit for their intended purpose. Establishing and maintaining a robust validation framework is the cornerstone of material reliability (e.g., as formalized in standards like ASTM E2500), ensuring that every batch and component meets stringent specifications and contributes to the final product's quality, safety, and performance. This commitment to meticulous material and method validation minimizes operational risk and upholds the highest standards of regulatory compliance.

Establishing foundational principles for industrial materials validation

The starting point for material assurance is a clear understanding of the principles governing validation and material qualification. Validation, in this context, refers to establishing documented evidence that provides a high degree of assurance that a specific process, method, or system consistently produces a result meeting predetermined specifications and quality attributes. For industrial materials, this extends beyond standard equipment calibration to encompass the entire analytical lifecycle.

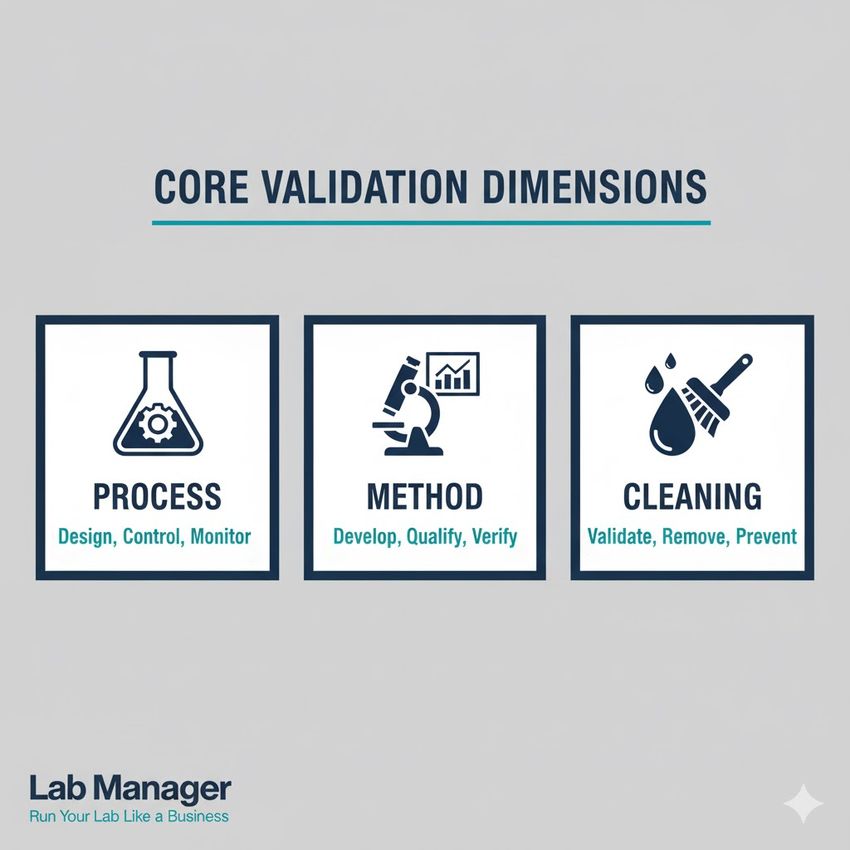

The primary objective is to demonstrate with certainty that an industrial material possesses the necessary properties for its end-use. This is achieved through a structured approach that includes three core validation dimensions:

Process, Method, and Cleaning—the three pillars of a validated laboratory.

GEMINI (2025)

- Process validation: Confirming that the manufacturing process of the material consistently yields a product meeting all predefined quality attributes (e.g., composition, purity, crystalline structure).

- Method validation (analytical procedure validation): Proving that the testing methods employed in the materials science labs accurately and reliably measure the critical quality attributes (CQAs) of the material. Guidance from bodies such as the International Council for Harmonisation (ICH) Q2(R2). provides the most current global standards for analytical validation and development, covering parameters like specificity, accuracy, precision, linearity, and robustness.

- Cleaning validation: Ensuring that any equipment or vessel used to handle the industrial materials is cleaned effectively to prevent cross-contamination, which is particularly critical in QA/QC labs handling different material grades or formulations.

A successful materials validation strategy relies heavily on the use of traceable reference materials and meticulous documentation to create an audit trail supporting the integrity of the material data. This structured approach allows QA/QC specialists to transition from simply testing for compliance to proactively managing material quality risks.

Implementing qualification protocols: IQ, OQ, and PQ for testing systems

To ensure that analytical results are trustworthy, the instruments and systems generating the data must undergo formal qualification, a key step in validation protocols. This systematic approach, typically known as Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ), verifies the suitability of the testing equipment used for the analysis of industrial materials.

Phase | Description | Key Deliverables |

|---|---|---|

Installation Qualification (IQ) | Confirms that the instrument is received, installed, and configured according to the manufacturer's and laboratory's design specifications. | Verification of utility connections, confirmation of software installation, and documentation of all serial numbers and component lists. |

Operational Qualification (OQ) | Verifies that the instrument operates as intended throughout its anticipated operating range under defined conditions. | Testing of all functional parameters (e.g., temperature control, flow rate, detector response) to ensure performance meets established acceptance criteria. |

Performance Qualification (PQ) | Demonstrates that the instrument consistently performs according to defined specifications for its routine operational use in the materials science labs. | Long-term, routine testing using certified reference materials and real-world samples to confirm system suitability and data accuracy over time. |

The execution of these qualification protocols is essential for the continuous assurance of measurement accuracy, especially when testing properties like tensile strength, viscosity, or chemical composition of complex industrial materials. The completion of OQ and PQ activities provides the necessary evidence that the equipment is suitable for use before any analytical method validation begins. This system-level qualification is a fundamental requirement for laboratories operating under current Good Manufacturing Practices (cGMP) or ISO standards (e.g., ISO/IEC 17025).

Risk assessment and the lifecycle approach to validation

A modern approach to validation for industrial materials utilizes a lifecycle model heavily informed by quality risk management principles. Quality risk management involves the systematic process of assessing, controlling, communicating, and reviewing risks to the quality of the material throughout its lifecycle. This ensures that the effort and rigor of validation are commensurate with the level of risk posed by the material's potential failure or non-compliance.

The risk assessment process applied in materials science labs typically includes these steps:

- Material criticality assessment: Identifying the critical quality attributes (CQAs) of the industrial material and determining the potential impact of CQA variation on the final product’s performance or safety. A high-risk material (e.g., a structural alloy in an aircraft) requires the most extensive validation.

- Analytical method risk: Evaluating the inherent variability and complexity of the analytical method being validated. Methods relying on complex sample preparation or subtle instrument adjustments carry higher risk and require more comprehensive method validation studies (e.g., greater focus on robustness).

- Control strategy development: Implementing control mechanisms—including enhanced sampling plans, tighter acceptance criteria, and increased frequency of system suitability checks—to mitigate identified risks.

This lifecycle approach mandates that validation is not a one-time event but a continuous process. Regular re-validation or periodic review is necessary whenever significant changes occur (e.g., changes in the material supplier, manufacturing location, analytical equipment, or method validation parameters). Proactive risk assessment ensures that laboratory resources are focused on the most critical testing challenges, maintaining the quality of industrial materials consistently. (Refer to ISO 31000 for foundational guidance on risk management principles)

Documentation and regulatory compliance in materials science validation

Effective validation is inseparable from thorough documentation. The documentation generated during the qualification and validation phases serves as the primary evidence of compliance for regulatory bodies and internal QA/QC audits. A well-defined Standard Operating Procedure (SOP) structure ensures that the execution, recording, and reporting of all industrial materials testing are standardized and repeatable.

The essential documentation elements for materials validation include:

- Validation master plan (VMP): A high-level document outlining the laboratory’s overall validation strategy, scope, responsibilities, and acceptance criteria for all major equipment and analytical methods.

- Validation protocols: Detailed, pre-approved documents specifying the test parameters, acceptance criteria, testing procedure, and deviation handling for a specific method or piece of equipment.

- Validation reports: The final, signed documents that present the raw data, summarize the results against the predefined acceptance criteria, and formally conclude whether the method or equipment is validated/qualified.

- Standard operating procedures (SOPs): Detailed, step-by-step instructions for the execution of the validated analytical method, ensuring that routine testing of industrial materials is performed exactly as proven during validation.

Compliance with regulatory standards—such as the Food and Drug Administration’s 21 CFR Part 11 for electronic records and signatures, or specific ASTM standards for material testing—is paramount in materials science labs. Accurate and contemporaneous documentation provides the defensible evidence needed to support material release decisions and is an absolute requirement for ensuring the trustworthiness of all data associated with industrial materials.

Sustaining quality: The continuous oversight of industrial materials

The continuous oversight of industrial materials requires more than initial validation; it demands a robust system for ongoing monitoring and re-validation. Periodic review of methods and equipment, trend analysis of material testing data, and comprehensive change control procedures are essential elements of maintaining compliance and preventing material failures. Sustained quality in QA/QC hinges on embedding validation into the daily operation of the laboratory, ensuring the integrity of industrial materials from receipt through final product deployment.

Frequently asked questions about industrial materials validation

What is the difference between calibration and validation in materials science labs?

Calibration is the process of comparing a measuring instrument's output to a known standard to confirm its accuracy. Validation is the broader process of establishing, through documented evidence, that the entire method, process, or system is consistently capable of producing a result that meets pre-determined quality specifications for industrial materials.

How often should analytical methods for industrial materials be revalidated?

Analytical method revalidation is not typically based on a set time interval but is instead triggered by significant changes. These changes include modifications to the material's manufacturing process, changes in critical reagents or instrumentation, or observed changes in the method's performance metrics that fall outside established criteria, necessitating further validation.

Which key analytical parameters must be validated for industrial materials testing?

The parameters required for method validation depend on the test's purpose (e.g., identification, impurity testing, or assay). Key parameters frequently validated in QA/QC labs include accuracy, precision (repeatability and intermediate precision), specificity, detection limit, quantitation limit, linearity, range, and robustness.

What is the role of change control in the validation of industrial materials?

Change control is a mandatory system that formally assesses the impact of any proposed change—to materials, equipment, or methods—on the validated state of the laboratory. It ensures that no change is implemented until it has been properly documented, assessed for risk, and, if necessary, accompanied by appropriate re-qualification or re-validation efforts.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.