The modern industrial landscape, from the high-octane thrust of a jet engine to the intense thermal environment of a power plant, relies on materials that can perform under the most unforgiving conditions. These specialized materials are not just a design choice; they are the fundamental enablers of technological progress. high-temperature alloys and a key subset, superalloys, represent a class of aerospace materials and other industrial components specifically engineered to maintain their mechanical integrity at extreme temperatures. Unlike conventional metals, which weaken and deform under heat, these heat-resistant alloys possess an exceptional ability to withstand stress, corrosion, and oxidation at temperatures that would cause others to fail. The development and continuous refinement of these extreme environment materials are crucial for advancing industries where efficiency and reliability are paramount. This article explores the metallurgical principles, applications, and future of these critical materials.

The Metallurgy of High-Temperature Alloys

The unique properties of high-temperature alloys are not accidental; they are the result of deliberate and sophisticated metallurgical design. The goal is to create a microstructure that resists the primary failure mechanisms at elevated temperatures, namely creep and oxidation. Creep is the slow, permanent deformation of a material under continuous stress at temperatures below its melting point, while oxidation is the reaction with oxygen that leads to material degradation.

To combat these phenomena, heat-resistant alloys utilize several strengthening mechanisms:

- Solid-Solution Strengthening: Alloying elements with different atomic radii (e.g., tungsten, molybdenum) are dissolved into the base metal's crystal lattice. This distorts the lattice, impeding the movement of dislocations and making the material stronger and more creep-resistant.

- Precipitation Hardening: Tiny, uniformly dispersed particles (precipitates) are formed within the alloy's matrix. These precipitates act as barriers to dislocation movement, significantly increasing the alloy’s strength at high temperatures. In nickel-based superalloys, the gamma-prime (γ′) phase is a classic example of this mechanism.

- Grain Boundary Strengthening: The boundaries between crystalline grains are critical points of weakness at high temperatures. By controlling the grain size and shape, particularly through techniques like directional solidification to create columnar or single-crystal structures, engineers can dramatically improve creep resistance and fatigue life.

The intricate combination of these mechanisms is what sets high-temperature alloys apart. The careful selection of alloying elements, from nickel and cobalt for the base to chromium and aluminum for oxidation resistance, allows for the precise tailoring of a material's properties for a specific demanding application.

Superalloys: The Apex of Extreme Environment Materials

Within the family of high-temperature alloys, a special class known as superalloys represents the pinnacle of performance. Primarily based on nickel, cobalt, or iron, these alloys are designed to withstand the most severe operating conditions, making them the most valuable of all extreme environment materials. Their development was a direct response to the demands of the jet age, where turbine blades needed to operate in temperatures hotter than the melting point of steel.

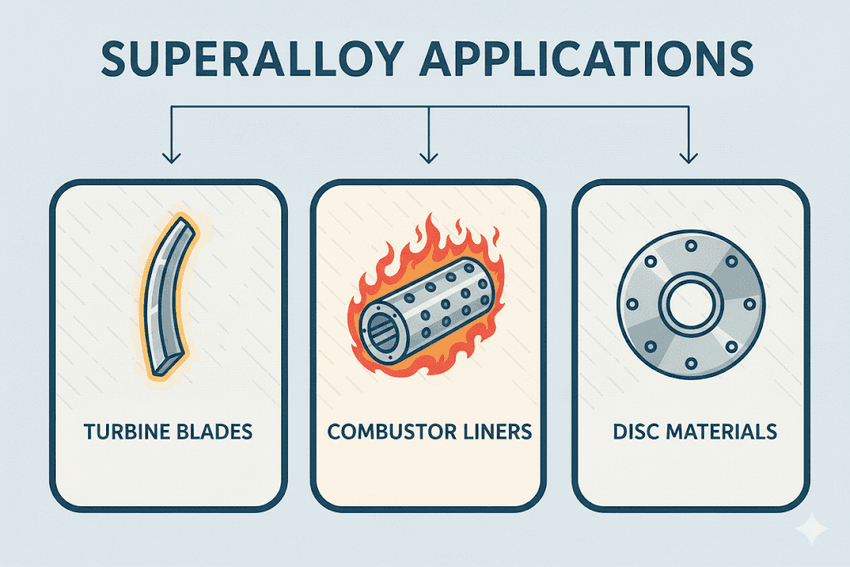

Nickel-based superalloys are particularly dominant in the aerospace industry. Their outstanding creep, fatigue, and corrosion resistance at temperatures up to 1200°C (2192°F) makes them the undisputed choice for critical engine components. The following components are almost exclusively made from these advanced aerospace materials:

Superalloys have a variety of applications in the aerospace industry.

GEMINI (2025)

- Turbine Blades and Vanes: Exposed to the highest temperatures and stresses in the engine. Superalloys allow for higher firing temperatures, which directly translates to improved fuel efficiency and thrust.

- Combustor Liners: The inner wall of the combustion chamber, which must contain the extreme heat and pressure of the burning fuel-air mixture.

- Disc and Shaft Materials: Although not as hot as the blades, these components must withstand immense centrifugal forces at elevated temperatures for the engine's lifetime.

The manufacturing of superalloys is a complex process involving vacuum induction melting, vacuum arc remelting, and often, sophisticated casting techniques like directional solidification and single-crystal growth. These processes ensure the material’s purity and a controlled microstructure, which is essential for achieving the required performance.

Beyond Aerospace: The Versatile Applications of Heat-Resistant Alloys

While the aerospace industry is the most prominent user, the properties of high-temperature alloys make them indispensable in a wide range of other sectors. Their ability to maintain strength and resist degradation in harsh thermal and corrosive environments extends their use to applications far beyond jet engines.

In power generation, heat-resistant alloys are critical for the efficiency and reliability of gas turbines used to generate electricity. The hotter the operating temperature, the greater the thermal efficiency of the turbine. Components such as turbine blades, shafts, and other hot section parts are made from superalloys to push the limits of power output. The nuclear power industry also relies on these materials for components within reactors that operate at high temperatures and pressures, such as heat exchangers and piping.

The chemical and petrochemical industries utilize extreme environment materials in processes involving corrosive fluids at elevated temperatures. Components like reactor vessels, catalysts, and furnace linings are often made from nickel-based heat-resistant alloys to prevent premature failure from chemical attack and thermal degradation. Even in the manufacturing of glass and steel, where materials are heated to extremely high temperatures, these alloys are used for molds, rollers, and other equipment that must not deform or fail.

The Future of High-Temperature Alloys

As industries continue to push the boundaries of performance and efficiency, the demand for ever-more capable high-temperature alloys will only grow. The focus of current research and development is on several key areas aimed at overcoming present limitations.

One major challenge is improving a material’s resistance to oxidation and hot corrosion. Protective coatings, such as thermal barrier coatings (TBCs), are increasingly used to shield the underlying alloy from the harsh environment, allowing it to operate at even higher temperatures. Researchers are also exploring novel alloy compositions, including refractory metal-based alloys, and new processing techniques to create more complex microstructures with enhanced properties. The continued development of single-crystal casting methods aims to eliminate grain boundaries entirely from critical components, further boosting creep resistance and fatigue life.

The integration of advanced manufacturing technologies, such as additive manufacturing (3D printing), is a transformative development. Additive manufacturing allows for the creation of intricate, lightweight geometries that are impossible to produce with traditional casting and forging methods. This enables the design of more efficient and complex components, further solidifying the role of superalloys as the core of future aerospace materials and other extreme environment materials. The future of high-temperature alloys lies in their ability to meet the unprecedented demands of the next generation of power systems, vehicles, and industrial processes.

Frequently Asked Questions About High-Temperature Alloys

What distinguishes superalloys from other high-temperature alloys?

Superalloys are a specialized subset of high-temperature alloys defined by their exceptional ability to withstand extreme stress, corrosion, and temperatures, often exceeding 1000°C. They are typically based on nickel, cobalt, or iron.

What is the primary failure mode that heat-resistant alloys are designed to resist?

The most significant failure mode for high-temperature alloys at elevated temperatures is creep, which is the slow, irreversible deformation of the material under constant stress. high-temperature alloys are engineered to have high creep resistance.

Where are these extreme environment materials most commonly used?

Extreme environment materials are most prevalent in the hot sections of jet engines and gas turbines, where they are used for components like turbine blades, combustor liners, and other critical parts. They are also used in power generation, chemical processing, and furnace equipment.

Why are single-crystal structures used for some superalloys components?

Single-crystal structures are used for certain superalloys components, such as turbine blades, to eliminate grain boundaries. This significantly enhances the material's creep resistance and fatigue life, allowing for operation at higher temperatures and stresses.