The relentless pursuit of innovation across sectors from electronics to defense is fundamentally reliant on the development and characterization of specialized materials. For the laboratory professional, these materials are not merely a subject of study but are integral to the very tools, standards, and methodologies that underpin modern scientific inquiry. The integrity, purity, and unique properties of a material directly influence the accuracy of analytical results, the reliability of experimental data, and the feasibility of groundbreaking research. Understanding the properties and applications of these materials is therefore essential for ensuring scientific rigor and advancing technological capabilities. This article explores the principles and applications of specialized materials that are shaping the landscape of scientific and industrial applications.

High-Purity Specialized Materials for Analytical Chemistry

In analytical chemistry, the adage "garbage in, garbage out" has profound implications. The very success of a quantitative or qualitative analysis hinges on the purity of the reference materials and the inertness of the vessels and surfaces that contact the sample. High-purity specialized materials, such as those used in certified reference standards, provide the fundamental benchmark against which all measurements are calibrated. Impurities, even at the parts-per-billion level, can introduce significant systematic errors, leading to incorrect conclusions and compromising the validity of an entire study.

The choice of material for laboratory equipment also plays a critical role. For instance, in gas chromatography, the stationary phase material determines the separation efficiency of a mixture. Similarly, the composition of the mass spectrometer's ion source and detector components must be carefully controlled to minimize background noise and signal contamination. The development of advanced quartz glass for optical systems, high-density polyethylene for chemical storage, and non-reactive fluoropolymers for solvent handling are all examples of how material specialization directly enhances analytical precision.

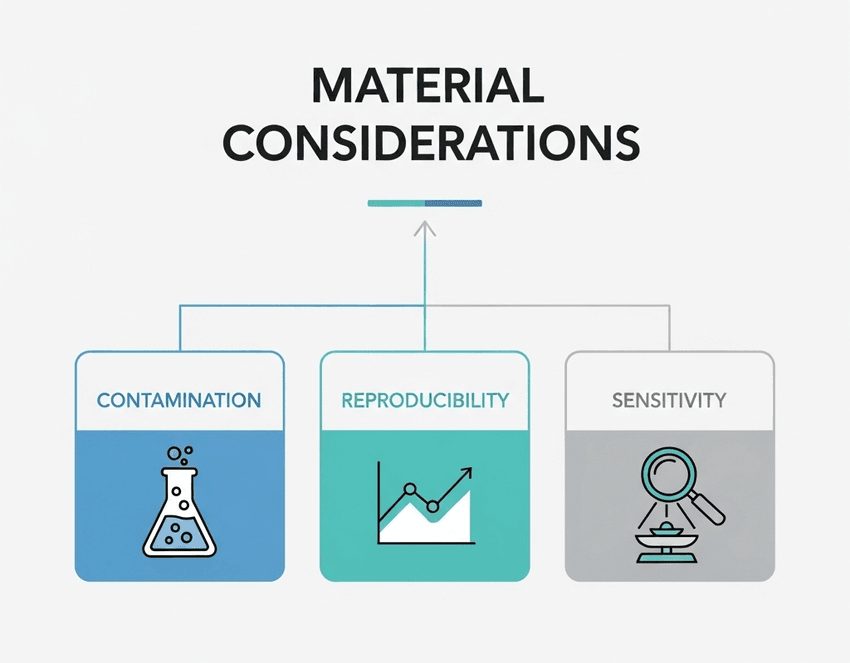

Several factors influence the choice of specialized material.

GEMINI (2025)

- Minimizing Contamination: Materials like fused silica and Teflon are chosen for their inertness and low porosity, which prevents sample adsorption or chemical reaction with the analyte.

- Ensuring Reproducibility: Standard reference materials, produced from highly purified substances, guarantee that results from different laboratories and different instruments can be compared accurately.

- Enhancing Sensitivity: In trace analysis, materials with minimal leaching properties are paramount to ensure that the detected signal is from the sample and not from the container.

These material considerations are not academic footnotes; they are foundational pillars for the accuracy and reproducibility of data in fields ranging from environmental monitoring to pharmaceutical quality control, highlighting their essential role in a wide array of industrial applications.

Revolutionizing Medicine with Advanced Biomedical Materials

The field of medicine is undergoing a revolution driven by the development of sophisticated biomedical materials. These materials are specifically engineered to interact with biological systems in a safe and effective manner, a principle known as biocompatibility. The challenges for these materials are immense, requiring them to be non-toxic, non-allergenic, and resistant to degradation within the body while often providing mechanical support or facilitating tissue regeneration.

Laboratory professionals are central to the development and validation of these materials. Their work involves a rigorous series of in-vitro and in-vivo tests to assess how a material will perform in the physiological environment. This includes everything from cytotoxicity assays to tests for inflammatory response and long-term degradation.

Key examples include:

- Implants: From hip replacements and dental implants to pacemakers, these devices rely on materials like titanium alloys and zirconia, which are chosen for their strength and inertness.

- Tissue Engineering Scaffolds: Hydrogels and advanced polymers are used to create three-dimensional frameworks that support cell growth and tissue regeneration, requiring careful control over porosity, biodegradability, and surface chemistry.

- Drug Delivery Systems: Nanoparticles and microcapsules, often made from biodegradable polymers, are designed to encapsulate therapeutic agents and release them at a controlled rate, offering targeted treatment with fewer side effects.

The comprehensive evaluation of biomedical materials ensures their safety and efficacy. This process involves complex analytical techniques, including surface characterization, mechanical testing, and advanced imaging, all of which fall within the purview of the modern laboratory. The continuous development in this sector underscores the professional significance of a deep understanding of material properties.

The Impact of Advanced Composites on Aerospace Materials

Traditional materials, like metals and ceramics, possess inherent properties that are often a trade-off between strength, weight, and flexibility. Advanced composites, on the other hand, are engineered materials comprising two or more constituent materials with significantly different physical or chemical properties, which when combined, produce a material with characteristics superior to those of the individual components. The matrix material holds the reinforcement together, while the reinforcement—typically fibers—provides the desired strength and stiffness.

The laboratory’s role in the lifecycle of advanced composites is critical, encompassing every stage from development to quality control. Material scientists and engineers in a laboratory setting can precisely control the composition and fabrication process to produce materials with exceptional strength-to-weight ratios, high resistance to fatigue, and tailored thermal expansion.

A prime example is their use in aerospace materials. The construction of modern aircraft wings, fuselages, and satellite components relies heavily on carbon fiber-reinforced polymers (CFRPs) and glass fiber-reinforced polymers (GFRPs). The reduced weight of these materials directly translates to improved fuel efficiency and payload capacity.

Laboratory professionals apply a variety of non-destructive testing (NDT) techniques to inspect composite structures for defects without compromising their integrity.

- Ultrasonic Testing: Uses high-frequency sound waves to detect internal flaws, delaminations, and voids within the composite.

- Radiography (X-ray and CT scans): Provides detailed internal images to identify cracks, porosity, and fiber misalignment.

- Thermography: Measures surface temperature variations to locate subsurface defects, as flaws can alter heat flow patterns.

This specialized testing ensures the structural integrity of these materials, a non-negotiable requirement in high-stakes fields like the aerospace industry. The meticulous characterization and testing of advanced composites are vital for unlocking their full potential.

Elevating Industrial Applications with Specialized Materials Expertise

The analysis and characterization of specialized materials are fundamental to driving innovation across numerous sectors. From the purity standards in analytical laboratories to the rigorous biocompatibility testing of medical devices and the structural integrity evaluations of aerospace materials and advanced composites, the expertise of laboratory professionals in material science is indispensable.

These materials represent more than just a collection of atoms; they embody engineered solutions to complex problems. For the modern laboratory, the ability to understand, test, and manipulate these substances is not merely a skill but a core competency that underpins scientific progress and commercial viability. The ongoing evolution of these materials will continue to present new challenges and opportunities for laboratory science, reinforcing its central role in shaping the future of industrial applications.

FAQ

What are specialized materials and how are they relevant to laboratory work?

Specialized materials are substances engineered with specific, often unique, properties for high-performance applications. Examples include advanced alloys, ceramics, and polymers. They are relevant to laboratory work as they are used to create the very tools and equipment that enable precise analysis and research. A high-purity standard, an inert reaction vessel, or a durable implant are all examples of specialized materials that directly impact a lab's ability to achieve accurate and reliable results across a broad spectrum of industrial applications.

How do aerospace materials impact laboratory testing protocols?

Aerospace materials are designed for extreme conditions, requiring stringent testing protocols to ensure reliability and safety. Laboratory testing of aerospace materials involves subjecting them to simulated environments of high temperature, pressure, and stress. Non-destructive testing methods are crucial for examining the integrity of components without causing damage. The testing of these materials often requires highly specialized equipment and analytical methodologies to assess properties like fatigue resistance, tensile strength, and corrosion behavior, validating their use in critical applications.

What are the key considerations for testing biomedical materials?

Testing biomedical materials centers on ensuring their safety and functionality within the human body. The primary consideration is biocompatibility, which involves a series of tests to confirm that the material does not provoke an adverse biological response. These tests range from in-vitro cytotoxicity assays to in-vivo studies of inflammation and tissue integration. Other considerations include mechanical properties like durability and elasticity, as well as degradation rate, if the material is designed to be absorbed by the body. All testing must adhere to strict regulatory standards to ensure patient safety and product efficacy.

How do advanced composites differ from traditional materials, and what is the role of the laboratory in their development?

Unlike traditional materials with fixed properties, advanced composites are heterogeneous, consisting of a matrix and reinforcement engineered to create a synergistic material. The tailored properties, such as a high strength-to-weight ratio and fatigue resistance, make them superior for specific, demanding roles. The laboratory's role is multifaceted, involving the initial synthesis and fabrication of the composite, followed by comprehensive characterization using a variety of analytical techniques. This includes mechanical testing, as well as non-destructive methods to detect internal defects, ensuring the material meets the rigorous performance standards required for its intended industrial applications.