Executive Summary

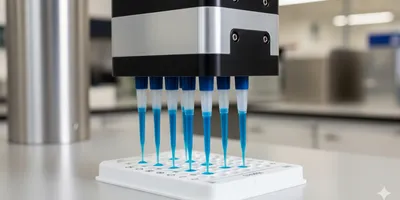

Manual pipetting is the single greatest source of error in the laboratory—and the leading cause of Repetitive Strain Injury (RSI). Moving to automation is not just about speed; it is about guaranteeing that sample #1 and sample #96 are treated exactly the same.

However, the term "Liquid Handler" covers a confusing range of hardware, from simple $5,000 electric pipetting assistants to $500,000 acoustic dispensing islands. The core decision usually boils down to Flexibility vs. Throughput. A system designed to fill 100 plates an hour (Bulk Dispenser) usually cannot pick a single "hit" from a specific well. Conversely, a flexible deck that can perform complex serial dilutions is often too slow for high-throughput screening.

For the Lab Manager, the purchase decision often hinges on the "Razor and Blade" model of consumable tips. Buying a "closed system" robot may offer better precision, but it locks you into expensive proprietary tips for the life of the instrument.

This guide outlines the physics of pipetting, the software learning curve, and the hidden operational costs to ensure you buy a robot that actually frees up your staff, rather than creating a programming burden.

1. Understanding the Technology Landscape

The market for automated liquid handling is vast and often confusing, spanning from simple, motorized pipettes to room-sized, fully integrated robotic islands. To make a sound investment, Lab Managers must first categorize the equipment based on its fundamental mechanical action: does it simply move liquid from point A to point B, or does it intelligently manipulate samples based on logic? Understanding this distinction—between a "dumb" bulk dispenser and a "smart" workstation—is the first step in avoiding a purchase that gathers dust.

Core Instrument Types