The demanding world of analytical chemistry requires more than just precise instrumentation; it requires a systematic approach to operations. For laboratory professionals, mastering analytical lab management is the key to ensuring every measurement, every result, and every report is a model of accuracy and reliability. Effective lab management is what elevates a lab's output, whether it's ensuring product quality, validating a research hypothesis, or safeguarding public health. It's the engine that drives a high-performance scientific system.

In today's fast-paced scientific landscape, the challenges are multifaceted, from complex regulatory frameworks to stringent safety standards and vast amounts of data. This article provides a comprehensive guide for modern analytical lab management, offering a blueprint for establishing a laboratory that is not just productive, but a beacon of quality, safety, and efficiency. We will explore the core pillars of effective lab management to help you transform your lab into a high-performance system capable of delivering trustworthy and repeatable results every time.

The Cornerstone of Quality: Good Laboratory and Manufacturing Practices (GLP/GMP)

At the heart of any successful analytical chemistry operation lies a non-negotiable commitment to quality. This commitment is formalized and enforced through regulatory frameworks like Good Laboratory Practice (GLP) and Good Manufacturing Practice (GMP). While these two sets of guidelines share a common goal of ensuring quality and integrity, they apply to different areas of the product lifecycle.

GLP is a quality system for non-clinical health and environmental safety studies, ensuring the integrity and authenticity of data submitted to regulatory agencies. Its principles govern the entire research process, from study design and execution to reporting. A lab adhering to GLP must have meticulously documented procedures (Standard Operating Procedures or SOPs), validated equipment, and a robust quality assurance program. The focus is on traceability: every action, every change, and every observation must be recorded in a way that is easily auditable. This ensures that the data generated is reliable and can stand up to regulatory scrutiny, which is a fundamental aspect of effective analytical lab management.

GMP, on the other hand, is concerned with the manufacturing process itself. It ensures that products are consistently produced and controlled according to quality standards. For an analytical lab that supports manufacturing, GMP dictates the procedures for testing raw materials, in-process samples, and finished products. Key principles include:

- Documentation: Everything must be documented, from batch records to equipment maintenance and calibration logs.

- Validation: All analytical methods and equipment must be validated to prove they are fit for their intended purpose.

- Traceability: All materials, from raw ingredients to final products, must be traceable back to their source.

Implementing GLP and GMP is not just about compliance; it's about building a culture of discipline and accountability. It provides a structured framework for managing risk, minimizing errors, and ultimately, producing data that can be trusted by customers, regulators, and the scientific community alike.

Mastering the Lab's Backbone: Reference Standards and Reagents Management

The accuracy of an analytical result is only as good as the quality of the reference standards and reagents used. Effective analytical lab management requires a rigorous and well-documented system for managing these critical materials. A poor quality or misidentified reference standard can invalidate an entire study, leading to significant financial loss, wasted time, and potential regulatory non-compliance.

A robust management system for reference standards should include several key components:

- Procurement and Receiving: Standards should only be sourced from reputable suppliers with documented Certificates of Analysis (CoA). Upon arrival, they must be inspected, logged into an inventory system, and verified against the CoA.

- Proper Storage: Each standard has specific storage requirements (e.g., temperature, light exposure, humidity) that must be strictly followed. This is often dictated by the manufacturer's instructions and should be monitored and documented meticulously.

- Inventory and Traceability: A digital inventory system is essential. This system should track the location, expiration date, and usage of every standard. Each use should be logged to maintain a complete chain of custody.

- Expiration and Recertification: Expiration dates must be actively managed. For in-house standards, a recertification plan should be in place, where the standard's purity and identity are periodically re-evaluated.

- Disposal: Expired or depleted standards must be disposed of in a documented and environmentally responsible manner.

To illustrate, consider a simple table outlining a best-practice approach:

Component | Best Practice in Analytical Lab Management |

|---|---|

Procurement | Source from ISO 17034 accredited suppliers. |

Storage | Use a dedicated, temperature-controlled, and monitored refrigerator/freezer. |

Inventory | Implement a LIMS (Laboratory Information Management System) to track usage and stock levels. |

Recertification | Document a clear recertification schedule based on stability data. |

Disposal | Follow all local, state, and federal hazardous waste regulations. |

By treating reference standards and reagents with the same level of care as the data itself, a lab can significantly reduce the risk of out-of-specification results and maintain the highest level of quality control, a defining characteristic of excellent analytical lab management.

Cultivating a Culture of Safety: Proactive Analytical Lab Safety Protocols

The physical well-being of lab personnel is the foundation upon which all other lab operations are built. A safe lab is an efficient lab, where incidents are prevented and the team can focus on their work with confidence. Analytical lab management must prioritize and embed safety into every aspect of daily operations. Safety is not a set of rules to be followed but a culture to be cultivated.

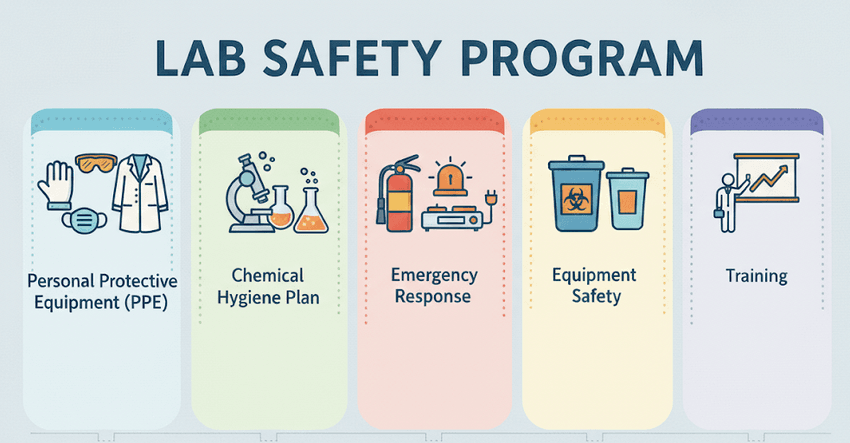

Key elements of a comprehensive lab safety program include:

Five key aspects of a rigorous lab safety program.

GEMINI (2025)

- Personal Protective Equipment (PPE): Mandate and enforce the use of appropriate PPE, including lab coats, safety goggles, gloves, and face shields. Ensure all PPE is readily available and well-maintained.

- Chemical Hygiene Plan: Develop a detailed chemical hygiene plan that outlines safe handling, storage, and disposal procedures for all chemicals in the lab. This includes a clear system for labeling, a readily accessible Safety Data Sheet (SDS) library, and guidelines for segregation of incompatible chemicals.

- Emergency Response: Every lab must have clear and practiced emergency protocols. This includes the location of first-aid kits, eyewash stations, and fire extinguishers, as well as a pre-determined evacuation plan. Regular drills are crucial to ensure the team knows how to respond effectively in a crisis.

- Equipment Safety: All analytical instruments, from high-performance liquid chromatographs (HPLC) to gas chromatographs (GC), must be regularly inspected, calibrated, and maintained according to manufacturer guidelines. Lock-out/tag-out procedures should be in place to prevent accidental startup during maintenance.

- Training: Safety training should be continuous and mandatory. This includes initial onboarding for new employees, regular refresher courses on chemical handling, and specific training for new or specialized equipment.

By actively promoting and reinforcing a safety-first mindset, lab leaders can create an environment where every team member is an active participant in maintaining a secure and productive workplace. This proactive approach to safety is a hallmark of superior analytical lab management.

Securing the Scientific Record: A Deep Dive into Analytical Data Integrity

In the digital age, the integrity of data is as important as the data itself. Regulators and clients alike demand that data be reliable, traceable, and secure. The concept of data integrity in analytical chemistry is often summarized by the acronym ALCOA+, which stands for Attributable, Legible, Contemporaneous, Original, and Accurate. The "+" adds concepts like complete, consistent, enduring, and available.

- Attributable: Every piece of data must be traceable to the person who generated it and when. This requires unique user IDs for all electronic systems.

- Legible: Data must be readable and understandable. In the digital world, this means data is stored in a format that is easily accessible and not corrupted.

- Contemporaneous: Data should be recorded at the time the work is performed. Manual transcription is a major source of error and is discouraged in modern analytical lab management.

- Original: Data must be the first, raw capture of the information, not a copy. This includes raw instrument files, not just the final report.

- Accurate: The data must be correct. This is validated through method validation, system suitability checks, and a robust quality control program.

Implementing a robust data integrity program requires a combination of technology and procedure. A modern laboratory should utilize a LIMS to manage samples, a Chromatography Data System (CDS) to control instruments and collect data, and a secure server for data storage. These systems must be validated and configured with appropriate access controls to prevent unauthorized data manipulation. By focusing on ALCOA+, lab managers can build a system that not only produces accurate results but also protects the scientific record from human error or malicious intent, a critical function of modern analytical lab management.

Elevating Expertise: Continuous Training and Professional Development for Analytical Chemists

The field of analytical chemistry is in constant evolution. New instruments, methods, and regulatory requirements emerge regularly. To keep pace, a laboratory must invest in the continuous training and professional development of its team. This is a crucial, often underestimated, component of successful analytical lab management.

A comprehensive training program should address several key areas:

- Instrument Proficiency: Training on new or updated instruments is essential. This should include not just operational knowledge but also an understanding of the instrument's principles, troubleshooting, and maintenance.

- Methodology Updates: As new analytical methods are developed or existing ones are refined, the team must be trained on the updated procedures. This ensures that the lab is always using the most efficient and accurate techniques available.

- Regulatory Training: With a dynamic regulatory landscape, from GLP to GMP, labs must ensure their staff are up-to-date on all relevant compliance requirements. This includes training on documentation, data integrity, and internal audit procedures.

- Safety Training: As mentioned, safety is an ongoing concern. Training on new chemicals, safety equipment, or emergency protocols should be a regular part of the training schedule.

- Soft Skills: Beyond technical skills, training in communication, problem-solving, and critical thinking can significantly improve team performance and lab efficiency.

Training should be a structured and documented process. Each employee should have a training matrix that outlines their required competencies and a record of all completed training modules. This provides a clear path for professional growth and ensures that the lab's collective expertise is continuously expanding. An investment in a team's skills is an investment in the future of the laboratory and is an essential pillar of effective analytical lab management.

Holistic Analytical Lab Management: A Blueprint for Excellence

Managing an analytical chemistry laboratory is a dynamic and demanding responsibility. It requires a holistic approach that seamlessly integrates a commitment to quality, a dedication to safety, and an unwavering focus on efficiency. The five pillars discussed here—GLP/GMP compliance, meticulous reference standards management, proactive safety protocols, robust data integrity, and continuous training—are not isolated tasks. They are interconnected components of a single, high-performance system.

By treating these principles as a unified whole, laboratory managers can move beyond simply reacting to problems and instead build a resilient and reliable operation. This comprehensive approach to analytical lab management ensures that every result is not just a number, but a testament to the lab's integrity and its commitment to scientific excellence. Ultimately, effective lab management transforms the laboratory from a cost center into a trusted partner, capable of delivering the precise, accurate, and trustworthy data that the modern world demands.

Frequently Asked Questions about Analytical Lab Management

What is the single most important factor for success in analytical lab management?

The most critical factor is establishing a strong culture of quality and accountability. This means every team member understands their role in maintaining data integrity, following safety protocols, and adhering to SOPs.

How can I improve data integrity in my existing laboratory?

Begin by conducting a gap analysis to identify weaknesses. Then, focus on implementing electronic systems (like a LIMS or CDS) with user access controls and audit trails. Ensure all staff receive comprehensive training on the ALCOA+ principles.

Why is it crucial to have a dedicated reference standard management system?

Reference standards are the foundation of all quantitative analysis. A robust management system ensures their identity, purity, and traceability, which is essential for generating accurate and reliable data and avoiding costly re-testing.

What are the key differences between GLP and GMP in a lab context?

GLP governs data from non-clinical studies (e.g., toxicology), ensuring its integrity for regulatory submission. GMP applies to manufacturing-related testing (e.g., QC/QA), ensuring product consistency and quality. A lab may need to adhere to both depending on its function.