For materials science laboratories, the decision to engage in industrial R&D partnerships represents a critical inflection point, fundamentally transforming the scope and speed of innovation. Successful management of these R&D partnerships dictates the translation of fundamental research into commercially viable products, demanding a professional, structured approach to collaboration that extends beyond scientific expertise to encompass stringent financial and legal governance. Effective strategy ensures that collaborative efforts not only yield scientific breakthroughs but also deliver measurable commercial and organizational value, positioning the laboratory as a vital contributor to industrial advancement.

Vetting and aligning strategic goals for R&D partnerships

Successful engagement necessitates rigorous upfront vetting to ensure mutual strategic alignment between the laboratory and its industrial collaborator.

The initial phase of any industrial R&D initiative must involve comprehensive due diligence to ensure complete goal harmonization. In materials science, this means carefully matching the laboratory’s core competencies, such as polymer synthesis or advanced characterization, with the partner’s commercial objectives, whether those are product cost reduction or the creation of novel functional coatings. A failure to align scientific milestones with commercial timelines is one of the most common causes of partnership failure. The vetting process must establish clear, quantifiable metrics for success beyond the publication of research papers, focusing instead on technology readiness levels (TRL) or demonstrable proof-of-concept indicators.

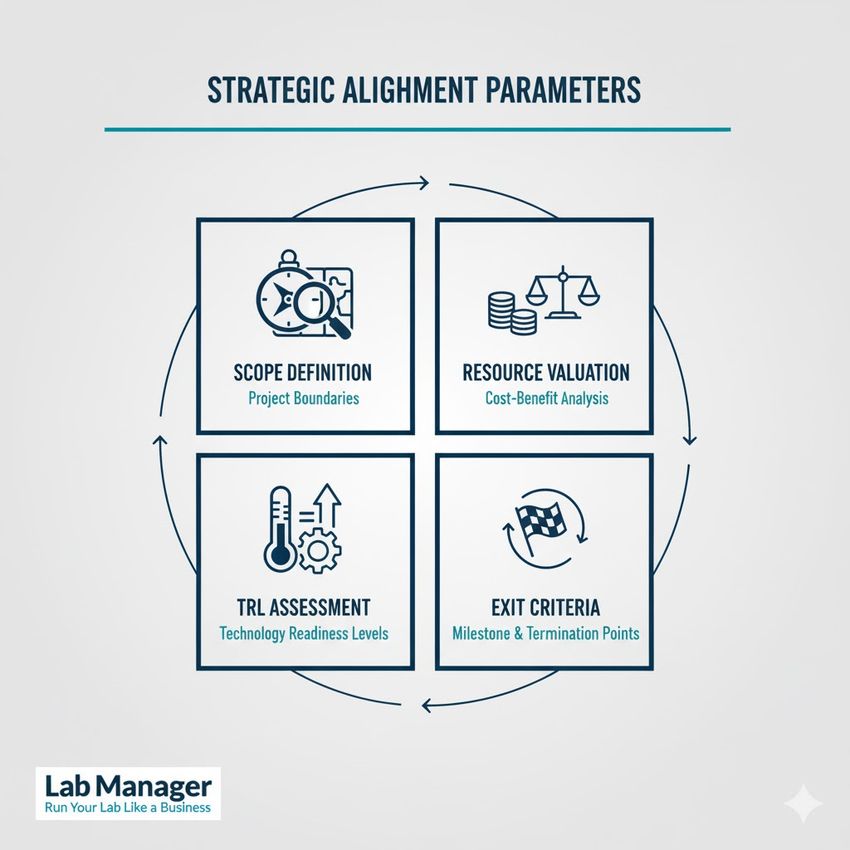

Establishing strategic alignment involves defining several key parameters:

The 4 keys to strategic lab alignment: Define, Value, Assess, Exit.

GEMINI (2025)

- Scope definition: Precisely delineate the boundaries of the collaboration. Vague agreements often lead to scope creep or mission drift, burdening laboratory resources without commensurate strategic return.

- Resource valuation: Quantify and formally document all in-kind contributions, including specialized instrumentation time, senior staff hours, and proprietary data access. This ensures fairness and transparent financial accounting from the outset.

- Technology readiness level (TRL) assessment: Agree on the target TRL for project completion. For instance, moving a material from TRL 3 (experimental proof of concept) to TRL 6 (prototype demonstration in a relevant environment) requires distinct resource allocation and risk profiles.

- Exit criteria: Pre-determine conditions under which either party may terminate the partnership, including achieving success metrics, resource depletion, or irreconcilable strategic divergence.

This foundational strategic work transforms an informal collaboration into a high-value, structured industrial R&D partnership.

Financial modeling and securing intellectual property rights

A robust financial model is crucial, moving beyond simple cost-sharing to encompass resource valuation, milestone payments, and contingency planning, coupled with defined intellectual property protocols.

Managing the financial strategies within R&D partnerships requires a sophisticated approach that addresses both immediate costs and long-term asset valuation. Laboratories must adopt standardized accounting practices to track project expenditures meticulously, ensuring compliance with both institutional and regulatory financial standards, such as those governed by the Financial Accounting Standards Board (FASB) Accounting Standards Codification (ASC) Topic 730 on Research and Development.

Financial structures commonly employed include:

Financial Model | Description | Primary Risk |

|---|---|---|

Fixed Price | Industry partner pays a set amount regardless of actual costs; scope is rigid. | Laboratory absorbs all cost overruns. |

Cost-Plus | Partner pays direct project costs plus an agreed-upon overhead percentage. | Partner may dispute overhead rates or efficiency. |

Milestone-Based | Payments are tied to the achievement of pre-defined scientific or technical outcomes. | Potential for payment delays if milestones are not clearly verifiable. |

Protecting and governing intellectual property (IP)

Defined protocols for the ownership and licensing of foreground and background intellectual property (IP) are essential to prevent future disputes and protect the laboratory's core assets. Background IP is the existing knowledge and patents held by each party prior to the agreement. Foreground IP is the new, patentable or protectable intellectual property generated directly from the partnership’s activities.

A clear IP management strategy within industrial R&D partnerships requires detailed clauses covering:

Background IP licensing: Ensuring the industry partner has a clear, non-exclusive license to use the laboratory’s existing IP necessary to utilize the resulting foreground IP.

Foreground IP ownership: Typically, options include:

- Joint Ownership: Both parties share rights, often requiring consent for commercialization.

- Laboratory Ownership with Exclusive License: The lab retains title, granting the partner a commercial license, often in exchange for royalties or specific fees.

- Partner Ownership: Less common in academic settings, this grants the partner title but usually ensures the laboratory retains research rights.

Publication rights: Establishing a review period (e.g., 30–60 days) during which the industry partner can request patent filings before public dissemination of research findings, safeguarding commercial value while upholding academic freedom.

IP maintenance and prosecution costs: Stipulating which party is responsible for the financial burden of filing, prosecuting, and maintaining resulting patents.

Implementing robust governance and communication frameworks

Effective operational governance, including formal communication structures and clear decision-making pathways, maintains project velocity and minimizes collaborative friction across all R&D partnerships.

The governance structure must be designed to manage the partnership’s life cycle, from initiation through execution and closure. This typically involves the establishment of a formal steering committee, composed of senior scientific and commercial leaders from both organizations. This committee meets regularly to review progress, allocate resources, resolve high-level conflicts, and make strategic decisions that may alter the project’s direction or budget.

Lab Management Certificate

The Lab Management certificate is more than training—it’s a professional advantage.

Gain critical skills and IACET-approved CEUs that make a measurable difference.

Key components of an effective governance framework include:

- Steering Committee Charter: A formal document outlining the committee's authority, frequency of meetings, decision-making thresholds (e.g., majority vote vs. consensus), and roles of individual members.

- Data Sharing Protocols: Implementing secure, standardized platforms for sharing raw data, experimental logs, and interim analyses. For sensitive materials science data, this must adhere to strict confidentiality agreements and relevant data protection regulations. The National Institute of Standards and Technology (NIST) Cybersecurity Framework (CSF) 2.0 (2024) provides frameworks that can guide secure data handling in these environments.

- Standardized Reporting: Requiring consistent, periodic reports that detail scientific progress, resource consumption against budget, and any identified deviations from the agreed-upon timeline or scope. Reporting must be objective, quantifiable, and accessible to both technical and commercial stakeholders.

- Conflict Resolution: A tiered process for addressing disagreements. Minor technical disputes can be resolved at the project manager level, while significant disagreements concerning IP ownership or resource allocation escalate to the steering committee, and potentially to external mediation as a final resort.

This structured communication and governance framework ensures that accountability remains high and that strategic course corrections can be executed rapidly and transparently, preserving the integrity of the R&D partnership.

Risk mitigation and maintaining laboratory compliance standards

A proactive approach to identifying and mitigating technical, financial, and regulatory risks is fundamental to successful management of industrial R&D partnerships in high-stakes laboratory environments.

The inherent complexity of industrial collaborations, particularly those involving advanced materials, introduces multiple layers of risk that must be systematically managed. Beyond the financial and IP risks previously discussed, operational and regulatory compliance represent major areas of exposure.

Compliance and safety oversight

Materials science labs engaging in industrial R&D partnerships often work with novel or hazardous substances, demanding strict adherence to occupational health and safety regulations. Compliance with directives from the Occupational Safety and Health Administration (OSHA) Laboratory Standard (29 CFR 1910.1450) in the US or similar international bodies is non-negotiable. Furthermore, any partnership dealing with internationally traded materials or technologies must also consider export control regulations, such as those administered by the U.S. Export Administration Regulations (EAR), particularly when sharing data or samples with foreign partners.

Risk mitigation strategies must encompass:

- Regulatory mapping: Prior to commencement, map all applicable regulatory requirements (e.g., environmental, health, safety, export controls) to specific project activities and assign responsibility for adherence.

- Technical feasibility reviews: Regularly schedule independent reviews to assess the technical viability of project phases. This prevents continued investment in research paths that are scientifically unsound or commercially unfeasible.

- Insurance and liability: Clearly define liability for potential experimental failures, product defects, or resulting personal injury. Insurance coverage must reflect the nature and scale of the collaborative work undertaken. The American Chemical Society (ACS) Guidelines for Chemical Laboratory Safety in Academic Institutions (2016) offers guidance on laboratory safety and liability that are relevant to R&D settings.

- Contingency resource pool: Allocate a small percentage of the total budget to an unallocated reserve, accessible only by joint committee approval, to cover unforeseen technical challenges or mandatory regulatory changes.

This rigorous risk management framework protects not only the financial investment but, critically, the personnel and reputation of the collaborating institutions.

Advancing research through structured R&D partnerships

The successful execution of industrial R&D partnerships is a measure of a laboratory’s maturity, requiring a shift from pure scientific inquiry to professionalized project management and legal diligence. By prioritizing strategic alignment, implementing robust financial and IP structures, and enforcing meticulous governance and risk mitigation protocols, laboratories can consistently translate foundational materials science into high-impact, commercial applications. This disciplined approach ensures that R&D partnerships serve as reliable, scalable models for accelerated innovation, securing a competitive advantage in a fast-moving technological landscape.

Essential questions regarding R&D partnership management

How are financial strategies tailored for materials science R&D partnerships?

Financial strategies are tailored by shifting from simple transactional funding to complex models, such as milestone-based payments, which tie funding release to the achievement of quantifiable scientific or technical objectives (e.g., synthesis of a material with a specific purity level). This structure encourages accountability and shared risk, and requires meticulous financial reporting to track resource usage against the project budget.

What is the primary risk associated with industrial R&D partnerships?

The primary risk often revolves around intellectual property (IP) disputes, particularly the disagreement over the ownership or licensing rights of foreground IP—new discoveries created during the partnership. Mitigating this risk requires a comprehensive, legally vetted collaboration agreement that explicitly defines ownership, publication rights, and commercialization pathways before any research commences.

How should IP be handled in joint R&D partnerships?

In joint R&D partnerships, IP is typically handled through pre-negotiated terms specifying ownership (sole or joint) and licensing (exclusive or non-exclusive). The laboratory often retains ownership of the core technology while granting the industry partner an exclusive, royalty-bearing license for specific commercial fields, ensuring the lab’s continued ability to conduct research and potentially partner with other entities in unrelated fields.

Why is third-party referencing important in R&D agreements?

Including references to authoritative third-party standards and regulations, such as the FDA's Current Good Manufacturing Practice (CGMP) regulations or similar global guidelines, strengthens the trustworthiness (EEAT) and enforceability of the agreement. This ensures that the research process and resulting materials meet recognized safety, quality, and ethical criteria, protecting both partners from compliance liabilities.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.