Contamination control

Credit: NuAire

An air pump continuously circulates chamber air through a HEPA filter in a closed-loop system, maintaining consistent, clean air conditions. The incubator chamber is made from smooth stainless steel with coved corners and external filters, simplifying surface decontamination. Additionally, most models offer a 145°C high heat decontamination cycle that runs in just eight hours, during which the filters and most sensors can remain installed.

Touch panel display

Credit: NuAire

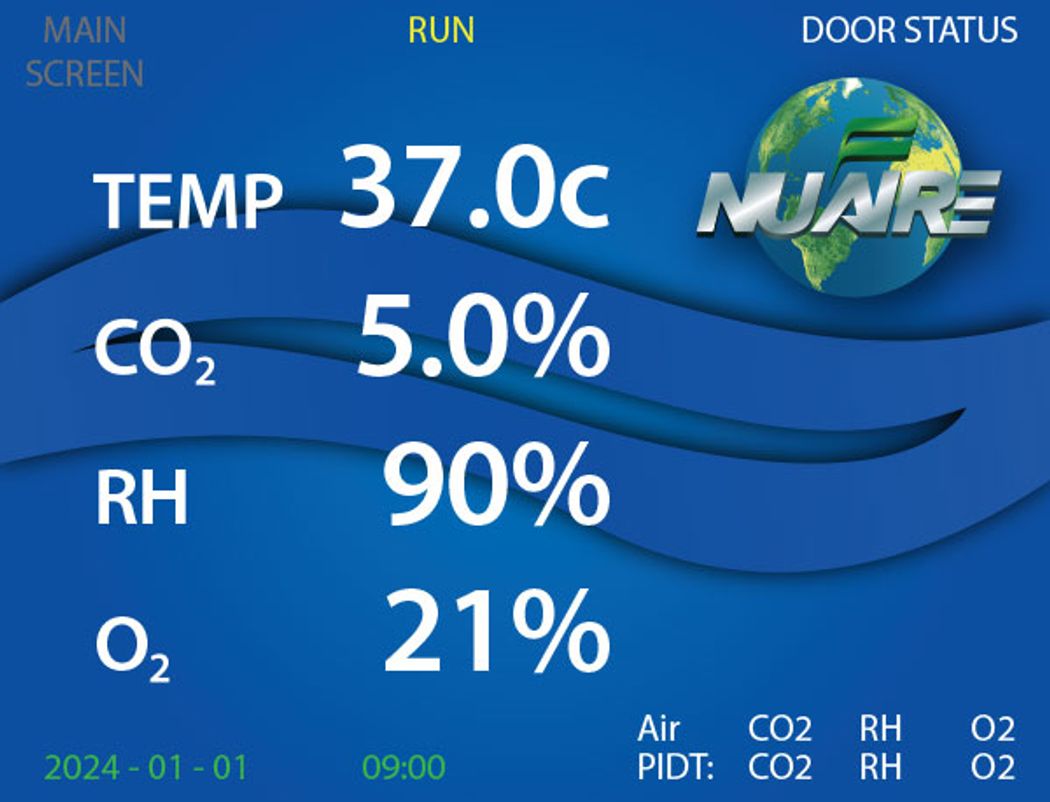

The user-friendly interface simplifies daily operations, enabling effortless adjustment of set points, easy access to chamber history, quick initiation of calibration procedures or decontamination cycles as applicable, and customizable reminders. It also displays the measured values of all controlled parameters—such as temperature, oxygen, carbon dioxide, and relative humidity—which vary based on the model.

Behind the curtain: How an In-VitroCell works

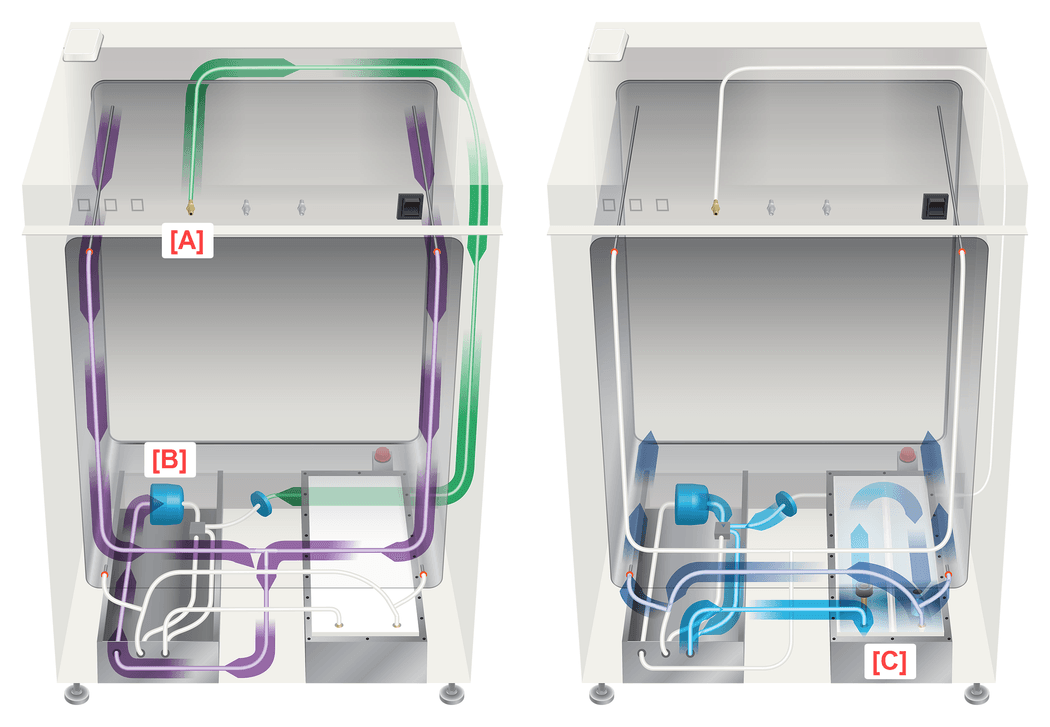

Note: Illustrations show the view from the back of the incubator.

Credit: NuAire

The incubator routes fresh air and gas through disk filters located on the front [A] and continuously recirculates existing chamber air through a separate bay under the chamber [B]. This bay also contains a HEPA filter, an infrared CO2 sensor, and a Zirconia O2 sensor. If additional humidity is needed, as determined by the relative humidity sensor, the air is passed through a humidity reservoir [C] before being reintroduced into the chamber. Additionally, heaters around the chamber, in the door, and around its opening, provide uniform heat distribution, regardless of external temperature fluctuations.

Note: Control varies by model. All parameters listed are controlled by the NU-5741 and NU-5841 models.

To learn more, visit www.nuaire.com