The integrity of data generated by environmental labs begins with meticulously controlled environmental sampling procedures. Effective lab safety protocols are critical, starting with the identification and mitigation of all potential field hazards. These procedures rely heavily on the correct application and maintenance of personal protective equipment (PPE), which serves as the final and most immediate barrier between the professional and potential contaminants or physical dangers encountered during sample collection. Adherence to strict guidelines regarding PPE usage protects personnel and simultaneously safeguards the collected samples from cross-contamination, a dual imperative in maintaining data quality.

Fundamental principles of hazard identification and risk assessment for environmental sampling

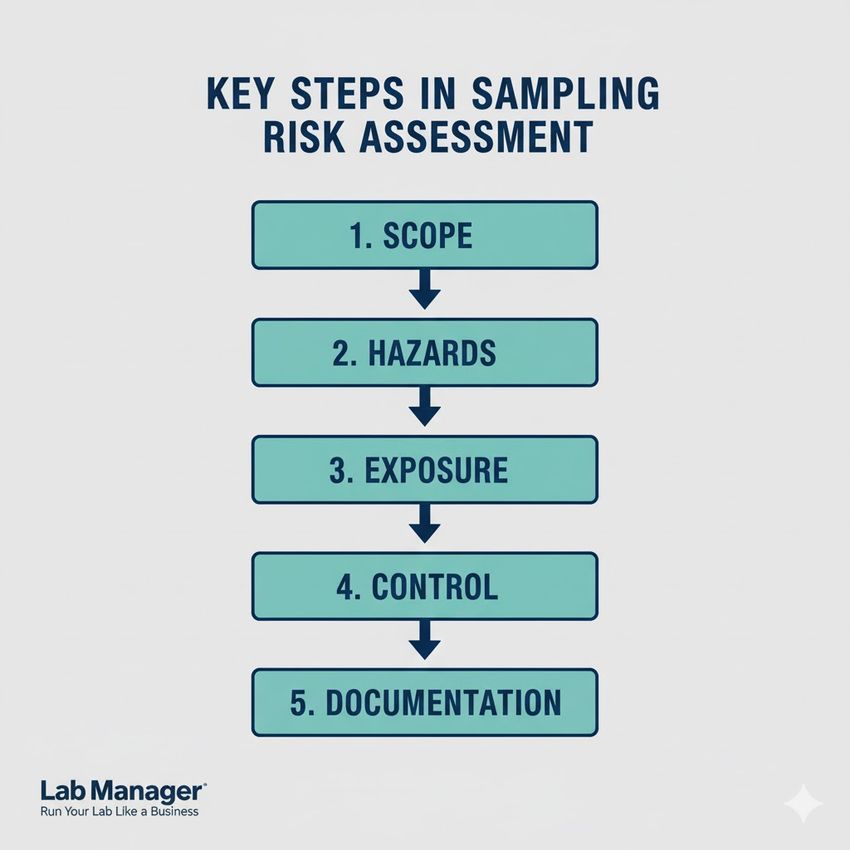

Comprehensive hazard identification and risk assessment form the bedrock for effective PPE selection in environmental sampling. Before any fieldwork commences, a thorough analysis of the site and the expected sample matrix is essential to define the required level of protection and the necessary lab safety controls. This process moves through a strict hierarchy, prioritizing elimination and engineering controls before relying on PPE.

A detailed risk assessment systematically evaluates potential hazards, including physical, chemical, and biological threats. Physical hazards are those inherent to the location, such as uneven terrain, weather, or proximity to industrial operations. Chemical hazards involve potential exposure to known or suspected contaminants in the air, water, or soil matrix. Biological hazards include pathogenic microorganisms, venomous organisms, or allergens present at the site.

The assessment requires professionals to consider the probability and severity of exposure for each identified hazard. This analysis dictates the appropriate level of PPE, ensuring that the protection provided is neither insufficient, leading to exposure, nor overly burdensome, which can introduce new ergonomic risks or heat stress. Regulatory bodies, such as the U.S. Occupational Safety and Health Administration (OSHA), provide foundational frameworks for workplace hazard analysis, notably 29 CFR 1910.132 (General Requirements), that are directly applicable to field activities.

Key steps in environmental sampling risk assessment:

These are the five main steps in environmental sampling risk assessment.

GEMINI (2025)

- Scope Definition: Clearly define the sampling area, the media (soil, water, air), and the known/suspected contaminants.

- Hazard Categorization: Classify potential hazards as chemical, biological, or physical.

- Exposure Pathway Analysis: Determine how professionals might encounter the hazards (inhalation, dermal contact, ingestion, injection).

- Control Implementation: Apply the hierarchy of controls (elimination, substitution, engineering, administrative), with PPE being the last line of defense.

- Documentation and Review: Record the findings, document the chosen PPE, and review the assessment regularly.

Selecting appropriate personal protective equipment for chemical and biological exposure

Selecting the right PPE requires an understanding of the specific exposure risks associated with the environmental sampling matrix. Incorrect selection can lead to permeation, degradation, or breakthrough, compromising the health of the professional and the integrity of the sample.

Dermal protection: Gloves, suits, and chemical resistance

Dermal exposure is one of the most common pathways for chemical and biological uptake in fieldwork. Gloves must be selected based on the chemical resistance to the specific substances encountered. Permeation data, which measures the rate at which a chemical passes through the glove material, is paramount. This data is frequently derived from testing protocols such as ASTM F739, which defines the standard method for evaluating the permeation resistance of protective clothing materials against hazardous liquids. Different glove materials, such as nitrile, neoprene, butyl rubber, and Viton, offer varying protection levels against different classes of contaminants. For instance, nitrile gloves are often suitable for general environmental fieldwork but may fail rapidly when exposed to high concentrations of certain organic solvents.

For gross contamination or working in highly contaminated zones, full-body protection, such as splash suits or fully encapsulated suits, may be necessary. These suits must meet performance criteria, often aligned with international standards like ISO 16602 (which classifies protective clothing based on hazard levels) and sizing specifications like ANSI/ISEA 101 (Sizing for Single-Use, Limited-Use, and Multi-Use Protective Clothing) to ensure proper fit and coverage. Maintaining the physical integrity of this PPE is crucial; tears or punctures negate their protective function.

Contaminant Class | Preferred Glove Material | Key Consideration |

|---|---|---|

Petroleum Hydrocarbons | Nitrile, Viton | Permeation rate (breakthrough time) |

Strong Acids/Bases | Neoprene, Butyl Rubber | Degradation and physical resistance |

Biological Agents/Microorganisms | Nitrile, Latex (non-allergenic) | Barrier integrity and tear strength |

Sharp Objects/Abrasion | Leather (under-glove), Kevlar blend | Puncture and cut resistance |

Respiratory protection for airborne hazards

Where environmental sampling activities may disturb contaminated matrices and create aerosols, dust, or volatile organic compound (VOC) plumes, respiratory protection is mandatory. The selection of respirators depends on the contaminant's physical state (particulate or gas/vapor), its concentration, and the established occupational exposure limits.

For particulates (e.g., asbestos, heavy metal dusts, bioaerosols), filtering facepiece respirators (FFRs), such as N95, N99, or P100, are used. For gaseous or vapor hazards, air-purifying respirators (APRs) with appropriate chemical cartridges are required. Cartridges are specifically rated to filter certain compounds (e.g., organic vapors, acid gases). Fit testing, a critical element of any respiratory protection program, must be conducted regularly to ensure a tight seal between the respirator and the professional’s face. The World Health Organization (WHO) provides global guidance on the use and standards of respiratory PPE in high-risk environments.

Mitigating physical and environmental hazards in field operations

Beyond chemical and biological threats, physical and environmental hazards often pose the most immediate risks during environmental sampling. Effective lab safety extends into the field by addressing these risks proactively.

Physical hazards commonly encountered include slick surfaces, uneven terrain, excavations, and falling objects. Appropriate hard hats and high-visibility vests are essential when working near vehicle traffic or active construction/industrial zones. Steel-toed or composite-toed boots with slip-resistant soles are non-negotiable for protecting against compression injuries and improving traction on slippery surfaces.

The thermal environment presents significant challenges. Exposure to extreme heat can lead to heat exhaustion or stroke, especially when wearing impermeable protective suits. Conversely, extreme cold requires insulated, layered PPE to prevent hypothermia and frostbite. Sampling plans must account for climate-related hazards and incorporate administrative controls such as mandatory hydration breaks, buddy systems, and monitoring for signs of heat or cold stress. The choice of PPE must balance necessary chemical protection with the need for heat dissipation.

Environmental and physical hazard controls:

- Visibility: Use high-visibility vests or jackets (ANSI Class 2 or 3) near traffic or heavy machinery.

- Foot Protection: Non-slip, puncture-resistant boots with ankle support for uneven terrain.

- Eye and Face Protection: Safety glasses or goggles, particularly when operating power tools or near splashing liquids. Safety glasses should comply with ANSI Z87.1 standards.

- Noise Exposure: Use earplugs or earmuffs if working near loud equipment to prevent long-term hearing hazards.

- Insect/Animal Exposure: Employ specialized clothing treatments and awareness training to mitigate risks from venomous organisms or disease-carrying insects prevalent at the environmental sampling site.

Implementing PPE decontamination, disposal, and quality assurance for environmental labs

The final phase of the PPE lifecycle—decontamination, proper disposal, and quality assurance—is essential for protecting laboratory professionals and preventing sample contamination. In environmental labs, the potential for carrying contaminants from the field back into the laboratory or community is a significant hazard.

Decontamination protocols and sample integrity

Decontamination, or "doffing," procedures must be meticulous. Contaminated PPE must be removed in a designated exclusion zone using a process that prevents the outside (contaminated) surface from touching the wearer's skin or inner garments. For high-hazard sites, multi-stage decontamination lines, including wash, rinse, and inner-layer removal stations, are necessary. All decontamination solutions and wastes must be collected and managed according to regulatory requirements, often classified as hazardous waste.

Failure to follow stringent decontamination procedures not only poses a direct health hazard but also introduces the risk of cross-contamination. Cross-contamination can lead to false positives in subsequent lab analyses, severely compromising the credibility of environmental sampling data.

Disposal and quality assurance

Disposable PPE (gloves, coveralls, respirator cartridges) must be segregated and disposed of correctly. Items contaminated with hazardous substances must be placed into appropriate containers, labeled, and tracked as hazardous waste. Non-contaminated items can often be disposed of as general solid waste, though this requires careful verification of the absence of hazards.

Quality assurance in the PPE program relies on training and inventory management. Professionals must receive initial and recurring training on proper use, fit-checking, doffing, and the limitations of their PPE. Environmental labs must also ensure a robust inventory system is in place to track expiration dates for critical items like respirator cartridges and ensure a continuous supply of tested, quality equipment. The American Society for Testing and Materials (ASTM) provides standards for material performance and testing that environmental labs should reference when procuring PPE.

Reinforcing lab safety: Essential measures for mitigating environmental sampling hazards

Effective management of PPE and field hazards is non-negotiable for environmental sampling success. By embedding comprehensive risk assessment and strict protocols for PPE selection, use, decontamination, and disposal into daily operations, environmental labs protect personnel health, ensure lab safety, and guarantee the defensibility of their analytical results. The commitment to maintaining the final barrier of protection, coupled with thorough training, elevates the overall quality and trustworthiness of environmental data collection processes.

Frequently Asked Questions about PPE and Environmental Sampling Hazards

What is the primary function of PPE in environmental sampling fieldwork?

The primary function of PPE is to act as the last line of defense, serving as a barrier to prevent dermal, respiratory, and ocular exposure to chemical, biological, and physical hazards encountered during environmental sampling activities.

How does proper PPE disposal prevent cross-contamination in environmental labs?

Proper PPE disposal, including the segregation of contaminated items, prevents the transfer of field contaminants back to clean areas in the environmental labs, thus mitigating the risk of cross-contamination and protecting the integrity of all collected samples.

Which regulatory body provides the framework for classifying chemical PPE resistance?

Regulatory bodies and industry organizations, such as the American National Standards Institute (ANSI) and ASTM International, provide the testing standards and frameworks used to classify chemical resistance and performance of various types of PPE, including gloves and protective suits.

Why is fit testing essential for respiratory protection during environmental sampling?

Fit testing is essential because an inadequate seal between the face and the respirator allows ambient air, potentially containing airborne hazards, to bypass the filter material, compromising the protective function of the PPE and exposing the wearer.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.