Agricultural laboratories play a critical role in the global food supply chain by detecting harmful substances. This function makes pesticide residue analysis a cornerstone of modern food safety programs. Identifying these minute chemical traces ensures consumer health and regulatory compliance. However, the analytical process exposes laboratory personnel to significant operational risks that require stringent chemical safety protocols. Advanced detection technologies continue to evolve, yet the fundamental need for rigorous safety standards remains constant. Laboratories must prioritize these standards to protect analysts handling hazardous matrices and concentrated standards.

Modern techniques for pesticide residue detection

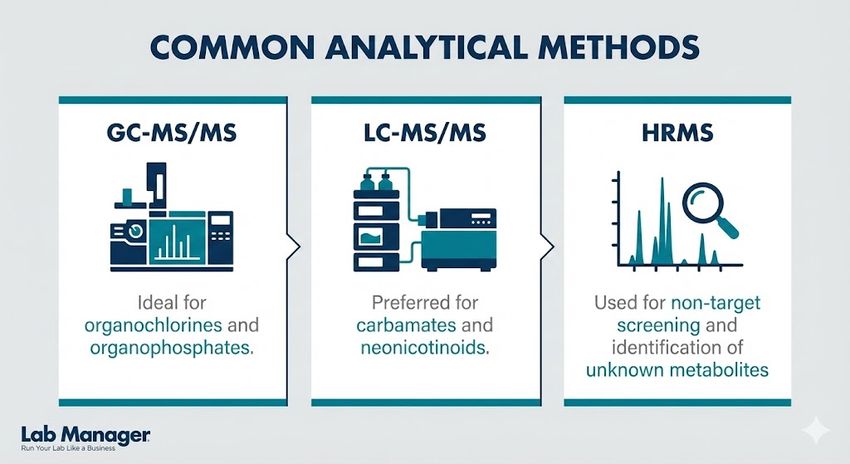

Advanced chromatographic methods allow analysts to detect minute chemical traces within complex food matrices with high precision. Laboratory professionals rely on high-sensitivity instrumentation to identify pesticide residue levels that often fall in the parts-per-billion (ppb) range. Gas Chromatography-Mass Spectrometry (GC-MS) and Liquid Chromatography-Mass Spectrometry (LC-MS) serve as the industry standards for these analyses. GC-MS effectively analyzes volatile and semi-volatile compounds, while LC-MS targets non-volatile, thermally unstable, or polar pesticides. These techniques require rigorous sample preparation to isolate targets from interfering substances such as lipids, sugars, and pigments found in agricultural commodities.

The adoption of the QuEChERS (Quick, Easy, Cheap, Effective, Rugged, and Safe) method has revolutionized sample preparation. This dispersive solid-phase extraction approach reduces the time analysts spend handling hazardous solvents compared to traditional liquid-liquid extraction. However, even with streamlined methods, the presence of concentrated analytical standards necessitates unwavering attention to chemical safety. Laboratories must maintain validated methods that comply with guidelines from organizations like the AOAC International to ensure reproducibility and accuracy.

Common analytical methods:

Precision in the laboratory starts with matching the correct analytical method to your target compounds.

GEMINI (2025)

- GC-MS/MS: Ideal for organochlorines and organophosphates.

- LC-MS/MS: Preferred for carbamates and neonicotinoids.

- High-resolution mass spectrometry (HRMS): Used for non-target screening and identification of unknown metabolites.

Chemical safety hazards in sample preparation

The extraction and concentration phases of analysis present the highest risk of personnel exposure to hazardous solvents and concentrated analytes. Sample preparation in pesticide residue testing involves the use of organic solvents such as acetonitrile, ethyl acetate, and hexane. These chemicals pose distinct health hazards, ranging from acute toxicity to long-term issues like carcinogenicity or reproductive toxicity. Agricultural laboratories must implement comprehensive hygiene plans to mitigate inhalation and dermal exposure risks. The Occupational Safety and Health Administration (OSHA) provides specific permissible exposure limits (PELs) for these solvents, which facility managers must monitor strictly.

Handling analytical standards requires an even higher tier of caution. These standards consist of pure pesticide active ingredients, often at high concentrations (greater than 98% purity). Accidental exposure to stock solutions during dilution protocols can result in immediate adverse health effects. Analysts must handle these materials within certified fume hoods and utilize appropriate containment devices.

Key safety considerations during preparation:

Hazard category | Source material | Prevention strategy |

|---|---|---|

Inhalation | Volatile solvents (Hexane, Acetone) | Use certified chemical fume hoods with adequate face velocity. |

Dermal absorption | Pesticide stock solutions | Wear glove materials with breakthrough times appropriate for the specific solvent. |

Physical injury | Centrifuges, homogenizers | Ensure equipment guards are in place and balance loads precisely. |

Fire/explosion | Flammable extraction solvents | Store solvents in flame-resistant cabinets and ground all transfer equipment. |

Operational safety in agricultural laboratories

Agricultural laboratories handling crop samples face unique challenges due to the diverse matrices involved, ranging from high-water content fruits to high-fat oilseeds. Ensuring chemical safety in these environments requires protocols specifically designed for pesticide residue workflows. Agrilabs must account for the unknown nature of incoming samples. These samples may contain illegal or high-concentration pesticide mixtures. This reality necessitates a higher level of universal precaution than standard chemical manufacturing labs. Clinical labs deal with biological pathogens, but agrilabs handle anthropogenic chemicals designed specifically to be toxic to biological systems. Consequently, the "unknown" sample represents a distinct chemical threat. High-throughput environments common in the agricultural sector often process hundreds of samples daily. This volume increases the statistical probability of spills or exposure events. Therefore, laboratory managers must enforce rigorous standard operating procedures (SOPs) governing the receiving, homogenizing, and disposal of agricultural samples to maintain a safe workspace.

Regulatory compliance and maximum residue limits

Adherence to federal and international standards ensures data integrity, legal compliance, and worker protection. Regulatory bodies establish Maximum Residue Limits (MRLs) to define the highest level of a pesticide residue that is legally tolerated in or on food or feed. In the United States, the Environmental Protection Agency (EPA) sets these tolerances, while the Food and Drug Administration (FDA) and the United States Department of Agriculture (USDA) enforce them through monitoring programs. For laboratories, compliance involves not only meeting analytical performance criteria but also adhering to safety regulations that govern hazardous waste disposal and worker right-to-know laws.

International trade relies on the harmonization of these standards. The Codex Alimentarius Commission often guides this harmonization to facilitate global commerce. Laboratories conducting pesticide residue analysis for export certification must navigate varying global MRLs. This regulatory complexity impacts chemical safety protocols as well; testing for a broader range of international analytes often requires stocking a larger inventory of hazardous reference standards. Maintaining ISO/IEC 17025 accreditation demonstrates a laboratory's technical competence and commitment to a robust quality management system, which inherently includes safety management.

- EPA: Sets tolerances for pesticide residues on food commodities.

- FDA: Enforces tolerances for domestic and imported foods (excluding meat/poultry).

- OSHA: Regulates laboratory safety standards (29 CFR 1910.1450).

Engineering controls and personal protective equipment

Physical barriers and specialized gear provide the final line of defense against hazardous exposure in the laboratory environment. Engineering controls serve as the primary means of preventing exposure to airborne contaminants during pesticide residue analysis. Chemical fume hoods must function at optimal face velocities to capture solvent vapors and particulate matter generated during sample grinding or homogenization. Laboratory managers should schedule annual certification of these hoods and ensure analysts understand proper sash positioning. Beyond ventilation, the design of the laboratory itself—including designated weighing rooms for high-toxicity standards—contributes to overall safety.

Personal Protective Equipment (PPE) acts as the last barrier between the hazard and the professional. Standard nitrile gloves may not provide adequate protection against all solvents used in residue analysis; for instance, acetonitrile can permeate disposable nitrile quickly. Analysts must consult chemical compatibility charts to select appropriate hand protection. Eye protection, specifically chemical splash goggles, remains mandatory when handling liquid solvents. In scenarios involving highly toxic reference materials, analysts may require respiratory protection if engineering controls fail to reduce exposure below safe limits.

Essential PPE for residue analysis:

- Chemical splash goggles: Protects against solvent splashes during extraction.

- Lab coats: Flame-resistant coats preferred when working with flammable solvents.

- Specialized gloves: Laminate or heavy-gauge nitrile for handling concentrated stocks.

- Closed-toe footwear: Prevents injury from spills or falling glassware.

Ensuring sustainable pesticide residue testing and safety

The demand for comprehensive pesticide residue testing continues to grow as global food safety regulations tighten. Laboratories must balance the need for lower detection limits and higher throughput with the absolute necessity of chemical safety. By investing in modern instrumentation, adhering to regulatory frameworks, and fostering a culture of safety awareness, agricultural laboratories protect their most valuable asset—their personnel—while ensuring the safety of the global food supply.

FAQ

What is the difference between single-residue and multi-residue methods?

Single-residue methods target a specific pesticide or a small group of chemically related compounds, often used for analytes difficult to detect via standard screening. Multi-residue methods analyze hundreds of pesticides simultaneously in a single run, offering greater efficiency for general screening purposes.

How often should a laboratory validate its pesticide residue methods?

Laboratories must validate methods during initial development and re-validate whenever significant changes occur, such as new instrumentation, modified extraction procedures, or new sample matrices. Ongoing verification using quality control samples should occur with every analytical batch.

Why is chemical safety training critical for pesticide analysts?

Pesticide analysts handle concentrated toxic compounds and large volumes of organic solvents daily. comprehensive safety training ensures personnel recognize specific hazards, understand proper handling techniques, and know how to respond effectively to spills or exposure incidents.

What are the primary challenges in testing high-fat matrices?

High-fat matrices, such as oils or nuts, introduce co-extractives that can interfere with instrumental analysis and damage chromatography columns. These samples often require additional clean-up steps, such as freezing-out lipids or using specialized adsorbents, which increases the handling time and potential chemical exposure.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.