X-ray diffraction (XRD) and X-ray fluorescence (XRF) analysis serve as cornerstones in material science. However, these powerful tools require strict adherence to safety standards to prevent accidental exposure. Laboratory managers and safety officers must prioritize radiation protection to mitigate ionization risks and maintain regulatory compliance within XRD/XRF labs. The high-intensity primary beams generated by analytical X-ray equipment pose significant hazards. They can cause severe radiation burns and long-term biological damage in fractions of a second. Establishing a culture of safety involves understanding the unique properties of analytical X-ray sources. These sources differ significantly from medical X-ray systems in terms of intensity and wavelength. A comprehensive safety program combines engineering controls, administrative procedures, and personal monitoring to create a secure environment for researchers and technicians.

Regulatory standards for radiation protection

Federal and state regulations establish the non-negotiable baseline for safety operations within analytical X-ray facilities.

The foundation of radiation protection in the United States rests on standards set by the Occupational Safety and Health Administration (OSHA) and the Nuclear Regulatory Commission (NRC). These sit alongside performance standards from the Food and Drug Administration (FDA). Specifically, Title 21 CFR 1020.40 governs the performance standards for ionizing radiation-emitting products. It mandates specific safety features for cabinet X-ray systems. Additionally, the ANSI/HPS N43.2 standard ("Radiation Safety for X-ray Diffraction and Fluorescence Analysis Equipment") serves as the primary industry consensus standard. It offers detailed operational guidelines beyond basic legal requirements. Compliance requires a thorough understanding of these statutes. They dictate exposure limits, signage requirements, and equipment specifications. State-level radiation control programs often impose additional registration and inspection requirements. XRD/XRF labs must meet these to operate legally.

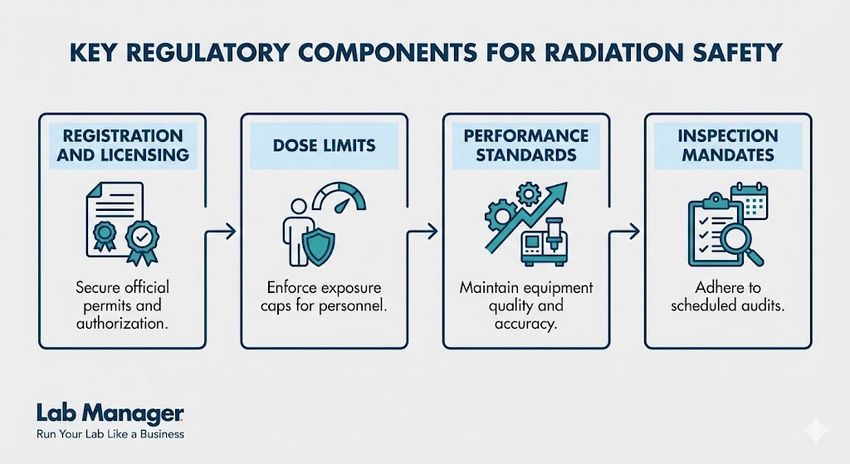

From securing initial licensing to maintaining audit-ready inspection standards, these four pillars ensure your laboratory remains compliant and your personnel remain safe.

GEMINI (@026)

Key regulatory components include:

- Registration and licensing: Most jurisdictions require the registration of all radiation-producing devices prior to operation.

- Dose limits: Regulations establish maximum permissible dose limits for occupational workers. These are typically set at 5 rem (0.05 Sv) per year for whole-body exposure, though facilities should aim significantly lower.

- Performance standards: Equipment must meet manufacturing standards regarding leakage radiation. Generally, this must not exceed 0.5 mR/hr at 5 centimeters from the cabinet surface.

- Inspection mandates: Periodic inspections by regulatory bodies ensure that equipment functions correctly. They also verify that administrative logs remain up to date.

Adhering to these regulations protects the facility from legal liability. More importantly, it protects staff from harm. The International Commission on Radiological Protection (ICRP) provides further guidance. They emphasize the optimization of protection where exposures must remain as low as reasonably achievable (ALARA). Implementing these standards requires active participation from the Radiation Safety Officer (RSO). The RSO holds the authority to halt operations if compliance lapses occur.

Engineering controls in XRD/XRF labs

Physical barriers and automated fail-safe mechanisms provide the first and most reliable line of defense against radiation exposure in analytical laboratories.

Modern analytical X-ray units rely heavily on engineering controls to isolate the user from the primary beam. In XRD/XRF labs, the equipment typically falls into two categories: enclosed (cabinet) systems and open-beam systems. Cabinet systems fully enclose the X-ray tube and the sample. They offer the highest level of inherent safety. These units utilize high-density shielding, usually lead or lead-equivalent composites, to attenuate radiation to safe levels. The design ensures that the unit cannot generate X-rays unless the enclosure remains fully secured. Open-beam systems present higher risks. Consequently, external shielding and room design become critical factors in the radiation protection strategy.

Essential engineering safety features include:

- Fail-safe interlocks: These electrical or mechanical devices immediately cut power to the X-ray generator or close the shutter. This occurs if a user opens a protective cabinet door or removes a shielding panel.

- Captive key systems: This control mechanism ensures that the X-ray generation cannot occur without a specific key. The operator must insert and turn this key, preventing unauthorized activation.

- Beam stops and collimators: Primary beam stops must effectively absorb the unattenuated beam after it passes through or reflects off the sample. This prevents the beam from escaping the immediate experimental area.

- Warning lights: "X-RAY ON" indicators, typically fail-safe bulbs, must illuminate near the tube head and the control panel whenever the generator energizes.

The integrity of shielding materials degrades over time or through physical damage. This necessitates regular physical inspections. Shielding effectiveness depends on the energy of the X-ray beam. Therefore, any modification to the X-ray source requires a re-evaluation of the shielding thickness. Operators should never rely solely on interlocks for protection. However, these mechanisms serve as the critical hardware barrier preventing accidental entry into high-radiation zones. In some instances, users must bypass interlocks for maintenance or alignment. This procedure is strictly limited to qualified personnel. Temporary shielding and remote viewing devices typically replace the standard engineering controls to maintain safety during these times.

Administrative protocols for radiation protection

Operational procedures and comprehensive training programs supplement engineering controls to address the human element of laboratory safety.

While engineering controls provide physical barriers, administrative controls dictate the behavior and processes that prevent accidents. Every facility operating analytical X-ray equipment must maintain a rigorous written radiation safety program. This program outlines the specific responsibilities of the RSO, the authorized operators, and the support staff. Standard Operating Procedures (SOPs) constitute the core of administrative control. They detail step-by-step instructions for startup, sample loading, data acquisition, and shutdown. These documents must explicitly state prohibited actions, such as placing hands in the beam path or modifying safety devices.

Critical administrative components include:

- Authorized user training: Personnel must complete specific training on radiation physics, biological effects, and the specific operation of the lab's equipment before using any X-ray device.

- Access control: Laboratories must restrict access to X-ray areas to authorized personnel only. This often involves utilizing keycard access or digital logs to track entry.

- Signage and posting: Explicit warning signs, such as "Caution: High Intensity X-Ray Beam," must appear on equipment housings and laboratory entrances. These alert staff and visitors of potential hazards.

- Pregnancy declarations: Protocols must exist for voluntary pregnancy declarations. These trigger lower dose limits and enhanced monitoring for the fetal gestation period.

Alignment and maintenance safety protocols: Beam alignment procedures represent the most hazardous activity in XRD/XRF labs. They require a dedicated, heightened set of administrative controls. Statistics indicate that the majority of radiation accidents in analytical laboratories occur during the alignment of the primary beam. This often happens when safety enclosures require temporary removal or bypass. During these critical operations, the SOP must mandate the use of reduced beam current and voltage. This lowers the intensity of the radiation. Furthermore, operators must utilize long-handled tools and fluorescent alignment screens to manipulate components. This ensures hands never enter the primary beam path. Administrative rules should strictly forbid performing alignments alone. A second observer serves as a safety backup to ensure protocol adherence and provide immediate assistance if an incident occurs.

Personal dosimetry monitoring in XRD/XRF labs

Continuous monitoring verifies the effectiveness of safety protocols and documents occupational exposure levels for legal and medical records.

Personal dosimetry serves as the final check in the safety system. It quantifies the actual radiation dose received by laboratory personnel. In XRD/XRF labs, the primary risk involves extremities, specifically fingers and hands. These areas may inadvertently approach the collimated beam during sample adjustment. Consequently, ring dosimeters (extremity badges) often prove more critical than whole-body badges in these specific environments. The data collected from these devices provides a longitudinal record of exposure. This allows safety officers to detect upward trends that might indicate procedural failures or equipment degradation.

Dosimetry and monitoring best practices involve:

- Appropriate badge placement: Personnel must wear whole-body badges on the torso and ring badges on the hand closest to the radiation source. The detector element must face the source.

- Device technology: Laboratories typically use Thermoluminescent Dosimeters (TLD) or Optically Stimulated Luminescence (OSL) badges due to their high sensitivity and stability.

- Survey meter availability: A calibrated Geiger-Müller counter or ionization chamber with a thin window must remain accessible. This is necessary to detect low-energy X-ray leakage and scatter.

- Regular review: The RSO must review dosimetry reports monthly or quarterly to ensure no individual approaches regulatory limits.

Radiation protection strategies rely on the ALARA principle. Even if doses remain below legal limits, the laboratory must strive to reduce them further through time, distance, and shielding. Time involves minimizing the duration of exposure-prone activities. Distance leverages the inverse square law, where doubling the distance from the source reduces exposure by a factor of four. Shielding involves using appropriate materials to block radiation. A sudden spike in a dosimetry report triggers an immediate investigation to determine the cause. This applies whether it stems from equipment failure, operator error, or a lapse in safety discipline.

Routine maintenance for radiation protection systems

Regular equipment assessment prevents safety system degradation and ensures the ongoing integrity of the radiation protection infrastructure.

Maintenance in XRD/XRF labs extends beyond ensuring data quality; it is a critical safety function. Over time, shutter mechanisms can stick, interlock switches can fail, and shielding integrity can suffer from mechanical wear. A proactive maintenance schedule detects these issues before they result in personnel exposure. The RSO or a qualified service technician performs these inspections. They document every test and repair in the equipment logbook. This documentation proves vital during regulatory inspections. It demonstrates the facility's commitment to continuous safety monitoring.

Standard maintenance and survey tasks include:

- Leakage radiation surveys: Operators must perform surveys using a calibrated meter annually, or after any tube replacement or realignment. This ensures leakage remains within the 0.5 mR/hr limit for cabinet systems.

- Interlock testing: Technicians must functionally test safety interlocks at regular intervals (typically every three to six months). This verifies they successfully terminate X-ray generation when tripped.

- Warning light verification: Staff must check all "X-RAY ON" and "SHUTTER OPEN" indicators daily to ensure bulbs function correctly.

- Cooling system checks: verifying the integrity of cooling systems prevents tube overheating. Overheating can damage the anode and potentially compromise the tube housing integrity.

Modern XRD/XRF labs often utilize software logs that automatically record generator usage and error codes. Reviewing these logs helps identify intermittent faults that might not appear during a visual inspection. If a survey meter detects radiation above background levels in an area designated as safe, the operator must immediately shut down the system. They must then tag it out of service. Resuming operations can only occur after a qualified expert rectifies the shielding breach or equipment fault. This rigorous approach to maintenance ensures that the protective measures designed into the system remain effective throughout the equipment's lifecycle.

Ensuring effective radiation protection in XRD/XRF labs

Prioritizing safety in X-ray analysis environments ensures long-term operational success and personnel well-being.

By strictly adhering to regulatory frameworks, maintaining robust engineering controls, and fostering a culture of continuous training, laboratory managers effectively mitigate the risks associated with ionizing radiation. The successful implementation of these radiation protection protocols in XRD/XRF labs not only satisfies legal requirements. It also creates a confident, efficient workforce capable of conducting advanced materials research without compromising health.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.