Laboratory cold storage supports research continuity, sample integrity, and operational reliability. Yet many organizations overlook the hidden waste that accumulates inside lab fridges and freezers—expired reagents, duplicated samples, overloaded units, and unnecessary energy consumption. Addressing these invisible losses helps labs strengthen quality, reduce costs, improve laboratory energy efficiency, and extend equipment life.

Reducing hidden waste in laboratory cold storage

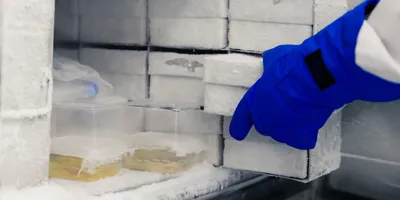

Hidden waste in laboratory cold storage often begins with limited visibility into what is stored, why it is stored, and how long it should remain on hand. Inventory inefficiency can lead to reagents expiring before use, duplicate orders, or samples being kept “just in case” without defined review criteria. In many facilities, storage decisions accumulate over time, creating cluttered shelves and inconsistent documentation that complicates lab freezer inventory management.

Structured inventory practices help reduce these risks. Barcode or RFID tracking, standardized naming conventions, and periodic sample audits support clearer ownership and prioritization. Labs that align storage decisions with retention guidelines, disposal criteria, and documented chain-of-custody practices can reduce overstocking and improve space utilization across laboratory cold storage units.

Improving laboratory energy efficiency in ultra-low-temperature freezers

Energy and equipment strain represent another source of hidden waste. When freezers are overfilled, airflow becomes restricted, and compressors work harder to maintain temperature. Frost buildup can decrease cooling efficiency, while aging gaskets and poor maintenance increase energy draw and reduce reliability. These issues compound in ultra-low-temperature (ULT) freezers, which already operate at high energy loads and require careful configuration to perform efficiently.

Right-sizing temperature setpoints is an important opportunity. Increasing ULT freezer setpoints from -80 to -70 degrees Celsius can significantly reduce energy demand and mechanical strain on compressors. Where appropriate, relocating materials from ULT freezers to conventional frozen or refrigerated storage also helps free capacity and minimize load.

Maintenance and equipment choices that reduce hidden waste

Maintenance and equipment selection choices also influence hidden waste. Preventive service programs, frost-removal routines, gasket inspections, and compressor health monitoring improve performance stability and reduce costly failures. According to My Green Lab, clean heat-exchange coils and clean or replace filters to improve heat transfer and reduce energy use by up to 10 percent, particularly in systems that operate under continuous load. When replacing units, labs can evaluate products designed for tighter temperature uniformity, improved insulation, lower standby energy use, and integrated monitoring features that support proactive oversight. These attributes help lab managers balance performance needs with sustainability goals across laboratory cold storage environments.

Governance, accountability, and long-term cold storage discipline

Finally, governance and culture shape long-term success. Establishing ownership for each unit, defining review intervals for stored materials, and engaging staff in shared accountability can reduce clutter and prevent unnecessary accumulation. When laboratory cold storage programs combine inventory visibility, temperature alignment, and disciplined maintenance, labs can reduce waste while protecting sample quality and operational continuity.