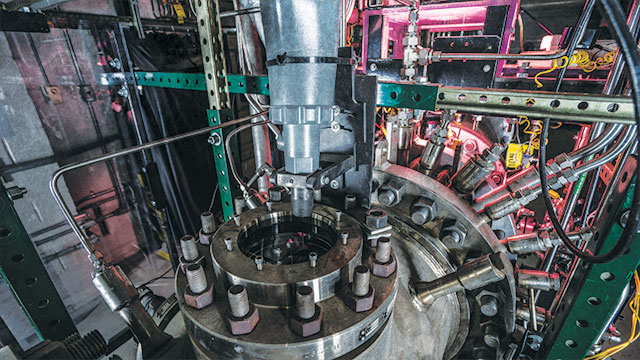

The dynamic gas turbine combustion test rig in NETL's highpressure combustion facility.

The dynamic gas turbine combustion test rig in NETL's highpressure combustion facility.

The National Energy Technology Laboratory (NETL) was established more than 100 years ago as an experimental station devoted to developing new technologies and safety procedures for the coal mining industry. Over the past century, its expertise and responsibilities have continued to expand. Today, NETL is known as the U.S. Department of Energy’s dedicated national lab focused on fossil energy research. The current mission of the lab is broader and more complex than it was at its inception—the main goal each and every day is to “discover, integrate, and mature technology solutions to enhance the nation’s energy foundation and protect the environment for future generations.”

“Every day, our team implements a broad spectrum of energy and environmental research and development programs that enable domestic coal, natural gas, and oil to economically power our nation’s homes, industries, businesses, and transportation while protecting our environment and enhancing our energy independence,” said Brian Anderson, PhD, director of NETL.

NETL encompasses multiple sites throughout the country, comprising hundreds of buildings and thousands of employees. The sheer size of NETL makes being its director sound like an intimidating task, but Anderson says that, just like any other laboratory director, he relies on the high-quality talent and skills of a wide range of experts to help execute projects and conduct hands-on research. “We are organized for success and for advancing science in the fossil energy research arena. That means regular communication and an open door dictate how we approach challenges,” explained Anderson.

Increasing energy demands

One of NETL’s primary challenges is solving the world’s increasing energy needs. By 2050, the world’s population is expected to reach 9.6 billion, and much of that growth will be seen in developing countries. This expected increase in population, as well as increasing standards of living for people in developing countries, will contribute to an even greater demand on energy resources. Currently, oil, gas, and coal collectively account for the majority of global primary energy consumption. While alternative energy options are being explored, it is still crucial to find ways to improve the efficiency of the current technologies we rely on. “The nation’s energy challenges require new technologies that allow us to use our most abundant natural resource—fossil energy—in an environmentally responsible and efficient manner for decades to come as we continue to pursue alternative energy sources,” explained Anderson. For NETL, this means finding ways to drastically reduce carbon dioxide from our power-producing capabilities, safely store captured carbon dioxide, increase the efficiency of existing and new power plant components with new materials and technologies that allow them to operate at greater temperatures and pressures, find effective ways to recover rare earth elements from energy production and by-products, increase levels of oil and gas production with new approaches, and convert carbon dioxide into useful chemicals for new products. Broadly speaking, NETL’s fossil energy R&D efforts are concentrated into three groups—coal, oil and natural gas, and energy and technology development.

Coal

In the coal sector, researchers are looking for ways to capture carbon from coal-fired power plants and industry, as well as develop safe and effective ways to store the captured carbon. Developing advanced energy systems and new alloys and parts—all of which will better use fossil fuel resources at higher temperatures and pressures—is another role. They are also interested in transformative power generation that improves existing power plants.

Oil and natural gas

NETL experts are finding better ways to recover more resources from unconventional oil and gas deposits through enhanced oil recovery. Improving the safety and efficiency of the way we collect oil and gas from offshore deepwater deposits is also a priority.

Energy and technology development

This department carries out initiatives for renewable power, sustainable transportation, and grid modernization, but also includes cybersecurity, energy security, and emergency response. For example, NETL sent response teams during each of the most recent U.S. hurricanes to help regions reconnect with power sources. “All this work is important because indications are that fossil energy will remain a vital part of the world’s energy mix for decades to come. It is incumbent for a responsible society to make sure that we pursue those resources while protecting the environment, lowering costs, and keeping the nation’s energy security strong,” said Anderson.

Lab Management Certificate

The Lab Management certificate is more than training—it’s a professional advantage.

Gain critical skills and IACET-approved CEUs that make a measurable difference.

Partners

As the only DOE national lab to be both governmentowned and operated, NETL can accelerate its research efforts through unique partnerships with industry, academia, and the private sector. “Fostering connections and forming collaborations through research partnerships and licensing agreements is the route to realizing the true value of technology and encouraging entrepreneurship in the United States,” Anderson said. One recent example of the impact that successful partnerships can have was announced by NETL in December 2018, as a result of collaborating with the Marcellus Shale Engineering and Environment Laboratory (MSEEL). The research partnership produced data from three years’ worth of research that will guide more extensive new testing at a second well site. According to Anderson, the work will advance hydraulic fracture simulation techniques that were pioneered by NETL researchers years ago. A key objective of the field test is to develop advanced completion capabilities that can be applied to other areas of the Marcellus Shale Play to improve resource recovery efficiency. The project will yield a tool set and analytical techniques that can be used on individual wells or pads to improve future resource recovery efficiency throughout the region.

The lab also has at its disposal a variety of unique equipment, such as experimental smelters and foundries for alloy development in Albany, OR, and specialty sites like the infrared spectroscopy test facility and mobile air-monitoring lab based in Pittsburgh, PA.

As NETL continues to grow and evolve, Anderson envisions expanding existing partnerships and building new ones to continue to drive innovation. He also hopes to develop and promote evolving NETL technologies for recovery of rare earth elements from coal, coal by-products, and water resources for use by U.S. industries for consumer products and defense technologies. “NETL remains a dynamic research facility that maintains equipment and research capability focused on the energy research challenges of the 21st century,” said Anderson.

A view of NETL’s Morgantown, WV facility.Credit for all photos: NETL A view of NETL’s Morgantown, WV facility.Credit for all photos: NETL |  Director Brian Anderson during a November 2018 visit to the Albany, OR site. Director Brian Anderson during a November 2018 visit to the Albany, OR site. |

NETL’s Chemical Looping Reactor in Morgantown, WV. NETL’s Chemical Looping Reactor in Morgantown, WV. | |

Samples of cored Marcellus shale on display for lab tour visitors. Samples of cored Marcellus shale on display for lab tour visitors. |  NETL’s ReACT facility is “fuel flexible,” meaning researchers are able to experiment with a wide range of fuel materials—from gaseous hydrocarbon fuel material to biomass—with the ultimate goal of enabling more power generation with fewer emissions. NETL’s ReACT facility is “fuel flexible,” meaning researchers are able to experiment with a wide range of fuel materials—from gaseous hydrocarbon fuel material to biomass—with the ultimate goal of enabling more power generation with fewer emissions. |