Characterizing the rheology of environmental slurries is a fundamental requirement for optimizing transport pipelines, designing tailings management facilities, and ensuring the efficiency of wastewater treatment operations. Laboratory professionals must accurately measure flow properties to predict how these complex suspensions behave under varying conditions of stress and shear. The study of the rheology of environmental slurries provides critical data on viscosity, yield stress, and thixotropy, which directly influence pump selection and energy consumption. Failure to account for non-Newtonian behavior in these fluids can result in pipeline blockages, equipment failure, and environmental compliance violations.

Understanding non-Newtonian flow behavior in environmental slurries

Environmental slurries exhibit complex non-Newtonian flow behavior that distinguishes them from simple fluids like water or oil. Most environmental suspensions, including dredging muds, mining tailings, and sewage sludge, resist flow until a specific stress threshold is exceeded. This resistance is defined as the yield stress, a parameter that dictates the minimum energy required to initiate movement within a pipeline or settling tank.

The relationship between shear stress and shear rate in these materials is rarely linear. As the shear rate increases, the viscosity of the slurry typically decreases, a phenomenon known as shear-thinning or pseudoplasticity. Laboratory analysis confirms that shear-thinning behavior facilitates easier pumping at high flow rates but requires careful calculation for start-up pressures.

Mathematical models are essential for describing these flow curves. The Bingham Plastic model and the Herschel-Bulkley model are the most frequently used equations to quantify the rheology of environmental slurries. These models account for both the yield stress and the curvature of the flow profile, allowing engineers to size pumps accurately.

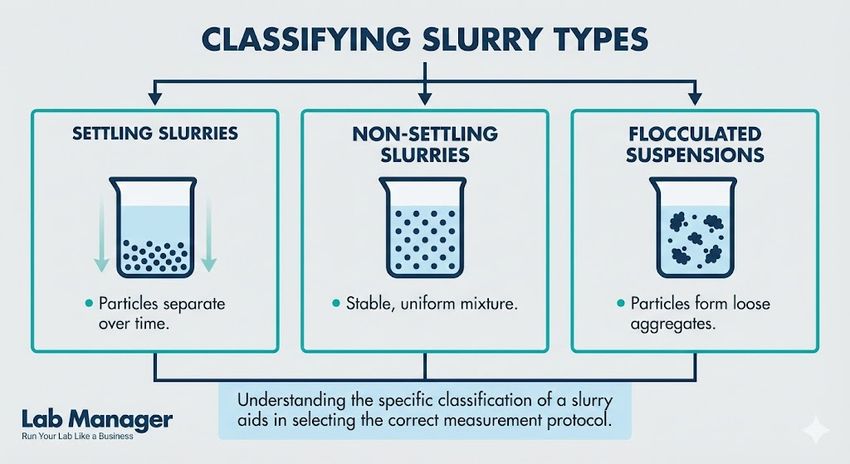

This Lab Manager infographic breaks down the three primary classifications of slurries—settling, non-settling, and flocculated suspensions—to help lab professionals identify particle behavior and select the most accurate measurement protocols for their specific sample types.

GEMINI (2026)

Classifying slurry types

Understanding the specific classification of a slurry aids in selecting the correct measurement protocol.

- Settling slurries: These contain coarse particles that settle rapidly when flow stops, requiring constant agitation during measurement.

- Non-settling slurries: These consist of fine particles that form stable suspensions, often exhibiting high viscosity and significant yield stress.

- Flocculated suspensions: These are influenced by chemical additives that create network structures, increasing thixotropy and time-dependent behavior.

Key rheological parameters for optimizing transport pipelines

Yield stress is the most significant rheological parameter for the design of transport and storage systems for environmental waste. It determines the maximum static pile height in dry stacking operations and the restart pressure required for pipelines after a shutdown. Accurate measurement of yield stress prevents catastrophic settling and ensures that material remains mobile during processing.

Viscosity measurements provide data on the resistance to flow once the material is in motion. For environmental slurries, apparent viscosity is not a single number but a function of the shear rate applied during transport. Laboratory professionals must measure viscosity over a range of shear rates relevant to the actual process conditions, such as pumping or mixing.

Thixotropy describes the time-dependent structural breakdown of a slurry under constant shear. Many environmental sludges typically exhibit thixotropic behavior, meaning they become thinner the longer they are agitated. Understanding the recovery time of this structure is vital for predicting how a slurry will behave after it has been deposited in a tailings dam or holding tank.

Operational impacts of rheology

Correctly identifying these parameters prevents common operational failures.

- Pipeline sedimentation: If the wall shear stress drops below the yield stress, solids will settle and block the pipe.

- Pump cavitation: High viscosity at the pump inlet can cause pressure drops that damage impellers.

- Screening efficiency: The flow rate through dewatering screens depends heavily on the viscosity of the liquid phase.

Research published in the Journal of Environmental Management, such as this 2018 study highlights that modifying rheological properties (e.g., moisture content) can drastically reduce pumping head and power requirements in sludge transport. Similarly, guidelines from the U.S. Environmental Protection Agency (EPA), specifically the Process Design Manual for Sludge Treatment and Disposal, emphasize the importance of viscosity monitoring in maximizing the efficiency of biosolids processing and pumping.

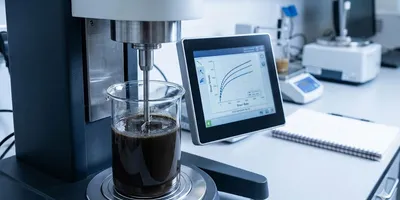

Best practices for measuring slurry rheology with rotational rheometers

Rotational rheometers equipped with appropriate geometries are the standard instruments for analyzing the rheology of environmental slurries. Unlike simple viscometers, rheometers can control shear stress and shear rate precisely to generate full flow curves. The choice of measurement geometry is critical to obtaining valid data, as incorrect setups can lead to wall slip or phase separation.

Vane geometries are often preferred over concentric cylinders or cone-and-plate systems for slurries containing large particles. The vane rotor minimizes the disruption of the sample structure during insertion and prevents the formation of a depleted liquid layer at the rotor surface. This configuration is particularly effective for measuring the static yield stress of thick, paste-like sludges.

Wall slip is a pervasive source of error when measuring smooth-walled geometries. This phenomenon occurs when the liquid phase separates from the solid phase near the sensor wall, resulting in an underestimation of viscosity. Using roughened or serrated geometries helps interlock the fluid with the sensor surface, ensuring that the bulk material is being sheared rather than just the solvent layer.

Addressing particle settling

Sedimentation during measurement distorts data and leads to poor reproducibility.

- High-shear conditioning: Pre-shearing the sample can homogenize the mixture before the test begins.

- Fast measurement protocols: Ramping shear rates quickly can capture data before significant settling occurs.

- Helical rotors: specialized geometries keep particles suspended during the measurement process.

How solids concentration and chemical properties affect slurry rheology

Solids concentration is the primary variable affecting the viscosity and yield stress of a slurry. As the volume fraction of solids increases, particle-particle interactions become more frequent, causing an exponential rise in flow resistance. Laboratory testing often involves creating concentration profiles to determine the maximum pumpable limits for a specific waste stream.

Particle size distribution (PSD) plays a complex role in determining flow properties. Generally, finer particles contribute more to viscosity and yield stress due to their high specific surface area and inter-particle forces. Conversely, a broad distribution of particle sizes can sometimes reduce viscosity, as smaller particles fill the voids between larger ones, lubricating the flow.

The chemical environment, particularly pH and ionic strength, significantly alters the rheological state of environmental slurries by modifying the zeta potential of the particles. Changes in pH can shift the surface charge, leading to either dispersion (stable, lower viscosity) or aggregation (flocculated, higher yield stress). In wastewater treatment, coagulants are intentionally added to manipulate this potential, promoting flocculation and improving dewatering efficiency.

Temperature and pressure effects

External environmental factors also modify flow behavior.

- Temperature: Viscosity generally decreases as temperature rises, which is relevant for deep-well injection or outdoor tailings lines.

- Pressure: While slurries are often treated as incompressible, entrained air in sludge can make rheology pressure-dependent.

- Shear history: The mechanical handling of the sample prior to testing affects the measured result, necessitating standardized sampling protocols.

Studies in Water Research, including the comprehensive critical review by Eshtiaghi et al. (2013), indicate that variations in pH and thermal history can drastically alter the yield stress of activated sludge. Furthermore, the International Organization for Standardization (ISO) provides protocols, such as ISO 3219-1:2021, for rotational rheometry to minimize the variability caused by thermal and mechanical history.

Why shear history affects data accuracy in thixotropic slurries

Shear history refers to the mechanical stress a sample experiences prior to rheological testing, which significantly alters the measured viscosity and yield stress of thixotropic slurries. When environmental slurries are pumped, stirred, or transported to the laboratory, their internal microstructural network is partially broken down. If a sample is tested immediately after handling without a standardized resting period, the resulting data will underestimate the material's true structural strength and static yield stress. Laboratory professionals must implement consistent pre-shear and rest protocols to erase this "memory" and ensure that measurements reflect the material's equilibrium state or its state at a specific process stage.

Conclusion: Improving waste management efficiency with accurate rheology

Comprehensive analysis of the rheology of environmental slurries provides the data necessary to engineer safe, efficient, and compliant waste management systems. By accurately defining yield stress, viscosity, and thixotropic behavior, laboratories enable engineers to design pipelines that resist clogging and pumps that operate within their optimal efficiency curves. The integration of robust measurement protocols, utilizing vane geometries and wall-slip prevention techniques, ensures that the data generated reflects the true nature of the material. Ultimately, a deep understanding of these rheological properties minimizes the environmental risk associated with mining tailings, dredging operations, and wastewater treatment.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.