Modern forensic laboratories increasingly prioritize non-destructive testing methods. This shift makes the integration of XRD/XRF in trace evidence analysis a critical standard for reliable material characterization. These complementary techniques allow forensic scientists to determine both the elemental composition and the specific crystalline phases of minute samples without altering their physical state. This preservation is essential when evidence quantities are limited. By utilizing X-ray fluorescence (XRF) for elemental profiling and X-ray diffraction (XRD) for compound identification, laboratories can generate robust data sets that withstand rigorous legal scrutiny. This article explores the scientific principles, operational workflows, and distinct advantages of applying these X-ray technologies to complex forensic investigations involving soils, explosives, illicit drugs, and transfer evidence.

Principles of X-ray fluorescence for screening in trace evidence analysis

X-ray fluorescence serves as a rapid, non-destructive screening tool that provides immediate elemental data for unknown substances found at crime scenes. XRF spectrometry works by bombarding a sample with high-energy X-rays. This bombardment dislodges inner-shell electrons from the atoms within the material. As outer-shell electrons fall to fill these vacancies, they release energy in the form of fluorescent X-rays characteristic of specific elements. This process allows analysts to determine the elemental signature of a sample. Detection ranges from sodium to uranium, often with minimal sample preparation.

In the context of XRD/XRF in trace evidence analysis, XRF is particularly valuable for differentiating materials that appear visually identical but possess distinct chemical makeups. Glass fragments, for example, often share similar refractive indices and densities. However, trace elemental analysis via micro-XRF can reveal subtle differences in manufacturing additives or impurities. This allows examiners to associate a fragment with a specific source or exclude it entirely.

X-ray Fluorescence (XRF) is a vital tool for non-destructive analysis in criminal investigations.

GEMINI (2026)

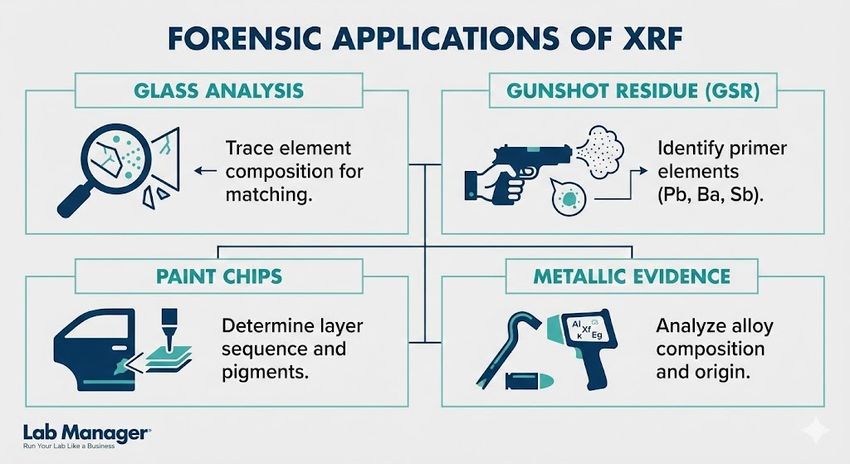

Forensic applications of XRF include:

- Glass analysis: Comparing ratios of calcium, iron, and magnesium to match fragments from hit-and-run scenes.

- Gunshot residue (GSR): detecting lead, barium, and antimony residues on hands or clothing (complementing SEM-EDS analysis).

- Paint chips: Identifying inorganic pigments and metallic additives in automotive paints.

- Metallic evidence: Determining the alloy composition of counterfeit coins or fractured tools.

Micro-XRF provides a standardized approach for the forensic comparison of glass. This approach aligns with standard practices like ASTM E2926. It also follows guidelines historically supported by the Scientific Working Group for Materials Analysis (SWGMAT), now transitioned to the Organization of Scientific Area Committees (OSAC). The technique's non-destructive nature ensures that the original sample remains available for subsequent DNA testing or refractive index analysis. This capability preserves the chain of custody. Furthermore, the speed of XRF screening helps laboratories reduce backlogs. Analysts can quickly eliminate non-probative samples before engaging in more time-consuming confirmation methods.

X-ray diffraction for phase identification in trace evidence analysis

While XRF provides an elemental inventory, X-ray diffraction offers the unique ability to identify the specific crystalline compounds and phases present in a sample. XRD operates on the principle of Bragg’s Law. Here, X-rays scattered by the crystal lattice of a material interfere constructively to produce a unique diffraction pattern. This "fingerprint" allows the analyst to distinguish between compounds that share the same elemental composition but differ in crystal structure (polymorphism).

For XRD/XRF in trace evidence analysis, this distinction is often crucial. For instance, calcium carbonate exists as both calcite and aragonite. XRF would identify calcium and oxygen in both. However, XRD distinguishes the specific mineral phase. This distinction can indicate whether a soil sample originated from a coastal environment (aragonite) or a limestone quarry (calcite). This level of specificity is vital for linking suspects to specific geographic locations based on soil transfer on shoes or tires.

Key advantages of XRD in forensics include:

- Polymorph differentiation: Distinguishing between different crystal forms of titanium dioxide (rutile vs. anatase) in paint evidence.

- Drug identification: Identifying diluents, cutting agents, and specific salt forms of illicit substances.

- Explosives analysis: Characterizing oxidizers and fuel components in post-blast residues.

- Mixture resolution: Deconvoluting complex mixtures of minerals in forensic soil analysis.

The Scientific Working Group for the Analysis of Seized Drugs (SWGDRUG) recognizes XRD as a Category A analytical technique, offering the highest level of selectivity for structural elucidation. Unlike color tests or basic microscopy, XRD provides definitive structural data. This data can confirm the presence of a specific chemical substance. This capability is particularly relevant when analyzing novel psychoactive substances (NPS), where the specific arrangement of atoms defines the legality and toxicity of the compound. By integrating XRD into the workflow, the laboratory ensures that the chemical identification is based on the immutable physical structure of the material.

Synergistic use of XRD/XRF in trace evidence analysis workflows

The true power of these technologies lies in their combination. Data from one method validates and refines the findings of the other. Utilizing XRD/XRF in trace evidence analysis creates a comprehensive analytical profile that neither technique could achieve in isolation. XRF provides the elemental "what," limiting the search parameters for the XRD database. XRD provides the structural "how," confirming the specific compounds formed by those elements.

This synergy is often applied in the analysis of automotive paint systems. Automotive paint consists of multiple layers—clear coat, base coat, primer, and electrocoat—each containing specific binders, pigments, and extenders. An XRF analysis might detect titanium, iron, and talc-related elements (magnesium, silicon) in a paint smear. However, it cannot confirm the specific pigment types. By following up with XRD, the examiner can confirm the presence of rutile (titanium dioxide), hematite (iron oxide), and talc (magnesium silicate hydroxide). This combination dramatically increases the evidentiary value of the sample. The probability of a random match across both elemental and phase characteristics is significantly lower.

Workflow Integration for Trace Evidence:

Stage | Action | Technique | Outcome |

|---|---|---|---|

1 | Visual Inspection | Microscopy | Morphology, color, layer structure assessment. |

2 | Elemental Screening | Micro-XRF | Identification of major and minor elements; exclusion of non-matches. |

3 | Phase ID | Micro-XRD | Identification of crystalline compounds; confirmation of pigments/minerals. |

4 | Data Synthesis | Analysis Software | Final report combining elemental and structural profile. |

The importance of sample preservation and non-destructive analysis

A primary challenge in forensic science involves the destructive nature of many analytical techniques. Destructive methods consume the sample and prevent re-analysis by opposing counsel. XRD/XRF in trace evidence analysis mitigates this issue through inherent non-destructive capabilities. X-rays interact with the sample without altering its chemical bonding or physical mass. Consequently, the evidence remains pristine. This feature is critical when dealing with "trace" quantities, often particles less than 50 micrometers in size. In these cases, the entire sample might be required for a single test. Preserving the evidence ensures compliance with legal standards regarding the right to independent testing. It also maintains the integrity of the chain of custody. Furthermore, non-destructive analysis allows the same sample to undergo subsequent testing, such as Raman spectroscopy or DNA extraction. This maximizes the information yield from a single piece of evidence.

Instrumentation advancements for XRD/XRF in trace evidence analysis

Recent technological advancements have miniaturized X-ray instrumentation. This moves capabilities from the benchtop to the field. Portable XRF (pXRF) and portable XRD (pXRD) analyzers now allow crime scene investigators to perform preliminary screenings in situ. Laboratory-grade instruments offer superior resolution and lower limits of detection. However, field units provide actionable intelligence that can guide the investigation immediately.

For XRD/XRF in trace evidence analysis, the evolution of micro-focused sources is particularly significant. Benchtop micro-XRF units can now focus X-ray beams down to spot sizes as small as 10 micrometers. This precision allows analysts to scan individual layers of a paint chip cross-section or specific grains within a soil mixture. Similarly, advances in detector technology for XRD have reduced data acquisition times from hours to minutes, improving laboratory throughput.

The integration of automated sample changers and sophisticated spectral matching software has further streamlined the process. Modern software packages can overlay XRF and XRD data. They automatically cross-reference elemental peaks with diffraction patterns to suggest candidate phases. This automation reduces the cognitive load on the analyst and minimizes the potential for human error during data interpretation. However, despite these automated tools, the expertise of the forensic scientist remains essential for validating results and interpreting complex mixtures found in real-world samples.

Laboratories looking to adopt these advancements must validate methods according to ISO/IEC 17025 standards. Validation ensures that the specific instrument configuration—whether a high-powered benchtop system or a handheld field unit—produces reliable, reproducible results for the specific types of evidence encountered in casework.

Conclusion on the role of XRD/XRF in trace evidence analysis

The combined application of XRD/XRF in trace evidence analysis represents a gold standard for non-destructive forensic characterization. Laboratories leverage the elemental specificity of X-ray fluorescence and the structural definition of X-ray diffraction. This allows them to resolve complex analytical questions involving glass, paint, soil, and illicit substances. These techniques provide high-value, court-admissible data while strictly adhering to evidence preservation protocols. As instrumentation continues to advance in sensitivity and portability, the role of X-ray analysis in forensics will only expand, offering greater precision in the pursuit of justice.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.