The food and beverage industry operates within a complex regulatory landscape, where consumer safety and product quality are paramount. In this environment, the role of the laboratory professional is indispensable, with a heavy reliance on precise and reliable analytical testing. The integrity of a product, from raw ingredient to finished good, is confirmed through a rigorous series of examinations. These processes are not merely about compliance; they are fundamental to brand reputation, public health, and the scientific understanding of product composition. Comprehensive food analysis provides the data necessary to make informed decisions regarding everything from nutritional labeling to the identification of contaminants. This article delves into the core principles, methodologies, and quality assurance protocols that define best practices in analytical testing within this critical sector.

Foundational Principles of Food Analytical Testing

Effective food analysis requires a diverse suite of techniques spanning multiple scientific disciplines. A single product’s journey through the laboratory may involve chemical, physical, and microbiological examinations, each providing a unique perspective on its quality and safety. This multi-disciplinary approach ensures a holistic understanding of a sample's characteristics.

- Chemical Analysis: This is the most common form of analytical testing in the food and beverage industry. It quantifies the chemical composition of a sample, including macronutrients (fats, proteins, carbohydrates), micronutrients (vits, minerals), and a wide array of additives and preservatives. Chemical analysis is also crucial for detecting chemical contaminants, such as pesticide residues, heavy metals, and mycotoxins.

- Physical Analysis: This category of tests evaluates the physical properties of a product. Key parameters include texture, viscosity, color, and particle size. These tests are essential for ensuring product consistency and quality from batch to batch. For example, the viscosity of a sauce or the firmness of a fruit can be measured to meet specific product specifications.

- Microbiological Analysis: This is a critical component of food safety. It involves the detection and enumeration of microorganisms that could pose a health risk, such as bacteria like Salmonella, E. coli, and Listeria. Microbiological analysis also assesses spoilage organisms that impact a product's shelf life.

The synergy between these analytical disciplines allows laboratories to construct a complete profile of a food product, verifying its adherence to both regulatory requirements and internal quality standards.

Advanced Analytical Testing Techniques for Food Science

Modern analytical testing has been revolutionized by advanced instrumentation that offers unparalleled sensitivity and specificity. Chromatography and spectroscopy are the two most prominent technique families used in food laboratories for both routine and investigative analysis. These methods allow for the separation, identification, and quantification of complex mixtures.

Chromatographic Techniques

Chromatography separates components of a mixture based on their differential distribution between a stationary phase and a mobile phase.

Technique | Principle | Common Food Applications |

|---|---|---|

Separates compounds based on polarity using a liquid mobile phase. | Vitamin analysis, mycotoxin detection, sugar and additive quantification, and pesticide residue analysis. | |

Separates volatile compounds, which are then identified by mass spectrometry. | Detection of flavors and aromas, pesticide residues, and fatty acid profiling. | |

Ion Chromatography (IC) | Separates ions and polar molecules. | Quantification of nitrates, nitrites, and other inorganic anions. |

Spectroscopic Techniques

Spectroscopy measures the interaction between electromagnetic radiation and matter to determine a substance's identity and concentration.

Technique | Principle | Common Food Applications |

|---|---|---|

Atomic Absorption Spectroscopy (AAS) | Measures the absorption of light by free atoms. | Heavy metal analysis (e.g., lead, cadmium) in food. |

Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) | Ionizes a sample in plasma to identify and quantify elements. | Trace metal analysis, mineral content, and authenticity studies. |

Nuclear Magnetic Resonance (NMR) Spectroscopy | Measures the magnetic properties of atomic nuclei. | Authentication of products like honey and olive oil, and comprehensive metabolomics. |

The integration of these analytical testing platforms enables laboratories to tackle complex analytical challenges, from confirming the authenticity of a premium olive oil to detecting trace-level contaminants that could compromise food safety.

Ensuring Food Safety: Analytical Testing for Contaminants

The primary mandate of analytical testing in the food industry is safeguarding public health. This requires a dedicated focus on the detection of harmful contaminants and the identification of adulterated products. Contaminants can be chemical, microbiological, or physical, while adulteration involves the deliberate alteration of a product to misrepresent its quality or origin.

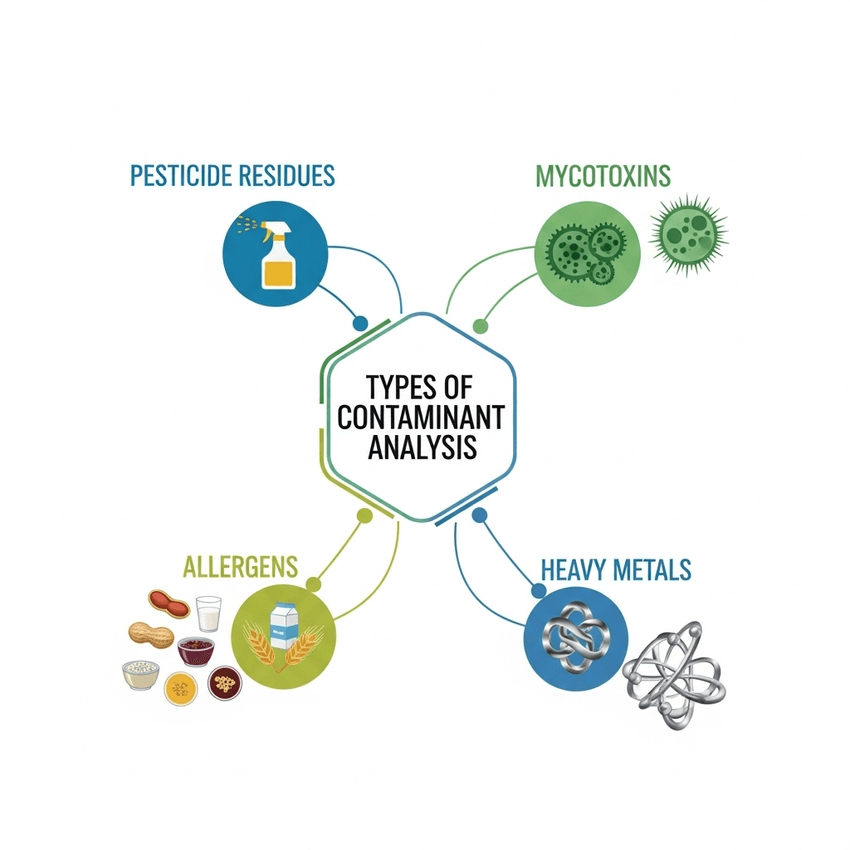

Types of Contaminant Analysis

Contaminants range from allergens to mycotoxins.

GEMINI (2025)

- Pesticide Residues: Agricultural products must be monitored for pesticide residues to ensure they are below maximum residue limits (MRLs). Techniques like GC-MS and LC-MS/MS are critical for this high-sensitivity analysis.

- Mycotoxins: These toxic compounds are produced by certain fungi and can contaminate crops. Aflatoxins, ochratoxin A, and deoxynivalenol are frequently monitored using methods like HPLC with fluorescence detection.

- Allergens: The presence of undeclared allergens in packaged food is a significant public health risk. ELISA (Enzyme-Linked Immunosorbent Assay) and PCR (Polymerase Chain Reaction) are commonly used to detect trace amounts of allergens like peanuts, soy, and gluten.

- Heavy Metals: Lead, mercury, arsenic, and cadmium can enter the food chain through contaminated soil or water. ICP-MS provides the high sensitivity required to quantify these elements at sub-trace levels.

Adulteration and Food Fraud

The global supply chain creates opportunities for fraudulent practices, such as the substitution of high-value ingredients with cheaper alternatives. For example, the use of cheaper oils in olive oil products or the substitution of fish species in seafood. Isotope Ratio Mass Spectrometry (IRMS) and NMR spectroscopy are powerful tools for establishing a product’s geographic origin and confirming its authenticity. The continuous evolution of fraudulent practices necessitates a proactive and technologically advanced approach to food analysis.

Precision and Reliability in Food Analytical Testing

In any laboratory, the validity of a result is directly tied to the rigor of its quality assurance (QA) and quality control (QC) programs. For analytical testing in the food and beverage industry, where public health is at stake, this is an absolute necessity. A robust QA/QC framework ensures that all data generated is accurate, reproducible, and legally defensible.

Method Validation

Before a new method is implemented for routine analysis, it must undergo a thorough validation process. This establishes the method’s suitability for its intended purpose by evaluating key performance parameters:

- Accuracy: The closeness of the measured value to the true value.

- Precision: The degree of agreement among a series of measurements.

- Specificity: The ability of the method to measure only the target analyte.

- Limit of Detection (LOD) and Limit of Quantitation (LOQ): The minimum concentration of an analyte that can be reliably detected and quantified.

- Linearity: The method's ability to produce results proportional to the analyte's concentration.

- Robustness: The method's ability to remain unaffected by small, deliberate variations in method parameters.

Internal and External Controls

Internal QC procedures, such as the use of control charts and replicate analysis, are essential for monitoring method performance. Laboratories also participate in external proficiency testing programs, where they analyze blind samples and compare their results to those of other labs. This provides an independent assessment of a laboratory’s competence and helps maintain accreditation. The adherence to international standards, such as ISO/IEC 17025, provides a framework for competence in the testing and calibration of laboratories. The commitment to these principles of quality control ensures that every result is reliable, and every decision based on that data is sound.

The Future of Analytical Testing in Food Science

The field of food and beverage analytical testing is a dynamic and essential component of a safe and reliable global food supply. It is a multi-faceted discipline that demands a high degree of technical expertise, a deep understanding of scientific principles, and an unwavering commitment to quality. From foundational chemical and microbiological assessments to the use of advanced chromatographic and spectroscopic platforms, the work performed in the laboratory directly impacts consumer health and product integrity. The continued evolution of technology, combined with a steadfast focus on rigorous quality assurance protocols, reinforces the professional significance of this work. For laboratory professionals, maintaining a mastery of these techniques and principles is paramount to meeting the complex challenges and safeguarding the future of the food and beverage industry.

Frequently Asked Questions

What is the difference between food quality control and food safety?

Food safety focuses on the absence of hazards that could cause consumer illness or injury. This includes microbiological pathogens, chemical contaminants, and physical foreign objects. Analytical testing for food safety is often mandated by law and involves a zero-tolerance policy for certain hazards. It is a non-negotiable aspect of production. In contrast, food quality control pertains to the non-safety attributes of a product, such as flavor, texture, appearance, nutritional content, and consistency. While not a direct threat to health, food quality control is essential for meeting consumer expectations and brand standards. Both are vital for food production and rely on accurate analytical testing, but they serve distinct purposes.

How are new analytical methods validated for food testing?

Method validation is a systematic process that confirms an analytical procedure is suitable for its intended purpose. It involves a series of tests to evaluate the method's performance characteristics. This includes assessing its accuracy by analyzing certified reference materials, its precision through replicate analysis, and its specificity to ensure no interfering compounds are measured. The method’s linear range and the limits of detection and quantitation are also determined. The validation data must demonstrate that the new method is capable of providing accurate and reliable results for the specific food matrix and analyte of interest, ensuring confidence in the data generated from the analytical testing procedure.

What are some common challenges in food analytical testing?

The complexity of food matrices presents a significant challenge. A single sample can contain thousands of compounds, making the isolation and quantification of a specific analyte difficult. Sample preparation is often a time-consuming and critical step, as it can be a major source of error. The diversity of food products, from high-fat dairy to high-sugar beverages, requires laboratories to have a wide range of specialized methods and instruments. Additionally, the constant emergence of new contaminants and fraudulent practices necessitates the continuous development and validation of new analytical testing methods. These challenges demand a high level of expertise and technical adaptability within the laboratory.

How does technology impact the future of food analytical testing?

Technological advancements are continuously shaping the field of analytical testing. Automation and robotics are streamlining sample preparation and increasing sample throughput, reducing human error and improving efficiency. Miniaturized sensors and portable analytical devices are enabling on-site and real-time testing, allowing for quicker interventions in the supply chain. Data management and bioinformatics are becoming increasingly important for processing the vast amount of information generated by modern instruments. The integration of advanced techniques, such as non-targeted screening methods, will enhance the ability to detect unknown contaminants and adulterants. These innovations will ultimately lead to a more proactive and precise approach to food safety and quality.