Automated screening using differential scanning calorimetry (DSC) and thermogravimetric analysis (TGA) provides the high-throughput capability necessary for modern material characterization and quality control laboratories. Laboratories utilize automated thermal analysis to process large sample volumes with minimal operator intervention. This ensures consistent thermal history and reproducible data sets. Researchers utilize robotic autosamplers and advanced software to run continuous analysis cycles. This integration maximizes instrument utilization and reduces human error in sample handling. Automated screening protocols allow for rapid identification of thermal transitions, purity levels, and compositional stability. These benefits apply across diverse materials ranging from pharmaceuticals to polymers.

Role of robotics in automated thermal analysis workflows

Robotic autosamplers serve as the foundation of effective automated screening. They mechanically manage sample introduction and removal with high precision. An automated system typically employs a gantry or carousel-based robotic arm. It transports crucibles from a storage tray to the measurement cell to ensure exact placement on the sensor. Precise positioning is critical in DSC and TGA. The thermal contact between the sample pan and the sensor directly influences baseline quality and heat flow signal resolution.

Automated systems operate continuously, allowing laboratories to extend analytical capacity beyond standard working hours. This capability is particularly vital for stability studies where hundreds of samples must be analyzed under identical conditions. Robotics also mitigate thermal disturbances associated with manual loading. The furnace remains closed or follows a controlled opening sequence to maintain thermal equilibrium.

Running a productive lab means optimizing for both precision and personnel safety.

GEMINI (2026)

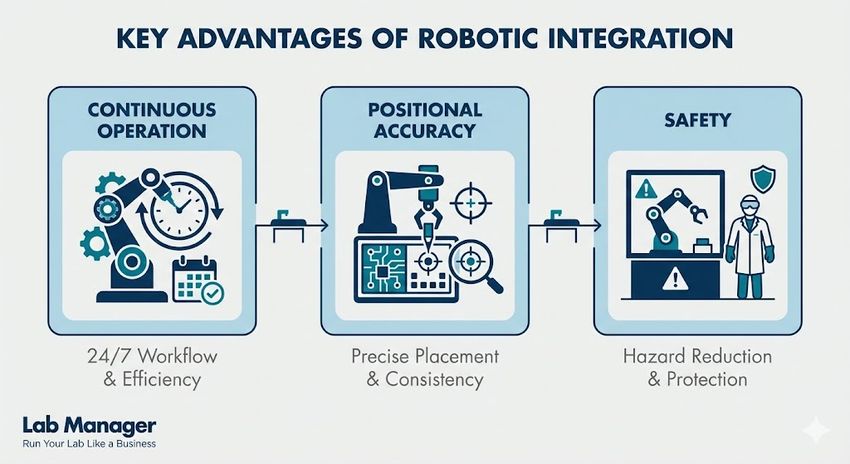

Key advantages of robotic integration include:

- Continuous operation: Instruments can run 24 hours a day, significantly increasing sample throughput.

- Positional accuracy: Robots place samples in the exact same location on the sensor every time, reducing experimental noise.

- Safety: Operators are removed from direct contact with high-temperature furnaces and potentially hazardous evolved gases.

Optimizing automated screening with DSC

Automated screening with DSC focuses on rapid determination of melting points, glass transitions, oxidative induction times (OIT), and crystallization behaviors in solid and liquid samples. High-throughput DSC protocols rely on standardized heating and cooling rates. This generates comparable data sets across large sample batches. For pharmaceutical polymorph screening, automation allows for the systematic thermal cycling of potential drug candidates. This helps identify stable and metastable forms without constant manual supervision.

Calibration verification is a critical component of automated DSC workflows. Modern software can schedule automated calibration checks using reference standards like indium or zinc at pre-set intervals within a sample queue. If a check falls outside defined tolerance limits, the system can automatically trigger a recalibration routine. Alternatively, it can pause the sequence to prevent the collection of invalid data. This intelligent feedback loop ensures that data integrity is maintained throughout long unattended runs.

Specific considerations for automated DSC include:

- Pan selection: Automated lids and hermetic sealing presses ensure pans do not deform during robotic transport.

- Baseline subtraction: Software automatically applies baseline corrections using empty pan runs scheduled within the sequence.

- Cleaning protocols: Some systems include automated "burn-off" or cleaning cycles to remove volatile condensates from the cell between analytical runs.

Conducting stability testing via automated TGA

TGA automated screening is primarily used to assess thermal stability, compositional content, and decomposition kinetics in a high-volume environment. In automated TGA workflows, the balance mechanism measures mass changes as a function of temperature or time. This provides critical data on moisture content, volatile components, and polymer filler percentages. Automation is essential for standard test methods, such as ASTM E1131, where strict adherence to heating rates and gas switching is required for reproducibility.

Gas switching plays a pivotal role in automated TGA experiments. Software-controlled mass flow controllers switch the atmosphere from inert nitrogen to oxidative air or oxygen. These switches occur at precise time points or temperature thresholds. This capability enables the automated determination of carbon black content in rubber or the thermal decomposition profiles of polyolefins without operator intervention. The precise timing of these gas switches ensures that the chemical reaction environment is consistent for every sample in the batch.

Factors influencing automated TGA success include:

- Buoyancy correction: Automated systems run blank curves to mathematically correct for buoyancy effects caused by changing gas density.

- Crucible taring: The autosampler weighs empty crucibles before the run to establish an accurate initial mass baseline.

- Ash disposal: Post-run protocols typically involve moving the crucible to a waste bin, clearing the furnace for the next sample immediately.

Managing data in automated screening systems

The sheer volume of data generated by automated screening requires robust software solutions for acquisition, storage, and interpretation. Advanced thermal analysis software employs algorithms to automatically mark transition peaks and calculate onset temperatures. It also integrates peak areas immediately after data collection. This immediate processing capability allows laboratory managers to review "pass/fail" results based on pre-defined quality control criteria rather than manually analyzing every curve.

Data integrity and traceability are paramount in regulated industries utilizing automated screening. Software platforms often include features compliant with 21 CFR Part 11, such as audit trails, electronic signatures, and secure database storage. These systems track every step of the automated process, from the moment a sample is logged into the queue to the generation of the final report. LIMS (Laboratory Information Management System) integration further streamlines the workflow by automatically transferring results from the thermal analyzer to the central laboratory database.

Effective data strategies involve:

- Automated reporting: Generating PDF or CSV reports immediately upon run completion.

- Trend analysis: Aggregating data from hundreds of runs to identify process drifts or material inconsistencies over time.

- Error handling: Smart logic that identifies failed runs (e.g., pan misuse) and flags them without stopping the entire queue.

Maintaining autosampler reliability for sample integrity

Reliability in the mechanical handling of samples is the single most critical physical factor in successful automated screening. The robotic mechanism must grip, lift, and transport delicate ceramic or aluminum crucibles without deforming them or spilling the sample material. Modern autosamplers utilize sophisticated optical sensors or force-feedback mechanisms. These sensors detect whether a pan has been successfully picked up or released. If a sensor fails to detect a pan, the system is designed to retry the operation or skip to the next position to avoid jamming the mechanism. Furthermore, the integrity of the sample prior to analysis is maintained through covered sample trays. These trays protect hygroscopic materials from absorbing ambient moisture while awaiting analysis in the queue. Maintaining this mechanical reliability requires regular preventative maintenance, including calibration of the robot arm coordinates and inspection of the gripper fingers for wear.

Conclusion: Advancing automated screening with DSC and TGA

Automated screening with DSC and TGA fundamentally changes the economics and efficiency of material characterization. Laboratories achieve high throughput and reproducibility by coupling robust robotic autosamplers with intelligent data analysis software. This level of performance is unattainable with manual operation. The ability to run continuous, unattended analysis cycles allows scientists to focus on data interpretation and method development rather than routine sample loading. As software algorithms become more sophisticated, the speed and accuracy of automated thermal analysis will continue to drive innovation in quality control and materials research.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.