The study of biodegradable polymers represents a crucial frontier in materials science, offering pathways to develop materials that can coexist more harmoniously with natural ecosystems. These materials are not merely a market trend but a complex class of polymers defined by their ability to undergo complete polymer degradation through biological processes, resulting in biomass, carbon dioxide, and water. This article provides a foundational overview of biodegradable polymers, their characteristics, and the analytical methods used to understand their behavior in a laboratory setting. A deep understanding of these principles is essential for material development, quality control, and environmental impact assessment. The rise of bioplastics and other compostable materials is reshaping industrial practices and requires a robust scientific response.

Mechanisms of Biodegradable Polymer Degradation

The term biodegradable polymers refers to a specific class of plastics that can be broken down by microorganisms such as bacteria, fungi, and algae. This process is distinct from mere fragmentation or photo-degradation, which can leave behind persistent microplastic particles. True biodegradation is a two-step process: depolymerization and mineralization.

Depolymerization is the initial stage where microbial enzymes attack the polymer chains, breaking them down into smaller, water-soluble oligomers and monomers. The efficiency of this step is highly dependent on the polymer's chemical structure, crystallinity, and the environmental conditions, including temperature, pH, and nutrient availability. For instance, the presence of hydrolyzable bonds, such as ester or amide linkages, facilitates enzymatic attack.

Following depolymerization, the resulting oligomers and monomers are assimilated by the microorganisms and fully converted into simple inorganic compounds. This final stage is known as mineralization. The end products are primarily carbon dioxide, water, and new biomass, effectively returning the material to the natural carbon cycle.

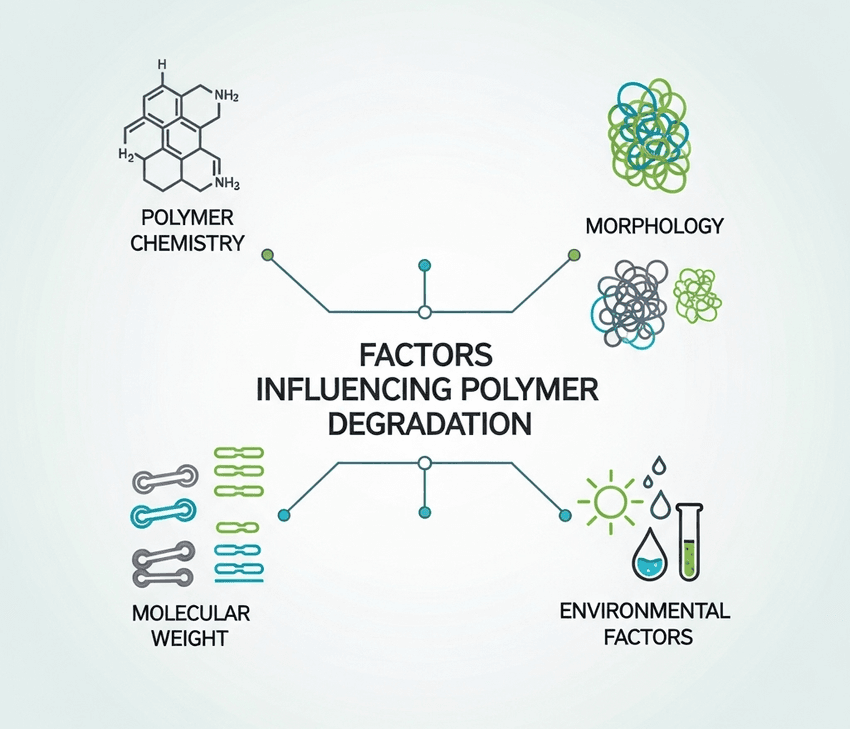

Several factors influence the rate and extent of polymer degradation, including:

Several factors influence the rate and extent of polymer degradation.

GEMINI (2025)

- Polymer Chemistry: The presence of functional groups like esters or amides.

- Morphology: Amorphous regions degrade faster than crystalline regions.

- Molecular Weight: Lower molecular weight polymers typically degrade more quickly.

- Environmental Factors: Temperature, moisture, pH, oxygen levels, and the microbial community composition.

For a material to be classified as a compostable material, it must not only biodegrade but also do so within a specific timeframe and leave no toxic residue. This requires adherence to rigorous testing standards.

Common Types of Bioplastics and Biodegradable Polymers

A diverse range of bioplastics exists, each with unique properties and applications. These materials can be synthesized from renewable resources or petroleum-based monomers, with their biodegradability stemming from their specific molecular structure. Understanding the characteristics of each class is vital for material selection and performance analysis.

1. Polylactic Acid (PLA): PLA is one of the most widely used biodegradable polymers. It is a polyester derived from fermented plant starch, such as corn or sugarcane. PLA is known for its high stiffness, transparency, and barrier properties, making it suitable for food packaging, disposable cutlery, and 3D printing filaments. However, its slow degradation rate under ambient conditions often necessitates industrial composting facilities.

2. Polyhydroxyalkanoates (PHAs): PHAs are polyesters produced by microorganisms as an energy storage mechanism. This class includes a variety of polymers with different monomeric units, which allows for a wide range of mechanical properties, from brittle to elastic. PHAs are highly biocompatible and can biodegrade in a variety of environments, including soil and marine water, making them promising eco-friendly plastics for applications like medical implants and marine debris solutions.

3. Polybutylene Adipate Terephthalate (PBAT): PBAT is a co-polyester synthesized from petroleum-based monomers. Despite its fossil-fuel origin, its chemical structure is designed to be fully biodegradable. PBAT is known for its excellent flexibility and toughness, making it a common blend component in compostable films and bags to improve their mechanical properties.

4. Polycaprolactone (PCL): PCL is a synthetic, semi-crystalline polyester. It is notable for its very low melting point and excellent processability, making it easy to blend with other polymers. PCL has a relatively fast degradation rate under a variety of conditions and is often used in biomedical applications such as drug delivery systems and tissue engineering scaffolds.

Polymer Type | Origin | Key Properties | Common Applications |

|---|---|---|---|

PLA | Bio-based | Stiff, transparent, brittle | Food packaging, 3D printing |

PHAs | Bio-based | Variable, highly biodegradable | Medical implants, marine plastics |

PBAT | Synthetic | Flexible, tough | Compostable bags, films |

PCL | Synthetic | Low melting point, processable | Medical devices, drug delivery |

Characterization and Standardization of Biodegradable Polymers

The true test of a biodegradable polymer lies in its ability to meet standardized criteria for degradation and safety. Laboratory professionals play a critical role in performing the analytical tests required to certify these materials. These tests validate claims of biodegradability and ensure the materials do not leave behind toxic byproducts.

1. Degradation Testing Standards: International and regional standards bodies, such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization), have established protocols for assessing biodegradation. Key standards include:

- ASTM D5338/ISO 14855: Measures the aerobic biodegradation of plastic materials under controlled composting conditions.

- ASTM D5511: Determines the anaerobic biodegradation of plastic materials under high-solids anaerobic-digestion conditions.

- ASTM D6691: Evaluates the aerobic biodegradation of plastics in the marine environment.

These tests typically involve placing the material in a simulated environment (e.g., compost, soil, marine water) and monitoring the evolution of carbon dioxide. The degree of mineralization is calculated by comparing the CO2 produced to the theoretical maximum from the sample's carbon content.

2. Analytical Techniques for Material Characterization: Before and after degradation, a suite of analytical techniques is used to characterize the polymer's structure and properties. These methods help to elucidate the mechanism of degradation and assess the impact on material performance.

- Thermogravimetric Analysis (TGA): Measures the change in mass of a sample as a function of temperature. TGA can be used to determine the thermal stability of the polymer and assess changes in its composition during degradation.

- Differential Scanning Calorimetry (DSC): Measures the heat flow to and from a sample as it is heated or cooled. DSC is used to determine key thermal transitions, such as glass transition temperature (Tg) and melting point (Tm), which can change as the polymer degrades.

- Gel Permeation Chromatography (GPC): Used to determine the molecular weight and molecular weight distribution of a polymer. As biodegradation proceeds, the polymer chains are broken, leading to a decrease in molecular weight. GPC is a sensitive tool for monitoring this process.

- Fourier-Transform Infrared Spectroscopy (FTIR): Provides a spectrum of absorbance or transmittance that can be used to identify functional groups within the polymer. FTIR can detect changes in the chemical structure that occur during degradation.

Challenges and the Future of Eco-Friendly Plastics

Despite significant progress, the widespread adoption of eco-friendly plastics faces several technical and economic hurdles. A major challenge is balancing biodegradability with material performance. A polymer that degrades too quickly may not be suitable for long-term applications, while one that is too stable may not meet compostability standards. The cost of production for many bioplastics remains higher than for conventional plastics, hindering market penetration.

Research is ongoing to address these challenges. Scientists are exploring new synthesis routes to create novel biodegradable polymers with enhanced properties. Blending different bioplastics or incorporating fillers is another strategy to tune mechanical properties and reduce costs. The development of advanced analytical techniques, such as real-time monitoring of microbial activity, will further refine our understanding of polymer degradation processes. Ultimately, the future of sustainable materials lies in a multidisciplinary approach, combining polymer chemistry, microbiology, and process engineering to create materials that are both high-performing and environmentally benign.

The Future of Biodegradable Polymers and Sustainable Materials

The field of biodegradable polymers is a cornerstone of modern sustainable materials science, demanding a rigorous, evidence-based approach from the laboratory community. By understanding the intricate mechanisms of polymer degradation, characterizing a wide array of bioplastics, and adhering to robust testing standards for compostable materials, laboratory professionals are at the forefront of innovation. The development of new eco-friendly plastics is not just about material substitution but about designing materials for a complete life cycle, from synthesis to final breakdown. This ongoing effort will be critical in mitigating the environmental legacy of plastics and forging a more sustainable future.

FAQ

What is the difference between biodegradable and compostable materials?

All compostable materials are biodegradable, but not all biodegradable polymers are compostable. A material is considered compostable only if it biodegrades under specific composting conditions within a set timeframe, leaving no toxic residue. Biodegradable simply means the material can be broken down by microorganisms, without specifying the time frame or conditions.

Are all bioplastics biodegradable?

No, the terms are not interchangeable. Bioplastics are plastics derived from biomass, but some, like bio-PET, have the same chemical structure as their fossil-fuel counterparts and are not inherently biodegradable. The biodegradability of bioplastics depends entirely on their specific chemical composition and molecular structure, not their renewable origin.

How are the properties of biodegradable polymers measured in a lab setting?

The properties of biodegradable polymers are measured using a variety of analytical techniques. Thermal properties are determined using DSC and TGA. Molecular weight and chain scission are analyzed with GPC, while chemical structure and functional group changes are monitored with FTIR. These methods provide critical data on material performance and degradation.

What is the main challenge in developing new eco-friendly plastics?

The primary challenge is balancing performance and biodegradability. An eco-friendly plastic must be durable enough for its intended use but also degrade efficiently at its end of life. Other challenges include the cost of production and the need for more efficient degradation in natural environments like oceans and soil, rather than just industrial composting facilities.