Particle size consistency in suspensions is the critical determinant of formulation stability, bioavailability, and manufacturing quality in pharmaceutical, chemical, and food industries. Laboratory professionals must rigorously control the particle size distribution (PSD) to prevent issues such as sedimentation, caking, and uneven dosage delivery. Variations in PSD often lead to failed regulatory inspections or compromised product efficacy, making the standardization of this parameter essential for operational success. By implementing validated characterization techniques and understanding the physical chemistry of dispersions, labs can maintain the necessary uniformity in their suspension systems.

Why is particle size consistency critical for suspension stability?

Particle size consistency directly influences the sedimentation rate and physical stability of a suspension according to Stokes’ Law. When the particle size distribution is wide or inconsistent, larger particles settle significantly faster than smaller ones, leading to rapid phase separation and the formation of hard, non-redispersible cakes. This physical instability compromises the shelf life and performance of the product, particularly in pharmaceutical formulations where dose uniformity is mandated by regulatory bodies like the FDA.

Monitoring the PSD allows formulation scientists to predict stability behavior and adjust rheological modifiers accordingly. A narrow distribution minimizes the disparity in sedimentation velocities, keeping the system homogenous for longer periods. Furthermore, controlling particle size reduces the risk of Ostwald ripening, a phenomenon where smaller particles dissolve and redeposit onto larger ones, drastically altering the suspension's properties over time.

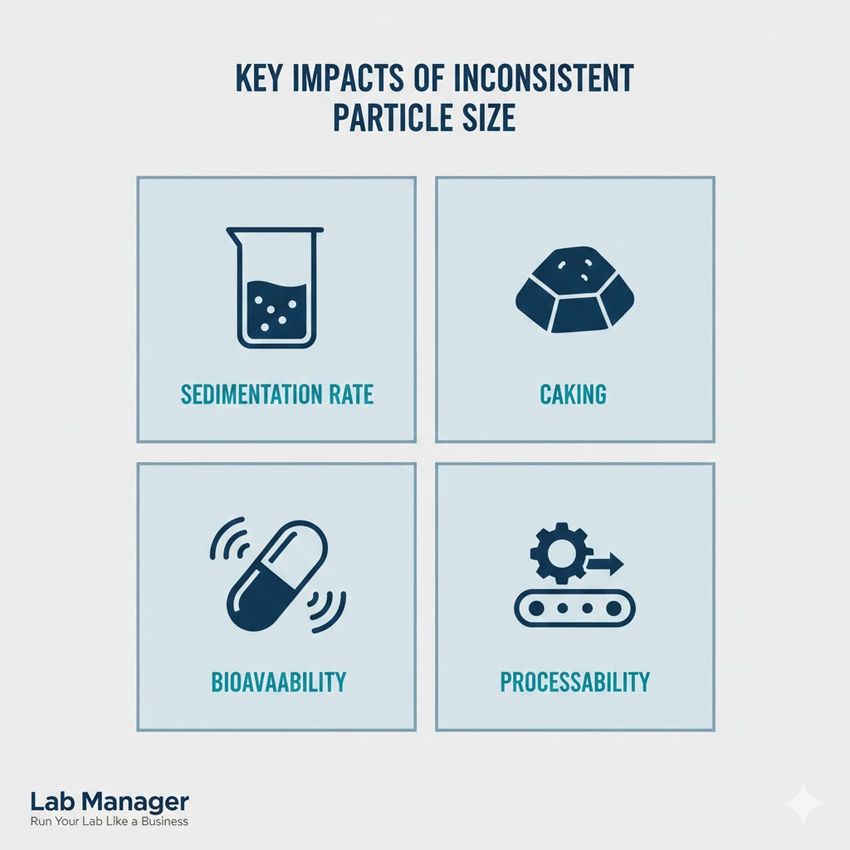

Understanding how particle size variability influences everything from chemical stability (sedimentation and caking) to therapeutic efficacy (bioavailability) and manufacturing efficiency (processability)

GEMINI (2026)

Key impacts of inconsistent particle size:

- Sedimentation Rate: Larger particles accelerate settling, causing rapid stratification of the suspension.

- Caking: Polydisperse systems often form dense sediments that cannot be easily redispersed by shaking.

- Bioavailability: In pharmaceutical suspensions, erratic particle sizes cause variable dissolution rates, leading to unpredictable therapeutic effects.

- Processability: Inconsistent slurries can clog filtration systems or nozzles during downstream processing.

References such as USP <429> Light Diffraction Measurement of Particle Size emphasize the necessity of controlling the distribution width (span) to ensure reproducibility. The International Organization for Standardization (ISO) also provides guidance in ISO 13320, detailing the methodology for laser diffraction to verify these parameters.

Which analytical techniques best measure particle size in suspensions?

Laser diffraction is the industry standard for measuring particle size consistency in suspensions ranging from sub-micron to millimeter scales. This technique relies on Mie theory to calculate particle size distributions based on the angular scattering of light, providing rapid and statistically significant data. For suspensions containing particles below 1 micron, Dynamic Light Scattering (DLS) is frequently employed to measure hydrodynamic radius via Brownian motion analysis.

Selecting the correct technique depends heavily on the expected size range and the concentration of the dispersed phase. While laser diffraction offers a broad dynamic range, it requires precise optical models and refractive index data to generate accurate results. Conversely, automated imaging techniques allow for the visualization of particle shape, which helps distinguish between agglomerates and primary particles.

Comparison of common particle sizing techniques:

Technique | Appropriate Size Range | Primary Advantage | Standard |

|---|---|---|---|

Laser Diffraction | 0.01 µm – 3,500 µm | Speed and broad dynamic range | ISO 13320 |

Dynamic Light Scattering (DLS) | 0.3 nm – 10 µm | High sensitivity for nanoparticles | ISO 22412 |

Automated Imaging | 0.5 µm – >10 mm | Shape analysis and agglomerate detection | ISO 13322 |

Sedimentation | 0.1 µm – 300 µm | High resolution for polydisperse samples | ISO 13317 |

Laboratory professionals must validate their chosen method against reference standards to ensure data integrity. Regular calibration verification using NIST-traceable microspheres helps confirm that the instrument is reading within acceptable tolerances.

How does sample preparation impact measurement accuracy?

Improper sample preparation is the leading cause of poor particle size consistency data and misleading analytical results. The sample extracted for analysis must be statistically representative of the bulk suspension, requiring strict adherence to the "Golden Rules of Sampling" (ensuring every particle has an equal probability of being selected). Failure to disperse the sample correctly can result in the measurement of agglomerates rather than primary particles, skewing the distribution curve toward larger sizes.

To achieve a stable dispersion state during analysis, laboratories often utilize surfactants or ultrasonic energy. Surfactants lower the surface tension, allowing the liquid medium to wet the particles thoroughly, while ultrasonication breaks the weak Van der Waals forces holding agglomerates together. However, excessive sonication can fracture fragile particles, creating a false population of fines that does not exist in the native product.

Best practices for suspension sampling:

- Agitation: Always mechanically stir the bulk container immediately before aliquoting to re-suspend settled material.

- Dilution: Use a filtered supernatant or the exact formulation vehicle for dilution to prevent thermal or chemical shock that could induce precipitation.

- Representative Volume: Analyze a sufficient sample mass to ensure that the presence of a few large particles does not statistically distort the result.

Standard operating procedures (SOPs) should define the specific energy input (Joules) for sonication and the precise concentration of dispersants. Verifiable documentation of these parameters is crucial for audit trails and method transfer between laboratories.

What is the role of zeta potential in maintaining suspension uniformity?

Zeta potential analysis provides a quantitative measure of the electrostatic repulsion between particles, serving as a predictor for long-term particle size consistency. A high zeta potential (typically greater than ±30 mV) indicates strong repulsive forces that prevent particles from approaching close enough to aggregate. When the zeta potential nears zero (the isoelectric point), attractive forces dominate, leading to rapid flocculation and an increase in effective particle size.

Measuring zeta potential allows formulators to optimize the pH and ionic strength of the suspension vehicle. By adjusting these chemical parameters, laboratory professionals can maximize the energy barrier between particles, thereby stabilizing the PSD. This is particularly vital for colloidal suspensions where surface chemistry plays a more dominant role than gravity.

Factors influencing zeta potential:

- pH Level: Most particles possess surface functional groups that protonate or deprotonate with pH changes, altering surface charge.

- Ionic Strength: High salt concentrations compress the electrical double layer, reducing the zeta potential and promoting aggregation.

- Additives: Adsorption of surfactants or polymers can sterically stabilize particles even when zeta potential is low.

Routine monitoring of zeta potential alongside particle size distribution provides a complete picture of suspension health. Peer-reviewed literature in the Journal of Colloid and Interface Science consistently highlights the correlation between zeta potential magnitude and shelf-life stability.

Conducting Zeta Potential Analysis

Zeta potential analysis is the fundamental method for predicting the long-term physical stability of colloidal suspensions by quantifying the magnitude of electrostatic charge repulsion between particles. Laboratory professionals use electrophoretic light scattering (ELS) to measure the velocity of particles in an applied electric field, which is then converted to zeta potential using the Henry equation. A zeta potential value outside the range of ±30 mV is generally accepted as the threshold for sufficient electrostatic stabilization to prevent flocculation and aggregation. If the zeta potential falls within the instability region (±10 mV to ±20 mV), the suspension is prone to rapid particle growth and sedimentation, requiring formulation adjustments such as pH modification or the addition of ionic surfactants. Consistent monitoring of this parameter ensures that the particle size consistency observed during initial manufacturing is maintained throughout the product's shelf life.

Conclusion: Achieving Reliable Particle Size Consistency

Ensuring particle size consistency in suspensions requires a multifaceted approach combining robust formulation strategies with validated analytical methods. By adhering to principles of sedimentation physics and utilizing advanced characterization tools like laser diffraction and DLS, laboratory professionals can predict and prevent stability failures. Regular monitoring of critical attributes such as zeta potential and strict control over sample preparation further safeguard the quality of the final product. Ultimately, maintaining a consistent particle size distribution is not merely a regulatory compliance task but a fundamental requirement for product efficacy and safety.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.