The field of food science is a dynamic intersection of chemistry, microbiology, and engineering, with the laboratory serving as its critical core. For laboratory professionals, understanding the intricate science of food processing is not merely academic; it is foundational to ensuring food safety, quality, and regulatory compliance. Each modification a food product undergoes—from a raw ingredient to a packaged good—introduces new variables that must be meticulously analyzed and controlled. A deep knowledge of food processing techniques enables accurate and efficient sample handling, method validation, and the precise interpretation of analytical results, directly impacting scientific outcomes and public health. The following exploration provides an authoritative overview of the scientific underpinnings of modern food processing, highlighting the analytical methodologies and innovative approaches central to contemporary laboratory workflows.

Foundational Techniques in Food Processing: A Scientific Perspective

At its heart, food processing is the application of scientific principles to convert raw ingredients into consumer-ready products. The primary objectives are to extend shelf life, enhance palatability, and ensure safety by controlling microbial growth and enzymatic activity. This requires a comprehensive understanding of how various physical and chemical treatments affect a food's matrix, a knowledge base crucial for the analytical laboratory.

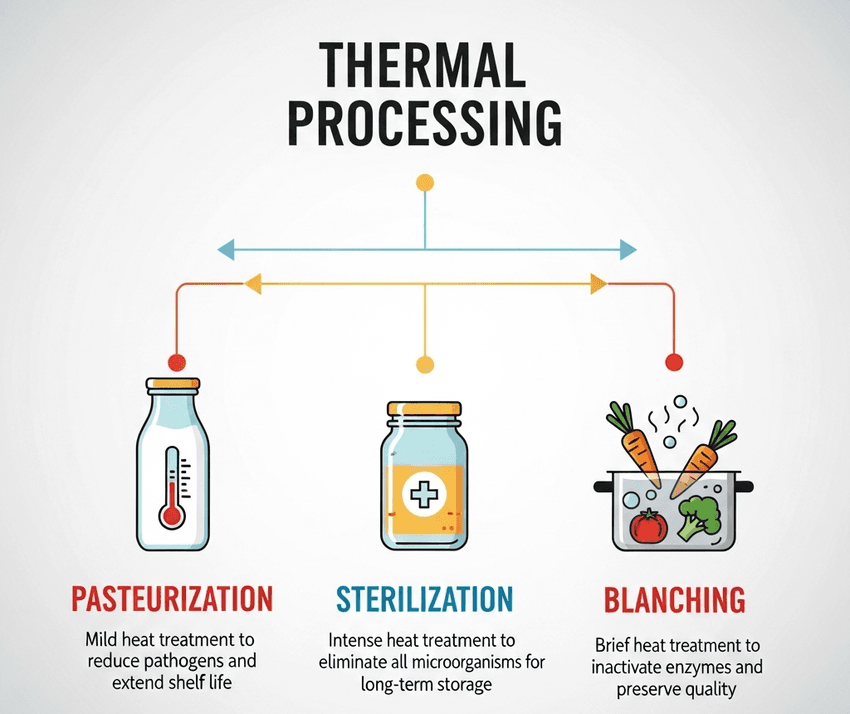

Thermal Processing

Thermal treatments are among the oldest and most widely used food processing methods. They rely on the principle of microbial inactivation through heat. The efficacy of these methods is quantified by D-values (decimal reduction time), which represent the time required to destroy 90% of a specific microbial population at a given temperature. Key thermal processes include:

Thermal processing of foods can involve a variety of techniques.

GEMINI (2025)

- Pasteurization: A moderate heat treatment (typically below 100°C) designed to kill specific pathogens, such as Listeria monocytogenes, Salmonella, and E. coli, in liquid foods like milk and juice, while minimizing changes to flavor and nutritional value. Laboratory analysis of pasteurized products often involves phosphatase activity tests to confirm the process was successful.

- Sterilization: A more severe heat treatment (above 100°C) applied to a product to destroy all microorganisms, including spores. This process, often conducted in retort chambers, results in a shelf-stable product. Post-sterilization analysis includes sterility testing and spoilage checks to ensure commercial sterility.

- Blanching: A brief, high-temperature treatment applied primarily to vegetables and fruits. While it does not achieve commercial sterility, it is essential for deactivating enzymes that cause spoilage and quality degradation, such as off-flavors and discoloration. The effectiveness of blanching can be verified in the laboratory by measuring peroxidase or catalase enzyme activity.

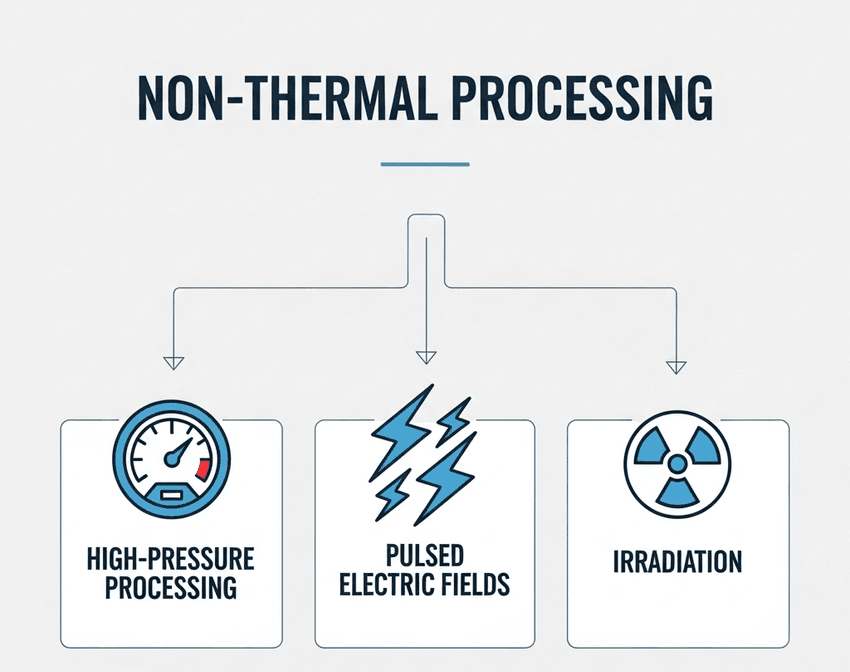

Non-Thermal Processing

Innovations in food processing have led to non-thermal methods that achieve microbial control without significant heat, preserving the sensory and nutritional attributes of the food.

High-pressure processing, pulsed electric fields, and irradiation are all examples of non-thermal processing.

GEMINI (2025)

- High-Pressure Processing (HPP): Also known as pascalization, this method uses extreme pressure (up to 87,000 psi) to inactivate vegetative bacteria, yeasts, and molds. It does not affect covalent bonds, preserving vitamins, flavor, and color. HPP is particularly useful for products like juices, deli meats, and ready-to-eat meals.

- Pulsed Electric Fields (PEF): This technique involves exposing food products to short, high-voltage pulses. The electric field creates pores in cell membranes, leading to microbial inactivation. PEF is a low-energy method with a minimal thermal footprint, making it ideal for liquid foods.

- Irradiation: The controlled use of ionizing radiation (gamma rays, X-rays, or electron beams) to destroy pathogens, insects, and parasites. This method extends shelf life and is highly effective for a range of products, including spices and poultry. Post-treatment analysis often involves detecting radiolytic by-products.

Analytical Methodologies for Quality Control in Food Processing

The laboratory is the final arbiter of product quality and safety, relying on a suite of sophisticated analytical techniques to validate every stage of food processing. The selection of a method is dictated by the analyte of interest and the sample matrix, requiring a deep understanding of instrumental limitations and sample preparation.

Chemical and Compositional Analysis

- Chromatography: Techniques such as Gas Chromatography-Mass Spectrometry (GC-MS) and Liquid Chromatography-Mass Spectrometry (LC-MS) are indispensable for separating and identifying volatile and non-volatile compounds. These instruments are used for flavor profiling, detecting pesticide residues, mycotoxins, and other contaminants.

- Spectroscopy:Near-Infrared (NIR) and Fourier-Transform Infrared (FTIR) spectroscopy offer rapid, non-destructive analysis of a product’s chemical composition. These methods are frequently used for the determination of moisture, fat, protein, and sugar content, providing real-time data for process control.

- Rheology: This discipline measures the flow and deformation of matter. In the context of food processing, rheological analysis provides insights into a product’s texture, viscosity, and consistency—critical quality attributes for consumers. Instruments like viscometers and texture analyzers are used to test a wide range of products, from sauces to baked goods.

Analytical Method | Principle of Operation | Common Application in Food Processing |

|---|---|---|

GC-MS | Separates compounds by volatility; identifies by mass-to-charge ratio. | Contaminant detection (pesticides, flavor compounds). |

LC-MS | Separates compounds by polarity; identifies by mass-to-charge ratio. | Mycotoxin and antibiotic residue analysis. |

NIR Spectroscopy | Measures absorption of light in the near-infrared spectrum. | Rapid compositional analysis (fat, protein, moisture). |

FTIR Spectroscopy | Measures absorption of infrared radiation. | Adulteration detection, quality control of oils. |

Texture Analysis | Measures force, time, and distance to simulate chewing. | Texture and mouthfeel determination (crispness, chewiness). |

The Critical Role of Microbiology in Ensuring Food Processing Safety

Microbiological analysis is paramount in a food processing environment. The primary goal is to prevent foodborne illness by controlling pathogens and minimizing spoilage organisms. This work requires meticulous attention to detail and adherence to standardized protocols.

Pathogen Detection

The laboratory's central responsibility is to detect and quantify foodborne pathogens, including Salmonella, pathogenic E. coli, Listeria monocytogenes, and Campylobacter. Traditional culture-based methods, while time-consuming, remain the gold standard. They involve enrichment steps to increase pathogen numbers, followed by selective plating on agars to isolate and identify the target organism.

However, the industry is increasingly moving towards rapid detection methods to accelerate product release and respond to potential contamination events more quickly. These methods include:

- Polymerase Chain Reaction (PCR): A molecular technique that amplifies and detects the DNA of specific pathogens. Quantitative PCR (qPCR) can even provide a measure of the pathogen load.

- Enzyme Immunoassay (EIA):Food analysis kits use antibodies to detect specific antigens on the surface of pathogens. These tests are fast and can be automated, making them suitable for high-throughput screening.

Hygienic Monitoring and Spoilage Indicators

In addition to direct pathogen testing, laboratory professionals monitor the effectiveness of sanitation and cleaning protocols. Environmental swabs and samples from food contact surfaces are routinely tested for indicator organisms like Total Plate Count (TPC), coliforms, and Enterobacteriaceae. The presence of these organisms suggests a breakdown in hygiene and can be a harbinger of potential pathogen contamination.

Spoilage organisms, such as yeasts and molds, are also tracked. While not always a direct health risk, their presence indicates potential shelf-life issues and can affect the organoleptic properties of the product. The data from these tests provides a scientific basis for quality control decisions and corrective actions.

Innovations and Automation: Shaping the Future of Food Processing Laboratories

The landscape of food processing is continuously evolving, driven by innovations in automation, data science, and analytical technology. Laboratories are at the forefront of this evolution, adapting their workflows to handle greater volumes of data and a wider range of analyses.

Advanced Sensors and Real-Time Monitoring

The integration of smart sensors into the food processing line allows for continuous, real-time monitoring of critical parameters. These sensors can measure temperature, pH, moisture content, and even microbial indicators. The data is transmitted directly to a central database, enabling a shift from reactive to proactive quality control. For the laboratory, this means a transition from routine spot-checking to validating and maintaining the integrity of these monitoring systems.

The Role of Data Science and AI

The sheer volume of data generated by modern analytical instruments and sensors necessitates advanced data analytics. Artificial intelligence (AI) and machine learning algorithms are being employed to:

- Predictive Quality Control: AI models can analyze historical process data to predict potential quality deviations or safety issues before they occur. For example, a model might identify a specific combination of temperature and humidity that increases the risk of mold growth in a stored ingredient.

- Rapid Contaminant Identification: Machine learning can rapidly analyze complex chromatographic or spectroscopic data to identify and quantify contaminants, reducing the time required for results.

- Supply Chain Traceability: Technologies like blockchain are being used to create an immutable record of a product's journey from farm to fork. Laboratories play a key role in providing the analytical data that populates this chain, ensuring transparency and accountability.

The future of food processing science will be defined by a seamless integration of these technologies with traditional laboratory expertise, allowing for more precise control and a higher standard of safety.

The Laboratory's Indispensable Role in Food Processing Science

The complex and multifaceted nature of modern food processing demands a rigorous, scientific approach, and the laboratory is the institution responsible for upholding this standard. From validating thermal processes to detecting trace contaminants and monitoring for microbial growth, laboratory professionals provide the data-driven insights necessary for both quality and safety. The ongoing evolution of food processing requires an equally dynamic response from the laboratory, embracing innovations in automation, data science, and analytical instrumentation. The synthesis of foundational knowledge with cutting-edge technology ensures that the food supply remains safe, nutritious, and of the highest quality, reaffirming the laboratory’s indispensable role in a globalized industry.

FAQ

What are the primary challenges in ensuring food safety through food processing?

Ensuring food safety is a multifaceted endeavor with several key challenges. A major concern is the survival of heat-resistant pathogens and spores during food processing, which necessitates meticulous process validation and microbial testing. Another challenge is the risk of post-process contamination from the environment, equipment, or personnel, which underscores the importance of stringent sanitation protocols. The complexity of modern supply chains also presents a challenge, as it requires robust traceability systems and consistent food safety standards across all stages of production. Continuous monitoring and a proactive approach are essential to mitigate these risks and protect public health.

How do laboratory professionals validate the effectiveness of a food processing method?

Validation of a food processing method is a rigorous, scientific process. It often begins with a food analysis of the raw ingredients to establish a baseline microbial load. A controlled "challenge study" can then be performed, where a known concentration of a target microorganism is added to the food product. The product is then subjected to the processing method, and post-process samples are analyzed to determine the microbial reduction. The goal is to achieve a specific log reduction (e.g., a 5-log reduction for pathogens) as mandated by regulatory bodies. The validation process ensures that the method consistently meets food safety and quality standards.

What is the significance of the Hazard Analysis and Critical Control Point (HACCP) system in food processing?

The Hazard Analysis and Critical Control Point (HACCP) system is a globally recognized, preventative approach to food safety. It systematically identifies potential hazards—biological, chemical, or physical—and establishes control measures at specific points in the food processing flow, known as Critical Control Points (CCPs). The laboratory is vital to HACCP, as it provides the scientific data required to monitor and verify these CCPs. For example, a lab might test the temperature of a pasteurization process or the pH of an acidified food to confirm that the CCP is being met, providing the data to demonstrate compliance and ensure product safety.

What emerging technologies are most impacting quality control and food processing?

Several emerging technologies are revolutionizing food processing and quality control. The use of advanced sensors and the Internet of Things (IoT) enables real-time data collection from the production line, providing immediate insights into process parameters. The integration of artificial intelligence (AI) and machine learning allows for predictive analytics, identifying potential issues before they compromise safety or quality. Furthermore, DNA-based technologies, such as next-generation sequencing, are providing a more comprehensive understanding of the microbial community within food, allowing for faster and more accurate pathogen detection and typing. These innovations are creating a more efficient and responsive food analysis ecosystem.