High-temperature safety in thermal analysis requires a systematic approach to hazard management to protect laboratory personnel and instrumentation from extreme heat and reactive byproducts. Laboratories must integrate strict engineering controls with standardized operational procedures to mitigate risks associated with differential scanning calorimetry (DSC), thermogravimetric analysis (TGA), and simultaneous thermal analysis (STA). The potential for rapid exothermic reactions, toxic gas evolution, and operational temperatures that can exceed 1000°C demands constant vigilance and adherence to established safety standards.

Identifying high-temperature hazards in thermal analysis instrumentation

Thermal analysis instrumentation presents unique safety challenges due to the combination of high operational temperatures, electrical power requirements, and the chemical nature of samples under test. Understanding these specific risks is the first step in establishing a comprehensive high-temperature safety plan.

Thermal and electrical risks: Furnaces used in TGA and DSC instruments frequently operate at temperatures ranging from ambient to 1600°C or higher. Accidental contact with external furnace surfaces, cooling flanges, or exposed heating elements can result in severe thermal burns. Electrical hazards also exist, as these instruments require high voltage to generate rapid heating rates. Regular inspection of power cords, furnace connections, and grounding systems is essential to prevent electrical shock or fire.

- Surface contact: External housing can retain heat long after an experiment concludes.

- Component failure: Aging heating elements may short-circuit, creating arc flash hazards.

- Cooling system failure: Inadequate cooling water flow can lead to overheating of the furnace shell.

Chemical and reaction hazards: Samples subjected to thermal analysis often undergo decomposition, phase transitions, or oxidation, which can release hazardous volatiles. High-temperature safety protocols must account for the unpredictable nature of unknown materials. Rapid decomposition can pressurize sample crucibles, leading to ruptures that damage the furnace and project hot debris.

- Evolved gases: Decomposition products may be toxic, corrosive, or flammable.

- Exothermic runaways: Certain materials release significant energy, exceeding the instrument's cooling capacity.

- Incompatible materials: Reactions between the sample and the crucible (e.g., aluminum pans with high-temperature metals) can cause containment failure.

Regulatory standards and compliance: Adhering to recognized standards ensures that hazard identification aligns with industry best practices. Organizations such as the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) provide guidelines relevant to thermal analysis laboratories.

- OSHA 1910.1450: Occupational exposure to hazardous chemicals in laboratories.

- NFPA 45: Standard on fire protection for laboratories using chemicals.

- ASTM E537: Standard test method for thermal stability of chemicals by differential scanning calorimetry.

Implementing engineering controls for thermal analysis safety

Engineering controls provide the most effective defense against high-temperature safety risks by physically isolating operators from hazards. Effective ventilation and instrument design features reduce exposure to heat and toxic emissions during thermal analysis.

Local exhaust ventilation (LEV): Proper ventilation is non-negotiable for instruments performing decomposition studies or evolved gas analysis. A dedicated local exhaust system or a snorkel hood positioned directly over the instrument exhaust port captures volatile byproducts at the source. This prevents the accumulation of hazardous fumes in the general laboratory environment.

- Direct connection: Connect instrument exhaust ports to a negative pressure system when possible.

- Flow rate verification: Regularly measure face velocity to ensure adequate capture efficiency (typically 80–100 fpm).

- Scrubbers: Use in-line chemical scrubbers for experiments known to produce acidic or corrosive gases.

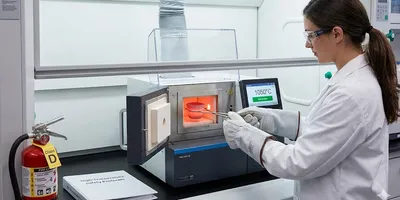

Instrument interlocks and shielding: Modern thermal analyzers incorporate safety interlocks designed to prevent operation under unsafe conditions. These automated systems stop furnace heating if cooling water flow is interrupted or if the furnace is not properly closed. Physical barriers and heat shields further protect operators from accidental contact with hot zones.

- Temperature limiters: Hardware-based over-temperature cutoffs prevent furnace meltdowns.

- Cooling monitoring: Flow sensors trigger automatic shutdown if coolant supply fails.

- Protective shields: Transparent polycarbonate or safety glass shields protect against crucible rupture debris.

Gas supply management: Thermal analysis relies on purge gases like nitrogen, argon, or air to control the sample atmosphere. High-temperature safety requires precise regulation of these gases to prevent over-pressurization or oxygen enrichment. Secure gas cylinders according to Compressed Gas Association (CGA) standards and use pressure relief valves on supply lines.

- Inert atmosphere: Essential for preventing uncontrolled oxidation of flammable samples.

- Oxygen sensors: Install monitoring devices in small labs to detect nitrogen leaks that could cause asphyxiation.

- Regulator maintenance: Inspect pressure regulators annually for drift or seal failure.

Establishing protocols for safe sample handling and crucible selection

Operational protocols dictate how laboratory professionals interact with samples and instruments to maintain high-temperature safety. Correct sample preparation and crucible selection prevent equipment damage and minimize the risk of violent reactions.

Crucible material compatibility: Selecting the appropriate crucible material is critical for preventing containment failure at elevated temperatures. Operators must verify that the crucible will not react with the sample or melt within the experimental temperature range. For example, while aluminum melts at 660°C, it is generally limited to 600°C in operation to prevent softening and deformation.

- Alumina (Ceramic): Stable to 1600°C+, chemically inert for most applications.

- Platinum: Excellent thermal conductivity but can form alloys with metals or react with organics.

- Aluminum: Limited to low-temperature DSC (<600°C); incompatible with higher temperature runs.

- High-pressure crucibles: Required for samples with high vapor pressure to prevent bursting.

Sample mass and loading: Limiting sample mass reduces the energy potential of exothermic reactions and minimizes the volume of evolved gases. Laboratories should establish maximum sample weight limits based on the instrument's sensitivity and the material's energetic potential. Overloading crucibles increases the risk of "volcanoing," where expanding material spills into the furnace, damaging sensors and heating elements.

- Small sample sizes: 5–20 mg is typically sufficient for accurate TGA/DSC data.

- Homogeneity: Uniform sample packing prevents localized hotspots.

- Lid configuration: Pierced lids allow gas escape; hermetically sealed lids require careful pressure monitoring.

Post-experiment cooling procedures: Safe retrieval of samples requires strict adherence to cooling protocols. Operators must never attempt to open a furnace or remove a sample until the system has returned to a safe temperature, typically below 50°C. Premature opening exposes the operator to radiant heat and can cause thermal shock that fractures ceramic furnace linings.

- Software indicators: Wait for the instrument software to signal "End of Test" and "Safe to Open."

- Force cooling: Utilize compressed air or liquid nitrogen cooling accessories to accelerate safe turnaround.

- PPE usage: Wear thermal-resistant gloves and safety glasses when handling recently used crucibles.

Mitigating thermal risks through maintenance and inspection

Routine maintenance ensures that safety mechanisms remain functional and that equipment degradation does not introduce new hazards. A preventive maintenance schedule helps identify wear in high-temperature components before failure occurs.

Furnace and sensor inspection: Regular visual inspection of the furnace interior reveals signs of contamination, cracking, or corrosion. Carbon deposits from organic decomposition can alter heat transfer and create electrical shorting risks. Thermocouples must be calibrated and checked for physical integrity to ensure accurate temperature reporting.

- Cleaning: Remove decomposition residues to prevent cross-contamination and unintended reactions.

- Calibration: Verify temperature accuracy using standard reference materials (e.g., Indium, Zinc).

- Seal integrity: Check vacuum seals and O-rings for embrittlement to prevent atmosphere leaks.

Cooling system verification: Liquid cooling systems, such as chillers or circulators, require regular fluid checks and filter cleaning. Blockages in the cooling circuit can lead to uncontrolled furnace heating and catastrophic instrument failure. Algae growth or mineral buildup in water lines reduces heat exchange efficiency.

- Fluid levels: Maintain coolant levels to prevent pump cavitation.

- Leak checks: Inspect hose connections for signs of weeping or brittleness.

- Interlock testing: Periodically simulate a cooling failure to verify the instrument shuts down as designed.

Emergency response protocols for thermal runaway events: Laboratory personnel must be trained in specific emergency response protocols for thermal runaway events, where a sample generates heat faster than it can be dissipated. If an instrument indicates a rapid, uncontrolled temperature spike, the immediate priority is to cease power delivery while maintaining ventilation to exhaust hazardous fumes. Operators should never open the furnace during a runaway event, as the influx of oxygen can trigger a flash fire or explosion. Emergency power-off (EPO) buttons should be accessible and clearly labeled. Protocols must also include the use of appropriate fire suppression agents; Class D extinguishers may be necessary if reactive metals are involved, whereas standard CO2 extinguishers are suitable for electrical fires surrounding the unit.

Achieving high-temperature safety in thermal analysis

High-temperature safety in thermal analysis relies on a cohesive strategy integrating hazard identification, robust engineering controls, and disciplined operational procedures. Laboratories that rigorously maintain ventilation systems, enforce crucible compatibility rules, and validate safety interlocks significantly reduce the risk of thermal injury and equipment damage. By prioritizing these evidence-based safety measures, professionals ensure the integrity of analytical data while maintaining a secure working environment.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.