Thermal analysis constitutes a fundamental suite of analytical techniques essential for characterizing how material properties evolve as a function of temperature or time. For laboratory professionals, mastering thermal analysis is critical. It ensures product quality, verifies regulatory compliance, and drives innovation across diverse sectors. These methodologies provide granular data regarding phase transitions, heat capacity, mass changes, and mechanical stiffness. Such data is indispensable for validating raw materials and finished products. By strictly controlling the temperature program and atmosphere, analysts can derive precise insights into the thermodynamic and kinetic behaviors of substances. This article examines the core principles of these techniques and their pivotal roles in sectors ranging from pharmaceutical development to advanced energy storage.

Fundamental thermal analysis techniques for material characterization

To understand the full scope of thermal analysis, one must first distinguish the primary methodologies utilized in modern laboratories. Each technique targets specific physical or chemical changes. Together, they provide a distinct piece of the material puzzle.

Differential scanning calorimetry (DSC)

DSC remains the workhorse of the thermal laboratory. It measures the difference in the amount of heat required to increase the temperature of a sample and a reference as a function of temperature. This technique is paramount for identifying phase transitions. These include melting points, crystallization temperatures, and glass transition temperatures (Tg). In polymer science and chemical manufacturing, DSC data allows for the determination of purity and heat capacity. The precise quantification of endothermic and exothermic events enables researchers to map out phase diagrams. It also helps them understand thermal history, which directly influences processing conditions.

Thermogravimetric analysis (TGA)

While DSC focuses on heat flow, TGA measures mass change. A high-precision balance records the weight of a sample as it is heated, cooled, or held at a constant temperature. TGA is the gold standard for determining thermal stability and composition. It effectively quantifies moisture content, volatile components, and filler percentages in composites. Furthermore, TGA kinetics are frequently employed to estimate the lifetime of materials by analyzing decomposition profiles under varying heating rates. However, accurate predictions require strict adherence to assumptions such as Arrhenius behavior and single-step kinetics. Analysts often refer to standards like ASTM E698 to validate these kinetic models.

Dynamic mechanical analysis (DMA)

DMA characterizes the mechanical properties of materials as they are subjected to a periodic stress. This technique yields data on the storage modulus (elastic response) and loss modulus (viscous response). It is particularly sensitive to the glass transition and secondary relaxations in polymers. It often detects transitions that are too subtle for DSC. DMA provides crucial insight into how a material will physically perform under mechanical load across a temperature range.

Technique | Primary Measurement | Key Properties Determined |

|---|---|---|

DSC | Heat Flow | Melting point, Tg, Crystallinity, Purity, Reaction Kinetics |

TGA | Mass Change | Thermal Stability, Decomposition, Moisture/Volatile Content |

DMA | Mechanical Stiffness | Viscoelasticity, Modulus, Damping, Softening Points |

Optimizing drug development and shelf-life prediction in pharma

The pharmaceutical industry relies heavily on thermal analysis to ensure the efficacy and safety of drug products. In this highly regulated environment, the physical state of an active pharmaceutical ingredient (API) dictates its bioavailability and processability.

Polymorphism and amorphous content

APIs can exist in multiple crystalline forms (polymorphs). Each form has different thermodynamic stability and solubility profiles. DSC and TGA are routinely used to screen for polymorphism. An unstable polymorph may revert to a stable form during storage. This reversion can potentially alter the dissolution rate and therapeutic effect. Furthermore, amorphous solid dispersions, often created to enhance solubility, are thermodynamically unstable. Thermal analysis monitors the glass transition temperature to predict physical aging and recrystallization risks.

Drug degradation and stability

Understanding drug degradation pathways is essential for formulation design. TGA provides immediate data on the temperature at which an API begins to decompose. However, isothermal calorimetry and microcalorimetry offer deeper insights into slow degradation processes at ambient temperatures. By applying Arrhenius kinetics to thermal data, scientists can model reaction rates and activation energies. This modeling is central to shelf-life prediction. It allows laboratories to extrapolate accelerated stability data to real-time storage conditions with high confidence.

High-throughput automated screening

Modern drug discovery generates thousands of candidates that require rapid physical characterization. Automated screening using robotic thermal analyzers has revolutionized this workflow. These systems can run dozens of samples sequentially. They employ fast-scan DSC or TGA to quickly identify candidates with optimal thermal profiles. This high-throughput approach reduces the time-to-market by filtering out thermally unstable compounds early in the development pipeline. Throughout this process, professionals frequently refer to USP <891> Thermal Analysis for detailed guidelines, while adhering to USP <1058> Analytical Instrument Qualification for the validation and qualification of the instruments used.

Material innovation in battery R&D and agricultural polymers

Beyond pharmaceuticals, thermal analysis is a cornerstone of innovation in material science, particularly within the energy and agricultural sectors.

Enhancing battery R&D and performance

The rapid expansion of electric vehicles and portable electronics has placed battery R&D at the forefront of laboratory science. Thermal management is the critical safety barrier for Lithium-ion batteries. Thermal analysis techniques, specifically Accelerated Rate Calorimetry (ARC) alongside DSC, are used to study the thermal stability of cathodes, anodes, and electrolytes.

Determining the onset temperature of exothermic decomposition reactions helps engineers predict the risk of thermal runaway. Furthermore, DSC is utilized to inspect the melting integrity of polymer separators—the porous membranes between the anode and cathode. If a separator melts or shrinks prematurely, it causes a short circuit. TGA is also employed to analyze the composition of electrode slurries and verify the carbon content. This ensures the electrochemical performance meets design specifications.

Agricultural polymers and biodegradability

In the agricultural sector, the shift toward sustainable practices has driven the development of biodegradable agricultural polymers. These are used for applications like mulch films and controlled-release fertilizer coatings. Laboratory professionals use thermal analysis to balance durability with degradability.

TGA is particularly useful here for simulating environmental weathering. By coupling TGA with evolved gas analysis (EGA), researchers can identify the gaseous byproducts of decomposition to ensure they are non-toxic. Furthermore, verifying the melting point and crystallinity via DSC ensures that these polymers maintain their structural integrity under high heat conditions. This confirms they can withstand agricultural environments yet still break down efficiently in composting facilities.

Enhancing safety protocols, waste management, and forensic investigations

The utility of thermal analysis extends into safety compliance, ecological sustainability, and legal investigations. It acts as a critical tool for risk assessment and identification.

Safety and hazard assessment

Laboratory safety protocols rely on accurate data regarding material stability and energy release potential. While dedicated testers measure flash points, Differential Scanning Calorimetry (DSC) acts as a preliminary screening tool for energetic instability. It identifies potential hazards early by quantifying the enthalpy of decomposition. However, DSC is not a definitive test. Hazard classification often requires confirmatory testing using Accelerated Rate Calorimetry (ARC) or UN gap tests. This tiered approach prevents industrial accidents by identifying thermal hazards before materials enter large-scale production.

Waste management and pyrolysis

Effective waste management strategies increasingly utilize thermal conversion technologies like pyrolysis and gasification. Thermal analysis simulates these processes on a micro-scale. TGA allows researchers to optimize the temperature ramps required to maximize the recovery of valuable hydrocarbons from plastic waste or biomass. Understanding the decomposition kinetics of complex waste streams enables the design of efficient reactors. These reactors minimize residue and maximize energy recovery, supporting the circular economy.

Forensic investigations

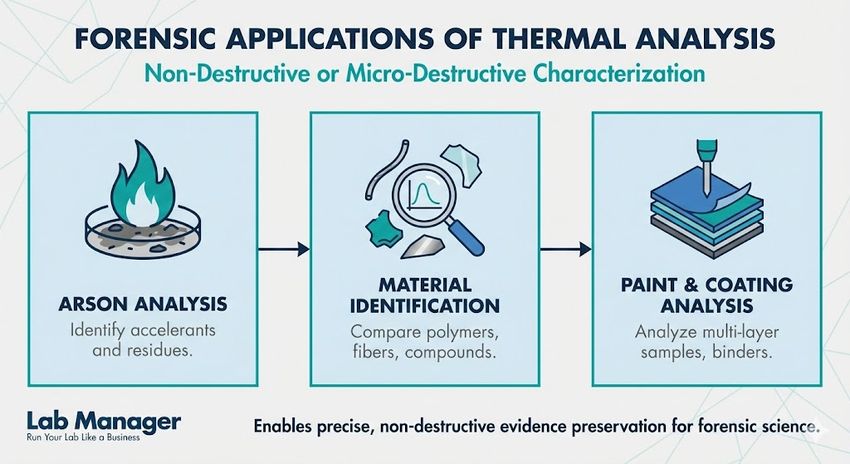

In forensic investigations, minute trace evidence often holds the key to solving cases. Thermal analysis provides a non-destructive or micro-destructive means to characterize these materials.

This infographic illustrates the key non-destructive and micro-destructive forensic applications of thermal analysis.

GEMINI (2026)

- Arson Analysis: TGA and DSC can characterize fire debris. This helps to distinguish between polymers found at a scene and accelerants.

- Material Identification: When unidentified plastic fragments or fibers are found, their melting points and glass transition temperatures serve as a "thermal fingerprint." Comparing these thermal signatures against a library of known standards allows forensic scientists to identify the manufacturer or batch of a material. This provides crucial links in criminal investigations.

- Paint and Coating Analysis: Automotive paint chips can be analyzed via TMA (Thermomechanical Analysis) or DSC. This determines their curing history and layer composition, aiding in hit-and-run investigations. To ensure such forensic and safety data stand up to legal and scientific scrutiny, organizations such as the American Society for Testing and Materials (ASTM) provide rigorous standards, including ASTM E1131 for Thermogravimetry.

The future of thermal analysis in laboratory science

As material complexity increases, the role of thermal analysis in the laboratory continues to expand. From ensuring the stability of life-saving medications through precise shelf-life prediction to enabling the safe design of high-energy batteries in battery R&D, these techniques are foundational to modern science. The integration of automated screening and advanced kinetic software allows laboratory professionals to generate higher-quality data with greater efficiency. This minimizes error and maximizes throughput.

Whether characterizing novel agricultural polymers or conducting critical forensic investigations, the ability to accurately measure material properties as a function of temperature remains a definitive skill set. By adhering to rigorous standards and leveraging the full spectrum of thermal techniques, laboratories can ensure safety, compliance, and continued innovation in an evolving scientific landscape.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.