Inline rheology monitoring enables laboratory professionals and process engineers to measure material flow properties directly within the manufacturing stream without extracting samples. This real-time analysis is critical for maintaining product quality, as inline rheology monitoring detects process deviations immediately, allowing for instant corrective actions. By eliminating the time delay associated with offline testing, manufacturers significantly reduce scrap rates and energy consumption while ensuring adherence to strict specifications.

How inline rheology monitoring systems function

Inline rheology monitoring involves the installation of rheological sensors directly into pipes, tanks, or extruders to measure viscosity and, in advanced systems, viscoelastic properties under process conditions. Unlike offline methods that require sample conditioning and transport to a quality control lab, inline systems provide continuous data streams reflecting the material's state at actual process temperatures and shear rates. This immediacy ensures that the rheological data correlates directly with process variables such as pressure, temperature, and flow rate.

The fundamental operation relies on measuring the resistance of a fluid to flow or deformation in real time. Different sensor geometries function based on specific flow characteristics, often utilizing pressure drop measurements across a known geometry, drag force on a stationary element, or vibrational responses to shear forces. These systems are designed to withstand harsh industrial environments, including high pressures and aggressive chemical compositions, ensuring durability alongside precision.

Understanding the distinction between Newtonian and non-Newtonian behavior is essential for interpreting data from inline rheology monitoring systems. Most industrial fluids, such as polymer melts, slurries, and emulsions, exhibit complex non-Newtonian behaviors where viscosity changes with shear rate. Inline sensors must characterize these fluids accurately to predict how they will behave during dispensing, coating, or molding operations.

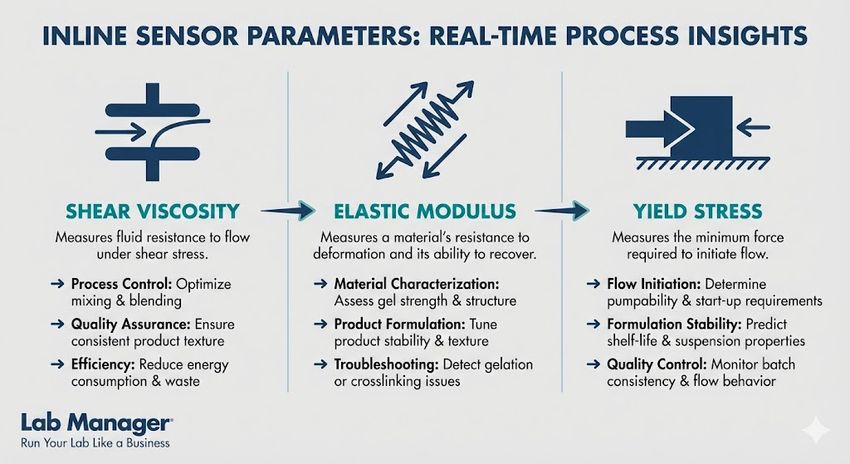

By monitoring these three key parameters—Shear Viscosity, Elastic Modulus, and Yield Stress—you can optimize product consistency, reduce waste, and accelerate batch release times.

GEMINI (2026)

Key parameters measured include:

- Shear Viscosity: The resistance to flow under shear stress; the most common inline measurement.

- Elastic Modulus: The tendency of the material to recover its shape after deformation (requires oscillatory or advanced squeeze-flow sensors).

- Yield Stress: The minimum stress required to initiate flow, critical for pastes and gels.

Selecting sensor technologies for real-time viscosity analysis

Selecting the appropriate sensor technology for inline rheology monitoring depends heavily on the material properties and the specific manufacturing environment. Different sensor types utilize distinct physical principles to capture rheological data, varying in their ability to measure shear-dependent behavior.

Capillary and Slit Die Rheometers: These instruments function by diverting a small side stream of the melt or fluid through a channel with precise dimensions (die). By measuring the pressure drop across the channel at a controlled volumetric flow rate, the system calculates shear stress and shear rate to determine viscosity.

- Application: Widely used in polymer extrusion and fiber spinning.

- Advantage: Provides data at defined, variable shear rates, making the data directly comparable to laboratory capillary rheometers.

- Limitation: Requires a side stream (bypass) and gear pump, which increases complexity and residence time.

Vibrational and Torsional Sensors: Vibrational viscometers operate by immersing a vibrating element (rod, tuning fork, or sphere) into the fluid and measuring the damping of the vibration caused by the fluid's viscosity (often viscosity × density). Torsional sensors use a similar principle but rely on rotational oscillation.

- Application: Common in coating lines, paints, inks, and lower viscosity chemical processing.

- Advantage: Compact design with no moving mechanical parts facilitates easy cleaning (CIP) and installation directly in tanks or pipes.

- Limitation: typically operates at a single high frequency/shear rate, which may not fully characterize highly shear-thinning fluids without correlation models.

Oscillating Piston and Squeeze Flow: These systems utilize a piston that moves within a measurement chamber, drawing fluid in and forcing it out. The time required for the piston's motion is correlated to viscosity. Advanced squeeze flow techniques compress material between plates to determine viscoelastic properties.

- Application: Fuel oils, ceramic pastes, food doughs, and filled polymer composites.

- Advantage: Extremely robust against abrasive materials and capable of handling small sample volumes in the measurement zone.

Why inline rheology monitoring improves quality control

Inline rheology monitoring transforms quality control from a reactive post-production verification to a proactive process control strategy. By integrating rheological data directly into the process control loop, manufacturers achieve tighter tolerances and higher overall equipment effectiveness (OEE).

Closed-Loop Process Control: The primary benefit of inline rheology monitoring is the ability to establish closed-loop feedback systems. If the viscosity drifts outside of specification due to raw material variation or temperature fluctuation, the control system can automatically adjust process parameters—such as screw speed, temperature profile, or dosing pump rates—to compensate. This capability stabilizes the process without operator intervention.

Waste Reduction and Sustainability: Traditional quality control often identifies out-of-spec material only after a batch is complete or a significant length of product has been extruded. Real-time monitoring detects issues immediately, drastically reducing the volume of off-spec material produced. This reduction in scrap contributes directly to sustainability goals by minimizing raw material usage and the energy required for reprocessing or disposal.

Traceability and Compliance: Industries such as pharmaceuticals and medical device manufacturing require rigorous documentation of process conditions. Inline rheology monitoring provides a continuous digital record of material properties throughout the production run. This data is essential for validating that the manufacturing process remained within the validated design space, satisfying regulatory requirements from agencies like the FDA or EMA.

Operational Benefit | Mechanism | Outcome |

|---|---|---|

Reduced Scrap | Instant detection of viscosity drift | Minimized off-spec production |

Energy Efficiency | Optimized extruder/pump load | Lower power consumption |

Faster Changeovers | Real-time verification of new batch | Reduced transition time |

Enhanced Safety | Monitoring of polymerization exotherms | Prevention of runaway reactions |

Integrating inline rheology with Process Analytical Technology (PAT)

The adoption of inline rheology monitoring is a critical component of Process Analytical Technology (PAT) frameworks in the pharmaceutical and chemical industries. PAT is defined by the FDA as a mechanism to design, analyze, and control manufacturing through timely measurements of critical quality and performance attributes. Inline rheology serves as a direct measurement of a critical quality attribute (CQA)—viscosity or viscoelasticity—linking it to critical process parameters (CPP). By implementing inline rheology monitoring within a PAT strategy, manufacturers move away from fixed process conditions toward a dynamic control strategy based on material response. This shift ensures that the final product quality is consistent, even if raw material lots vary slightly, as the process adapts in real time based on the rheological feedback.

Key applications in polymer and chemical manufacturing

Inline rheology monitoring is indispensable in polymer processing, where molecular weight distribution and branching directly influence processability and final part performance. During processes such as reactive extrusion or polymerization, the viscosity of the melt evolves rapidly as the chemical reaction progresses.

Polymerization Monitoring: In the production of polymers, viscosity is often a direct indicator of molecular weight. Inline sensors track the polymerization reaction in real time, allowing operators to determine exactly when the desired chain length has been achieved. This precise endpoint detection prevents over-processing, which can degrade the polymer, or under-processing, which leads to poor mechanical properties.

Recycled Material Consistency: The increasing use of recycled plastics introduces significant variability in feedstock viscosity. Recycled streams often contain mixtures of different grades or varying levels of degradation. Inline rheology monitoring allows the processing equipment to adapt to these fluctuations dynamically. For example, if a batch of recycled polyethylene has a lower viscosity than expected, the system might automatically lower the processing temperature to restore melt strength.

Food and Beverage Processing: In food manufacturing, texture and mouthfeel are critical consumer attributes directly linked to rheology. Inline monitoring ensures consistent texture in products like yogurt, sauces, and chocolate.

- Chocolate: Viscosity and yield stress determine how well chocolate coats a wafer or fills a mold.

- Batters and Doughs: Consistency measurements ensure uniform baking and expansion.

Research published in the Journal of Food Engineering (Tabilo-Munizaga & Barbosa-Cánovas, 2005) highlights that real-time viscosity regulation significantly improves texture uniformity in large-scale dairy processing. Similarly, industry guidelines from the Society of Plastics Engineers note that inline monitoring is a requisite for high-speed precision extrusion of medical tubing, where dimensional stability is governed by melt consistency.

Achieving manufacturing excellence with inline rheology monitoring

Inline rheology monitoring represents a fundamental shift in manufacturing process control, moving operations from reactive testing to proactive, data-driven management. By providing continuous, real-time visibility into material properties, these systems enable manufacturers to optimize production speed, reduce waste, and ensure compliance with rigorous quality standards. The integration of inline rheology monitoring into SCADA and PAT frameworks allows for automated, closed-loop control that adapts to raw material variability and processing fluctuations. As industries continue to prioritize digitalization and sustainability, the role of inline rheological data will remain central to achieving operational excellence and product consistency.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.