Lab presses let engineers create and test numerous material samples in a controlled environment. While traditional presses rely on manual operation, time‑pressed labs seeking faster, higher‑quality output are shifting to automated models.

Automated presses used to prepare pellets, plaques, briquettes, and cakes offer a variety of advantages over their manual predecessors, including:

- Set-and-forget operation

- Repeatable sample creation

- Storage of dozens of recipes

How they work: Manual vs. automated lab presses

Manual presses have been used to create samples with plastic materials for more than 100 years. While the physics remains the same whether you use a manual or an automated press, of course, the physical nature of the former is a key difference—but not the only one.

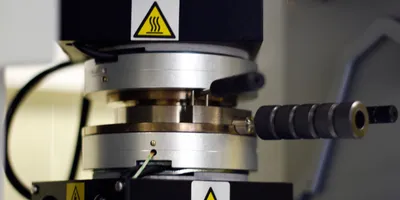

Both presses start with a mold top and mold bottom with a “picture frame” in the middle. Plastic material, typically pellets, is loaded into the frame, which is put onto the press.

A manual press has a bottle jack with a lever that the operator must manually actuate up and down for several strokes to close the clamp. Pressure begins to build once it makes contact, and the operator must watch a pressure gauge to set the correct pressure for the application.

As the material starts to melt, pressure bleeds off naturally. Throughout the process, the operator must stand at the press and remain keenly aware until the sample is complete.

This is ideal for someone creating one or two samples per day or week. But if your volume is higher, or your staff is handling a heavy workload, an automated press becomes the ideal choice.

An automated press lets you program the required pressure, temperature, and dwell time. These parameters can be saved in up to 250 custom recipes and called up when needed. Each recipe can specify up to 25 parameters, and the press will automatically advance through all those programmed parameters, then open automatically once the timer expires. That leaves the operator free to complete other tasks while the press maintains the required force and temperature. And, because the operator isn’t manually closing the press multiple times a day, physical fatigue is reduced.

Quality control is elevated substantially with an automated press, as each sample is produced under the exact conditions time after time.

Eliminating human error

In addition to the aforementioned benefits of automated presses are a range of functions that exponentially increase repeatable, reliable outcomes:

Digital monitoring: Graphing capabilities show operators exact time and pressure vs. monitoring pressures on a gauge, as with a manual press.

Pressure maintenance: There is no need to observe a pressure gauge on an auto press. Clamping force can be programmed in 100-pound increments, and the press will automatically maintain pressure within plus or minus 200 pounds of the setpoint.

Programmable dwell time: Curing dwell time is critical in most applications. Contemporary presses let users program the dwell timers, and the clamp will open automatically once the time expires.

Data protection: Customizable cycles, or “recipes,” are password protected to prevent accidental alterations and ensure reliable, repeatable results with every use.

How to choose an automated press

Deciding on what automated press to choose for your lab depends on the materials, applications, and volume you require. Primary options include:

Unheated, heated, or heated and cooled: Some applications don't require heat; for example, compressing powders and compressing into a disk, which is simply a force-only application. But molding plastic or rubber samples requires heated platens.

Clamp pressure required: Automated presses can achieve varying intervals of clamp pressure depending on the PSI each application requires.

Sample sizes: Platen sizes can easily be matched to typical sample sizes—ranging from 6 inches by 6 inches to 18 inches by 18 inches—and even larger for presses that can also produce final parts as well as samples.

Custom features: Some vendors can add special capabilities, such as the ability to heat or cool at specific rates, or mount tooling or molds into a clamp. Users creating samples to test for and maintain ASTM or ISO standards might require further specifications. Other custom options include:

- Special programming features that let users control temperature ramping rates and display mold temperatures.

- Custom mechanical options such as carrier consoles and worktables aligned with the clamp, mold/tooling fixture methods, and split frame designs that let users separate the operating controls from the pressing clamp.

- Upgraded safety features that are UL/CSA compliant, CE certified, or meet special OHSA and ANSI requirements.

Hybrid solution: Some manual presses can be automated with an add-on power unit and controls package that allows storage of recipes and clamp force settings.