High-volume biological studies necessitate impeccable quality control across all lab operations. The integrity and reliability of research and diagnostic results fundamentally depend on the quality of the initial material used for analysis. Ensuring proper sample management is a primary challenge in modern analytical environments. Throughput demands are often high, and samples must remain viable for years. Professionals must prioritize rigorous, auditable methods. These methods safeguard materials from collection through processing, storage, and eventual analysis. A failure at any point in the sample lifecycle compromises the study's scientific validity. This failure includes mishandling, temperature excursion, or mislabeling. Errors drive up costs, waste valuable biological material, and invalidate months of intricate work. Establishing and maintaining a secure, efficient system for sample handling enhances data reliability and operational efficiency. This process protects the valuable biological resource across the laboratory.

The critical role of standardized processes in sample management

Standard operating procedures (SOPs) define the foundation for reliable data generation in biological studies. The pre-analytical phase often requires the most rigorous attention. This is where the majority of errors originate. Sample management protocols must detail every step. This ranges from patient preparation to the moment the specimen enters the analytical platform. Laboratory personnel should strictly adhere to established standards. These standards cover venipuncture technique, collection device compatibility, and immediate processing requirements.

Variability introduced during specimen handling directly impacts downstream analytical results. Examples include improper centrifugation speed, incorrect time-to-freezing, or inappropriate anticoagulant use. For instance, delaying the separation of plasma from whole blood can alter metabolite profiles. Minimizing this variability requires several foundational elements:

- Detailed documentation covering all procedural steps.

- Regular competency assessments for all personnel.

- Ongoing training programs focused on standardized techniques.

The Clinical and Laboratory Standards Institute (CLSI) provides extensive guidelines on specimen collection and processing. These guidelines offer a crucial framework for developing internal SOPs (Reference: Clinical and Laboratory Standards Institute. Collection, Transport, Preparation, and Storage of Specimens for Molecular Methods; Approved Guideline.). Furthermore, regulatory bodies like the FDA emphasize the necessity of documented, controlled processes for materials used in clinical biological studies. This specifically relates to the preparation of test articles (Reference: U.S. Food and Drug Administration. Good Laboratory Practice for Nonclinical Laboratory Studies.). Implementing these standard protocols ensures every specimen arrives at the analysis stage supporting maximum scientific fidelity. This focus on upfront control saves significant resources in later lab operations and minimizes the need for costly recollection.

Optimizing biological studies through cryogenic storage and inventory

Maintaining sample integrity over extended periods remains crucial for longitudinal biological studies. Effective sample management hinges on the appropriate selection and maintenance of storage conditions. Temperature-sensitive materials require strict environments. These materials include nucleic acids, proteins, and viable cells. Ultra-low temperature conditions are essential.

Proper container selection prevents sample loss or degradation. Laboratories should prioritize cryogenic vials with secure, chemically inert seals. This approach guards against thermal stress or cap failure during freeze-thaw cycles. Inventory control systems must accurately reflect the physical location of every tube. This includes tubes within a freezer, tank, or automated storage unit. High-volume environments benefit from automated storage solutions. Automation reduces human exposure and minimizes temperature fluctuations from door openings. It also accelerates retrieval times.

The International Society for Biological and Environmental Repositories (ISBER) sets global best practices for biorepository management. This focus includes temperature monitoring, contingency planning, and security (Reference: International Society for Biological and Environmental Repositories. Best Practices for Repositories.). Continuous temperature monitoring, complete with auditable alarm logs, ensures materials remain viable for future analysis. A robust contingency plan for equipment failure also supports subsequent phases of biological studies.

Implementing robust tracking systems for efficient lab operations

Comprehensive tracking establishes the chain of custody. It provides an unbroken, immutable record for every specimen used in biological studies. Effective sample management systems rely heavily on automated identification technologies. Primary technologies are high-density 2D barcodes etched onto the base of cryovials and microplates. These barcodes ensure rapid and error-free registration. Scanning a barcode upon receipt, movement, retrieval, and disposition automatically updates the specimen's comprehensive metadata. This eliminates potential manual transcription errors and ensures data fidelity.

A specialized Laboratory Information Management System (LIMS) should serve as the central repository for all sample-related data. This includes detailed information. Examples are the original collection time, initial volume, detailed processing steps (e.g., aliquots, homogenization protocols), storage location, and associated quality control metrics. The system must enforce strict access controls. It must also maintain an immutable audit trail detailing every interaction with the specimen. This is paramount for meeting rigorous regulatory compliance standards. Efficient lab operations depend on the LIMS's ability to rapidly query and locate specific samples based on complex criteria. For instance, filtering all plasma samples from a specific patient cohort processed on a given date minimizes retrieval time. It also prevents errors in accessioning materials for downstream processing. Implementing robust electronic tracking systems transforms sample management. It moves from static, paper logs to a dynamic, queryable resource. This transformation underpins data provenance and research integrity across the entire laboratory workflow.

Integrating laboratory automation with LIMS infrastructure revolutionizes high-throughput sample management. It creates a closed-loop system. Automated robotic systems execute repetitive tasks with far greater precision and speed than manual methods. These tasks include aliquoting, capping/decapping, and plate stamping. Crucially, connecting these robotic platforms directly to the LIMS ensures physical sample movement and volume transfers. Process completions are instantly and accurately recorded in the digital database. This real-time, bi-directional synchronization minimizes the risk of location discrepancies. These discrepancies commonly arise from delayed or manual inventory updates. Furthermore, the LIMS can intelligently schedule tasks for the automation platforms. This optimizes workflows and maximizes instrument utilization while reducing reagent waste. Such integration is particularly critical for large-scale biological studies involving thousands of biospecimens. Small processing delays or transcription errors, when compounded, threaten the validity of the final analysis. The result is a highly scalable, secure, and error-resistant system. This system is essential for modern lab operations focused on achieving high throughput without compromising data quality.

The quality assurance loop: Monitoring and contingency planning in sample management

A comprehensive quality assurance (QA) framework is integral to reliable sample management and continuous improvement in lab operations. This framework incorporates continuous monitoring and verification throughout the specimen lifecycle. It goes beyond initial processing standards. The quality system must track and record critical quality metrics before analysis proceeds. Failure to monitor these factors leads to misinterpretation of results in biological studies.

Key Quality Metrics for Biological Studies:

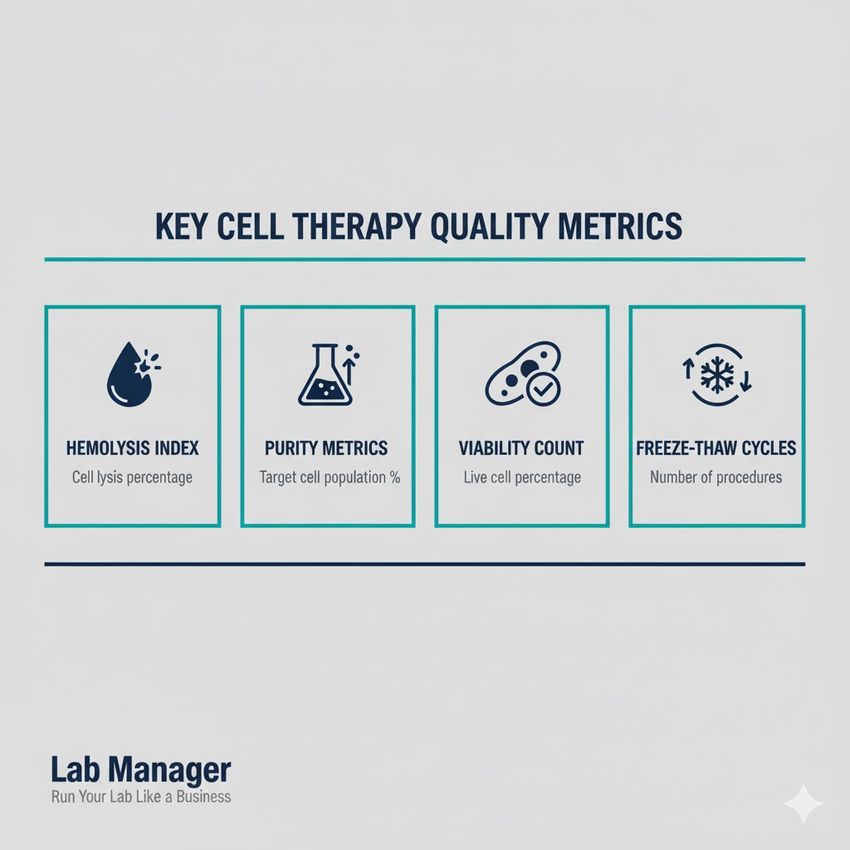

Essential Cell Therapy Quality Metrics for laboratory control and product consistency.

GEMINI (2025)

- Hemolysis index: Quantitative measurement of red blood cell rupture in blood-derived samples, which can release intracellular components that interfere with assays.

- Purity metrics: For nucleic acids, the A260/A280 and A260/A230 ratios indicate protein and organic contamination, respectively, essential indicators for accurate quantification.

- Viability count: Crucial for cell lines and primary cell cultures before cryopreservation, predicting post-thaw recovery.

- Freeze-thaw cycles: The number of recorded temperature excursions for a specific specimen, as this directly correlates with biomolecule degradation.

Contingency planning is equally vital for maintaining the integrity of stored materials. High-volume repositories require redundancy for all critical infrastructure components. This includes backup power supplies (uninterruptible power supplies, or UPS) capable of sustaining ultra-low-temperature freezers during an outage. It also requires redundant temperature monitoring probes and access to secondary storage units. This allows for rapid transfer during major equipment failures. Regular system audits, including mock failure drills, test the readiness of both personnel and technology. These tests ensure the ability to handle emergency scenarios. Adhering to these rigorous QA standards ensures that the investment made in meticulous sample management protects the scientific validity of long-term biological studies. The World Health Organization (WHO) emphasizes rigorous quality control processes in all aspects of biomedical research to ensure data reliability (Reference: World Health Organization. Handbook for Good Clinical Laboratory Practice (GCLP).).

Conclusion: Secure sample management drives reproducible research

Effective sample management is not merely a logistical challenge. It represents a core scientific and operational requirement for high-volume biological studies. Establishing rigorously documented protocols for the pre-analytical phase is essential. Investing in reliable cryogenic storage and implementing sophisticated LIMS-based tracking systems collectively safeguards specimen integrity. By prioritizing standardization and technological integration, laboratories minimize error rates. They also ensure robust data provenance and uphold the scientific rigor necessary for successful research and diagnostic outputs. The continued focus on optimizing sample management procedures will ultimately translate into more reliable, reproducible, and impactful results across all lab operations.

Frequently asked questions

How does pre-analytical variability affect downstream analysis?

Pre-analytical variability accounts for a significant majority of laboratory errors. Improper handling, such as delayed processing or incorrect temperatures, can degrade biological components. This can include enzyme activity or protein phosphorylation states. It may also cause cellular rupture, releasing interfering substances. This leads to inaccurate or non-reproducible analytical results.

What are the regulatory requirements for the storage of biospecimens in biological studies?

Regulatory requirements often dictate adherence to Good Laboratory Practice (GLP) or Good Clinical Practice (GCP) principles. These typically mandate documented, controlled conditions, continuous temperature monitoring, and robust audit trails. They also require specific procedures for equipment qualification and maintenance to ensure the integrity of the sample management process.

How do 2D barcodes improve efficiency in lab operations?

Two-dimensional (2D) barcodes store substantially more data than linear barcodes. They also allow for non-orientation-specific reading. This enables faster, automated scanning using high-throughput readers. This minimizes the time required for accessioning and inventory updates, virtually eliminating transcription errors inherent in manual tracking.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.