Thermal analysis is a foundational methodology for laboratory professionals characterizing the physical properties, stability, and degradation mechanisms of agricultural polymers. Using techniques like Differential Scanning Calorimetry (DSC) and Thermogravimetric Analysis (TGA), researchers can predict how mulch films, controlled-release fertilizer coatings, and hydrogels behave in the field. This precision is essential for verifying compliance with biodegradability standards. It ensures polymers perform reliably throughout their service life before decomposing.

Characterizing thermal transitions in biodegradable mulch films using DSC

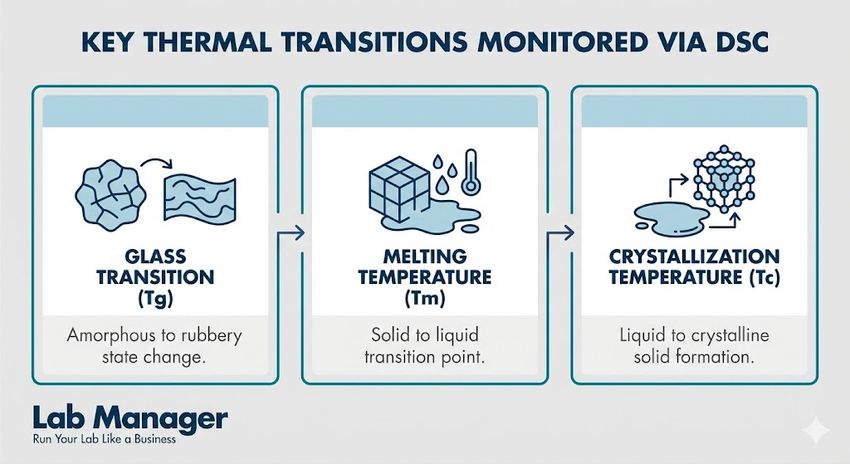

Differential Scanning Calorimetry (DSC) quantifies the heat flow associated with phase transitions to predict the flexibility and brittleness of agricultural films under field conditions. Laboratory professionals rely on DSC to determine the glass transition temperature (Tg) and melting temperature (Tm) of biopolymers such as polylactic acid (PLA) and polybutylene adipate terephthalate (PBAT). These thermal events directly correlate with the mechanical performance of the film during the growing season.

Understanding the degree of crystallinity is vital for predicting the degradation rate of mulch films. For many aliphatic biodegradable polyesters, higher crystallinity typically results in slower hydrolysis rates. This resistance extends the physical integrity of the film in soil environments. DSC analysis allows scientists to integrate melting peaks to calculate the percent crystallinity relative to a 100% crystalline standard.

Processing history significantly influences the thermal behavior of agricultural polymers. The thermal history imparted during extrusion or blowing operations can induce orientation and stress, which DSC can reveal through relaxation endotherms. Identifying these thermal history effects ensures that production batches meet consistent quality specifications.

Differential Scanning Calorimetry (DSC) provides critical insights into how materials react to heat, allowing researchers to predict stability and processing conditions.

GEMINI (2026)

Key thermal transitions monitored via DSC:

- Glass Transition (Tg): Indicates the temperature below which the polymer becomes brittle and prone to cracking.

- Melting Temperature (Tm): Determines the upper limit of the polymer's processing and application window.

- Crystallization Temperature (Tc): critical for optimizing cooling rates during the manufacturing of agricultural films.

Laboratory professionals must also account for the impact of plasticizers on thermal transitions. The addition of plasticizers, common in agricultural PVC and bioplastics, lowers the Tg to improve flexibility but can migrate over time. DSC tracking of Tg shifts provides data on plasticizer permanence and the long-term embrittlement risk of the polymer.

Assessing thermal stability of agricultural polymer coatings via TGA

Thermogravimetric Analysis (TGA) determines the degradation temperature and volatile content of polymer coatings used for controlled fertilizer release and seed encapsulation. By monitoring mass loss as a function of temperature, this technique establishes the thermal stability limits necessary for polymer processing and storage. TGA is particularly effective for distinguishing between moisture loss, plasticizer evolution, and polymer backbone degradation.

The kinetics of thermal degradation provide insight into the expected lifespan of agricultural polymers in hot climates. Laboratory professionals utilize variable heating rate experiments to calculate activation energies for decomposition according to ASTM E1641. Furthermore, ASTM E1131 is employed for general compositional analysis, allowing researchers to accurately distinguish between volatiles, combustibles, and ash content. These kinetic parameters model how long a polymer coating will maintain its barrier properties before breaking down.

Compositional analysis of agricultural polymer blends is another primary application of TGA. Many agricultural plastics are composites containing fillers like biochar, natural fibers, or calcium carbonate to reduce costs and modify degradation rates. TGA can quantifiably separate these components based on their distinct decomposition or oxidation temperatures.

Common TGA measurements for agricultural applications:

- Onset Decomposition Temperature: The point where significant chemical breakdown begins.

- Residue Content: The percentage of inorganic filler or ash remaining after combustion.

- Moisture Content: The amount of volatile water, which affects processing quality and hydrolytic stability.

For bioplastics intended for soil incorporation, TGA quantifies the final inorganic residue content. While specific heavy metal analysis requires spectroscopic techniques, TGA provides the essential total ash measurement to confirm the polymer breaks down into organic components without leaving excessive inorganic byproducts. This step is crucial for verifying that the material falls within the inorganic limits specified by compostability mandates.

Evaluating viscoelastic properties of agricultural polymers with DMA

Dynamic Mechanical Analysis (DMA) measures the viscoelastic properties of agricultural polymers to ensure structural integrity across seasonal temperature fluctuations. This technique applies a sinusoidal stress to the sample and measures the resulting strain, allowing for the calculation of storage modulus (stiffness) and loss modulus (damping). DMA is far more sensitive than DSC for detecting subtle glass transitions in highly crystalline or crosslinked agricultural polymers.

The storage modulus serves as a primary indicator of load-bearing capacity for agricultural piping and structural supports. As temperature increases, the storage modulus drops, potentially leading to mechanical failure in irrigation components exposed to direct sunlight. DMA profiles map this stiffness loss, enabling engineers to select materials that maintain rigidity at elevated field temperatures.

Creep compliance and stress relaxation are critical parameters for films and netting under constant tension. DMA instrumentation can mimic long-term loading conditions to predict how a polymer will deform over weeks or months. This data prevents the selection of materials that would sag or fail under their own weight during the growing cycle.

DMA output parameters:

- Storage Modulus (E'): Represents the elastic energy stored in the material.

- Loss Modulus (E''): Represents the energy dissipated as heat.

- Tan Delta (delta): The ratio of loss to storage modulus, indicating damping capability.

Humidity control accessories for DMA allow for the testing of hygroscopic agricultural polymers. Since many biopolymers absorb moisture from the soil or atmosphere, their mechanical properties change drastically with humidity. Testing under controlled relative humidity provides a realistic profile of mechanical performance in wet vs. dry agricultural environments.

Validating biodegradability of agricultural plastics through thermal aging

Thermal analysis plays a supporting role in verifying the material changes associated with international biodegradability standards such as ISO 17088 and ASTM D6400. To simulate the degradation required for industrial composting or soil incorporation, laboratory professionals subject polymer samples to accelerated thermal aging protocols before re-evaluating their physicochemical properties. DSC and TGA are then employed to measure the reduction in molecular weight (inferred from shifts in melting behavior and crystallinity) and structural changes that indicate the onset of fragmentation. Ideally corroborated by chromatography, these thermal indicators track the physical disintegration that precedes the biological mineralization process mandated by regulatory agencies.

Conclusion: Ensuring agricultural polymer quality through thermal analysis

Thermal analysis of agricultural polymers provides the quantitative data necessary to balance durability with biodegradability in modern agriculture. Techniques such as DSC, TGA, and DMA allow laboratory professionals to characterize critical parameters including melting points, degradation kinetics, and viscoelastic behavior. These insights ensure that agricultural films, coatings, and structural components perform reliably in the field while meeting rigorous environmental standards. By rigorously applying these methods, the industry safeguards crop yields and promotes sustainable soil management practices.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.